Method for flattening film layer

A planarization and film layer technology, applied in the field of planarization, can solve the problems of good and bad connection pad quality, affecting thickness uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

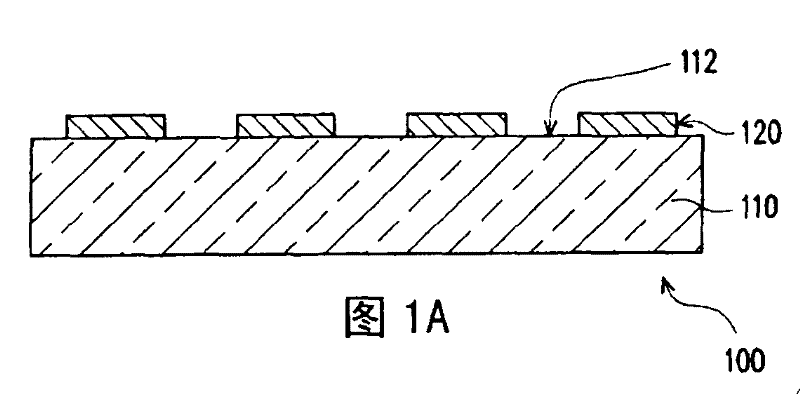

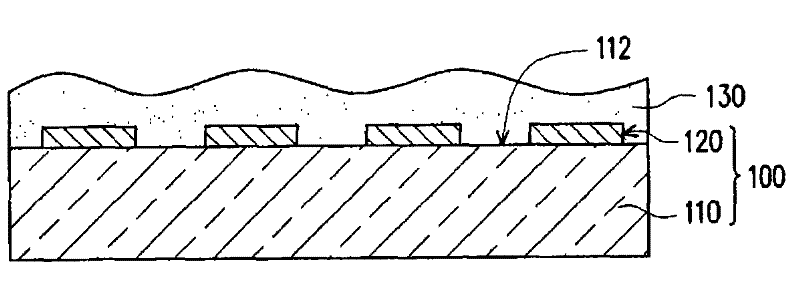

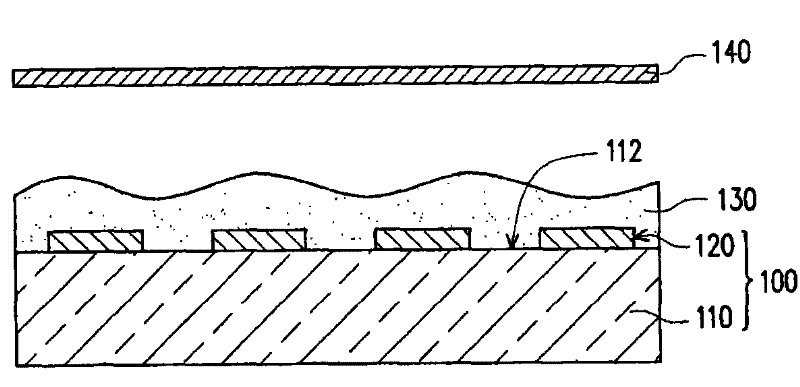

[0031] Figure 1A to Figure 1F It is a schematic cross-sectional view of a method for flattening a film layer according to an embodiment of the present invention. Please refer to Figure 1A Regarding the film planarization method of this embodiment, firstly, a circuit board 100 is provided. The circuit board 100 has a dielectric layer 110 and a patterned circuit layer 120 , wherein the dielectric layer 110 has a surface 112 , and the patterned circuit layer 120 is located on the surface 112 of the dielectric layer 110 .

[0032] It is worth mentioning that the structure of the circuit board 100 may have only one patterned circuit layer 120 , or may have multiple patterned circuit layers. That is, the circuit board 100 may be a single side circuit board, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com