Machine arrangement for machining bar-like workpieces having a device for workpiece support

A technology of mechanical structure and processing rod, which is applied to metal processing mechanical parts, supports, positioning devices, etc., can solve the problem of the immovability of the workpiece seat, and achieve the effect of reliable functional support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

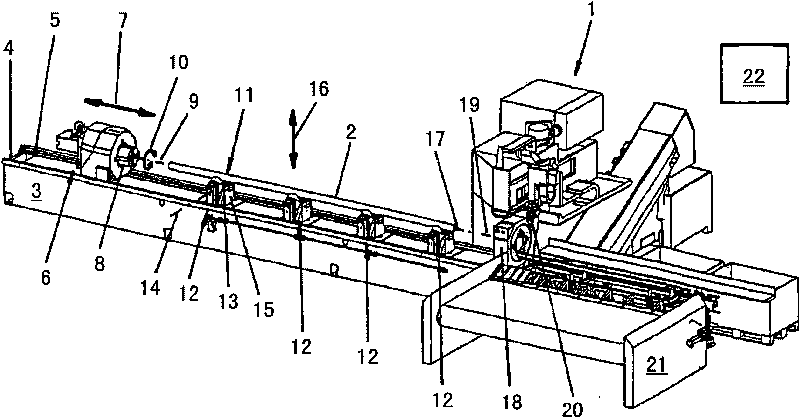

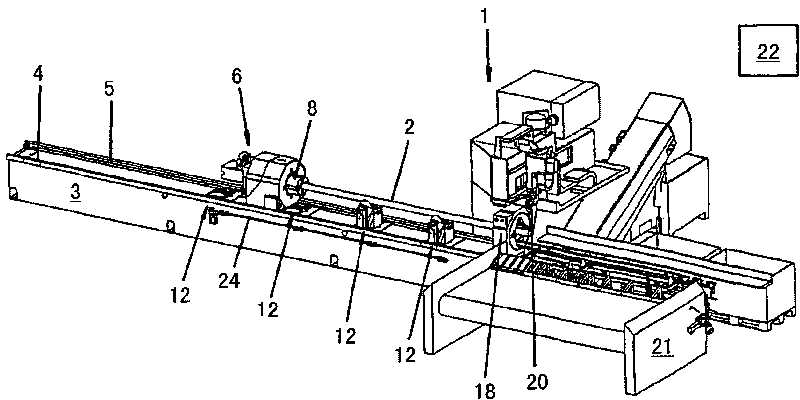

[0027] Such as figure 1 As shown, a machine structure 1 for processing a pipe 2 by cutting comprises a machine bed 3 comprising guide rails 4 for a rotating / feeding station (rotating / feeding table) 6 as workpiece moving means, 5. The rotation / feed station 6 is moved motor-driven on the guide rails 4 , 5 in the direction of the double-headed arrow 7 . On the side facing the tube 2 , the rotation / feed station 6 has a self-centering clamping chunk 8 . The clamping axis 9 of the clamping block 8 , which runs through the clamping center of the clamping block 8 , is indicated by a dotted line. The clamping block 8 can be rotated in a controlled manner about the clamping axis 9 in the direction of the double-headed arrow 10 . figure 1 The clamping block 8 is shown in the open state.

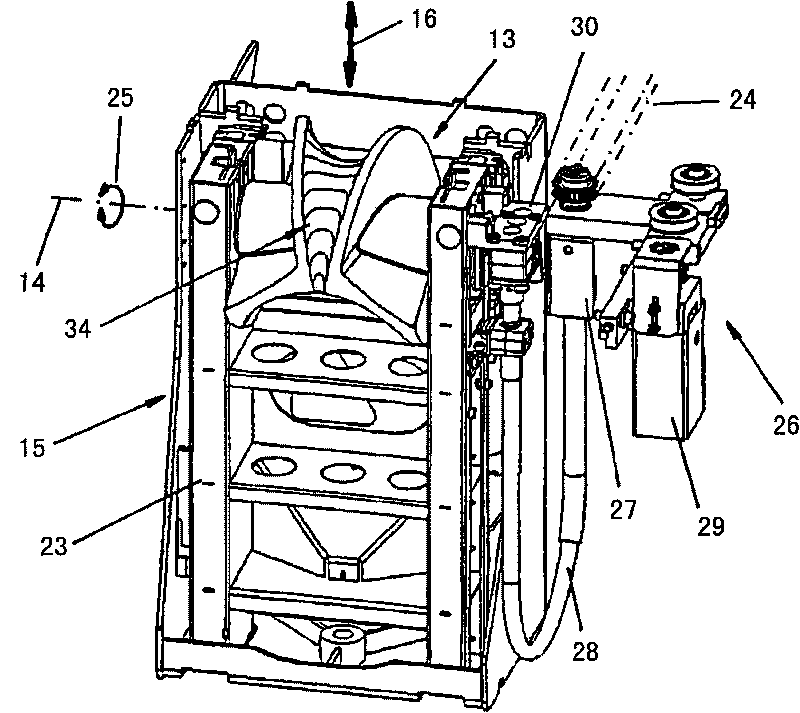

[0028]The tube 2 to be processed is supported against the force of gravity from below by a device 11 for supporting the workpiece, which device 11 is integrally formed in the machine bed 3 . In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com