Chrome-based coating film and preparation method thereof

A coating and coating chamber technology, applied in the field of chromium-based coating and its preparation, can solve the problems of many surface defects of the wear-resistant layer of the gravure plate, micro-cracks on the surface, difficulty in thickness uniformity, etc., so as to improve the surface atomic activity, The effect of less surface defects and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

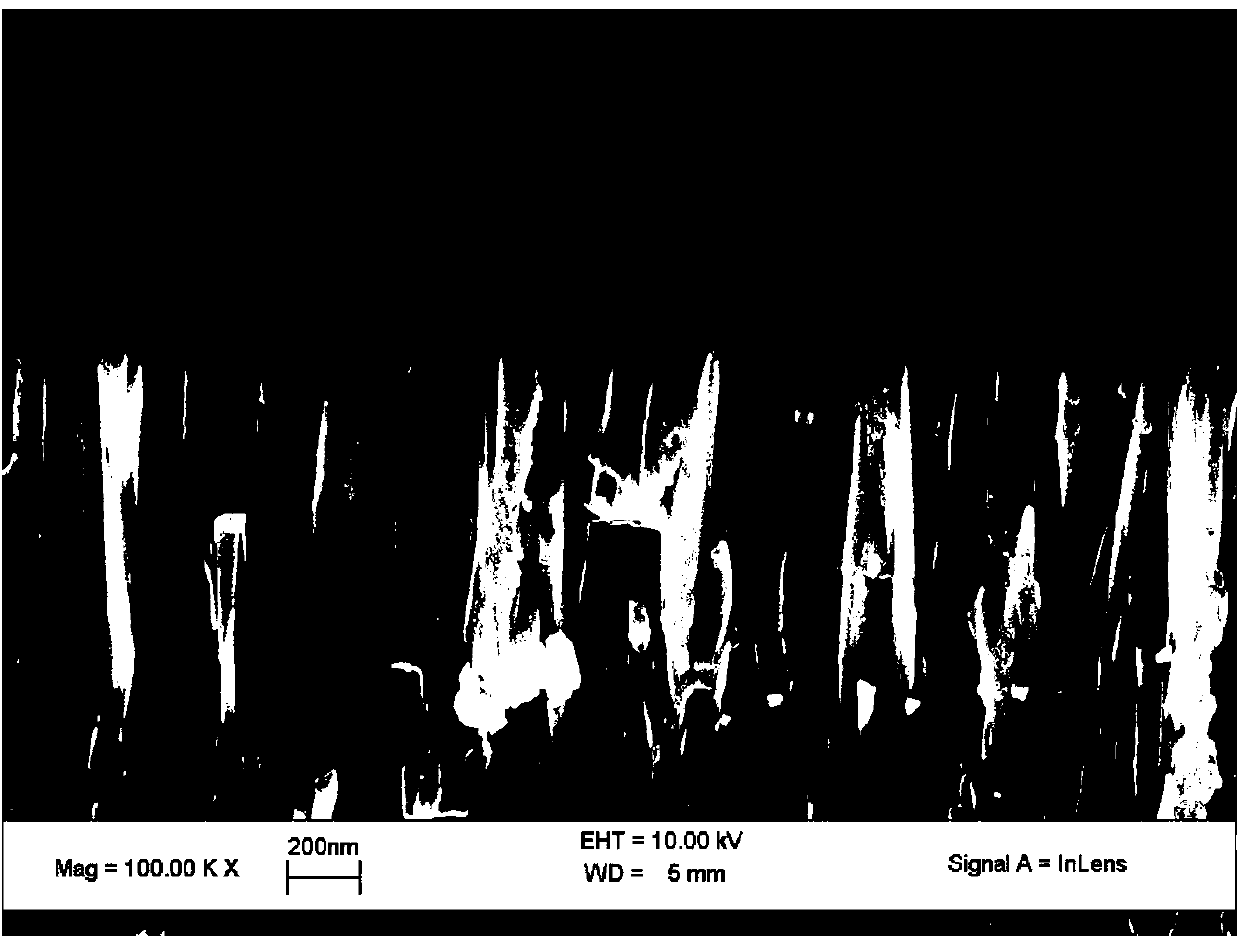

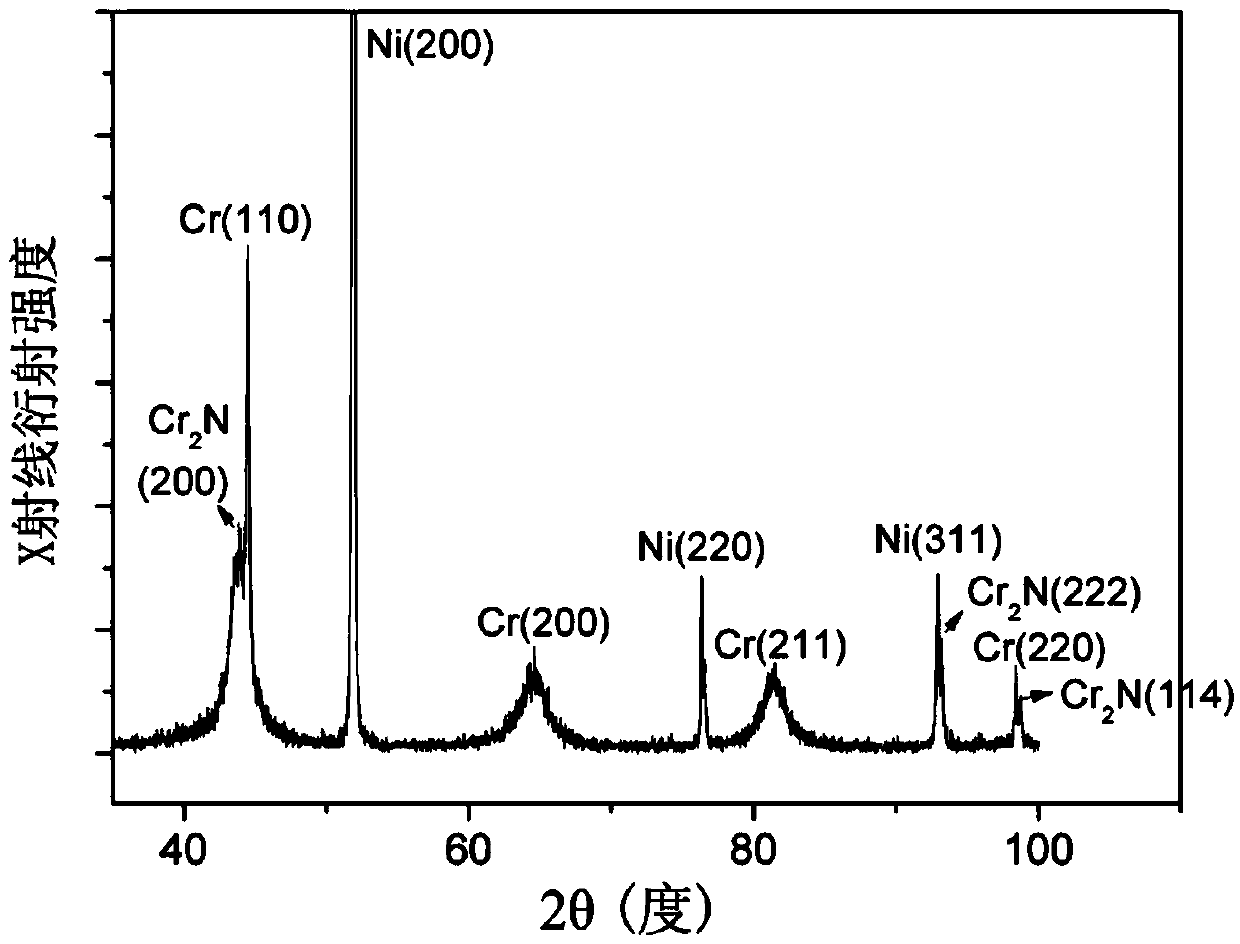

[0034] The present embodiment provides a kind of gravure plate chrome-based coating film, and it is made of Cr-Cr 2 N two-phase compound layer composition, in the two-phase compound layer, Cr and Cr 2 The molar ratio of N is 16:3, which is formed by plating as follows:

[0035](1) In the coating chamber, nitrogen gas and inert working gas argon gas are simultaneously introduced at the flow rates of 90sccm and 110sccm respectively, and magnetron sputtering is used to pass through four pairs of twin chromium columns that are columnar and parallel to each other with a length of 1.5m. Targeting is set on the cooling roller and is plated on the nickel-based gravure metal substrate base material that rotates with the cooling roller, the plating time is 30min, and the plating temperature is 25-100°C (chrome plating process It is the heating process of chromium, so the chromium plating temperature is not a constant value, but a range); the area of the nickel-based gravure metal sub...

Embodiment 2

[0047] This embodiment provides a gravure wear-resistant layer, which includes a Cr transition layer, a chromium-based coating and a Cr smoothing layer, wherein the Cr transition layer is located between the chromium-based coating and the surface of the substrate, and the The Cr smoothing layer is located outside the chromium-based coating, that is, on the side away from the substrate; the thickness ratio of the Cr transition layer, the chromium-based coating, and the Cr smoothing layer is 0.6:10:0.2.

[0048] Wherein, the chromium-based coating is composed of Cr-Cr 2 N two-phase compound layer composition, in the two-phase compound layer, Cr and Cr 2 The molar ratio of N is 10:1, which is formed by plating as follows:

[0049] (1) In the coating chamber, nitrogen and inert working gas argon are introduced at the flow rates of 70sccm and 130sccm at the same time, and the magnetron sputtering method is used to pass through three pairs of twin chromium columns that are columnar...

Embodiment 3

[0055] This embodiment provides a gravure wear-resistant layer, which includes a Cr transition layer, a chromium-based coating and a Cr smoothing layer, wherein the Cr transition layer is located between the chromium-based coating and the surface of the substrate, and the The Cr smoothing layer is located outside the chromium-based coating, that is, on the side away from the substrate; the thickness ratio of the Cr transition layer, the chromium-based coating, and the Cr smoothing layer is 0.2:5.3:0.6.

[0056] Wherein, the chromium-based coating is composed of Cr-Cr 2 The N two-phase compound layer consists of Cr-Cr 2 N two-phase compound layer composition, in the two-phase compound layer, Cr and Cr 2 The molar ratio of N is 17:1, and it is formed by plating as follows:

[0057] (1) In the coating chamber, nitrogen and inert working gas argon are introduced at the same time at flow rates of 30sccm and 170sccm, respectively, and magnetron sputtering is used to pass through f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com