Radiating die set

A heat dissipation module and heat dissipation fin group technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of heat dissipation modules such as heavy weight, large volume, and difficulty in meeting the requirements of light and thin computers , to achieve the effect of simple structure, light and thin, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

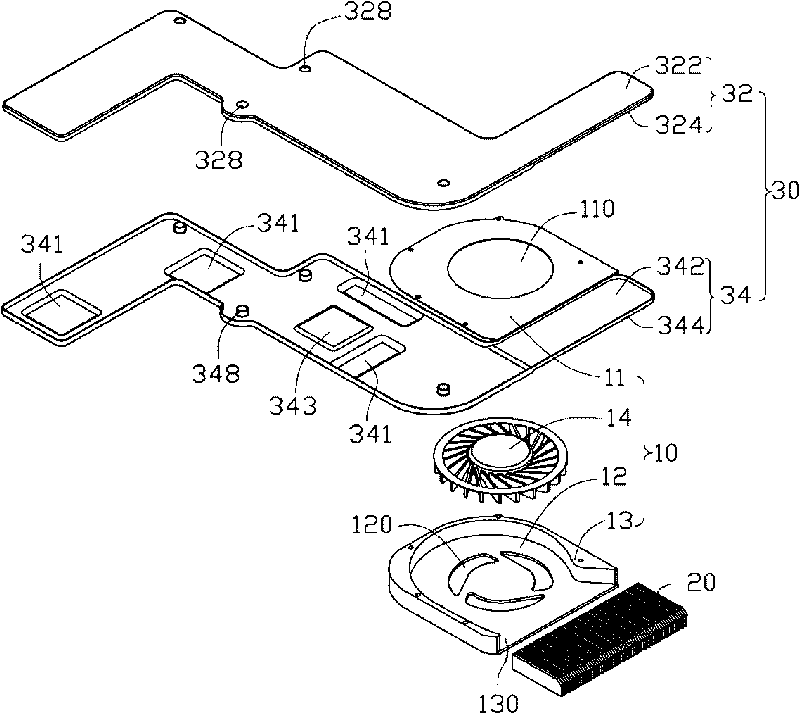

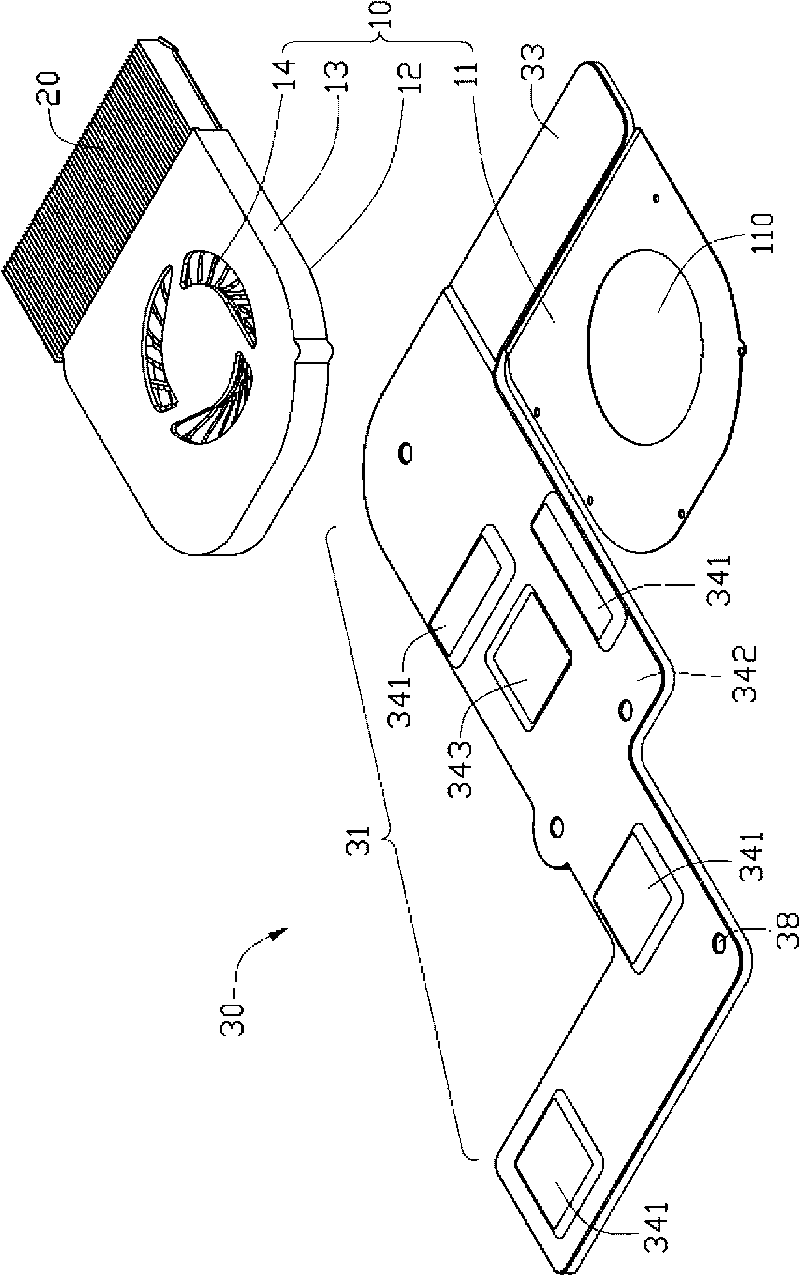

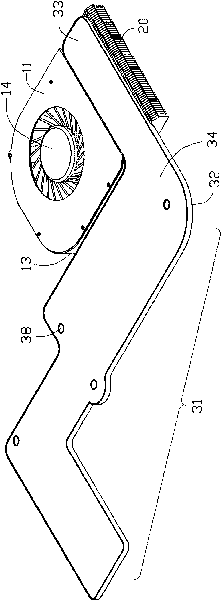

[0011] Please also see Figure 1 to Figure 3 , the cooling module includes a centrifugal fan 10 , a cooling fin set 20 and a plate-type heat pipe 30 .

[0012] The centrifugal fan 10 includes an upper cover 11 , a lower cover 12 , a side wall 13 and an impeller 14 . The upper cover 11 , the lower cover 12 and the side wall 13 enclose and form an accommodating space, and the impeller 14 is accommodated in the accommodating space.

[0013] The upper cover 11 is integrally formed with the heat pipe 30 , and a first air inlet 110 is formed in the middle of the upper cover 11 .

[0014] The outline of the lower cover 12 is similar to that of the upper cover 11 , and a second air inlet 120 is formed in the middle of the lower cover 12 corresponding to the first air inlet 110 . The side wall 13 is located on the outer periphery of the lower cover 12 and is vertically connected with the lower cover 12, so that the side wall 13 and the lower cover 12 encircle to form an accommodating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com