Roller layered structure of pair-roller-type pelletizer

A technology with a pair of roller granulators and a layered structure, applied in the direction of die extrusion granulation, etc., can solve the problems of insufficient granulation hardness, unsuitable for process automation, and inability to adjust the speed, so as to meet the requirements of particle size and hardness. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

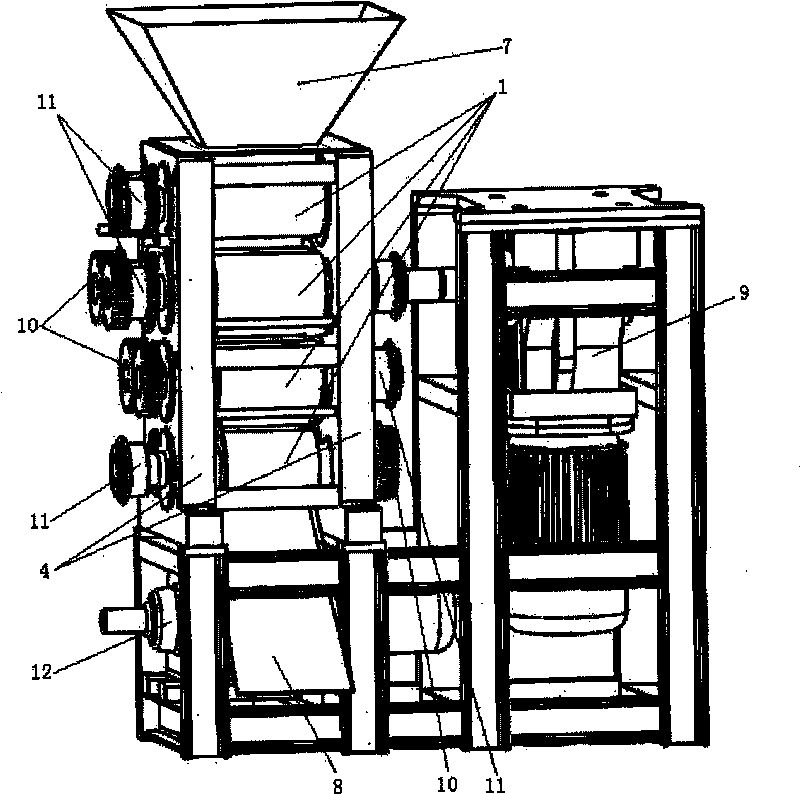

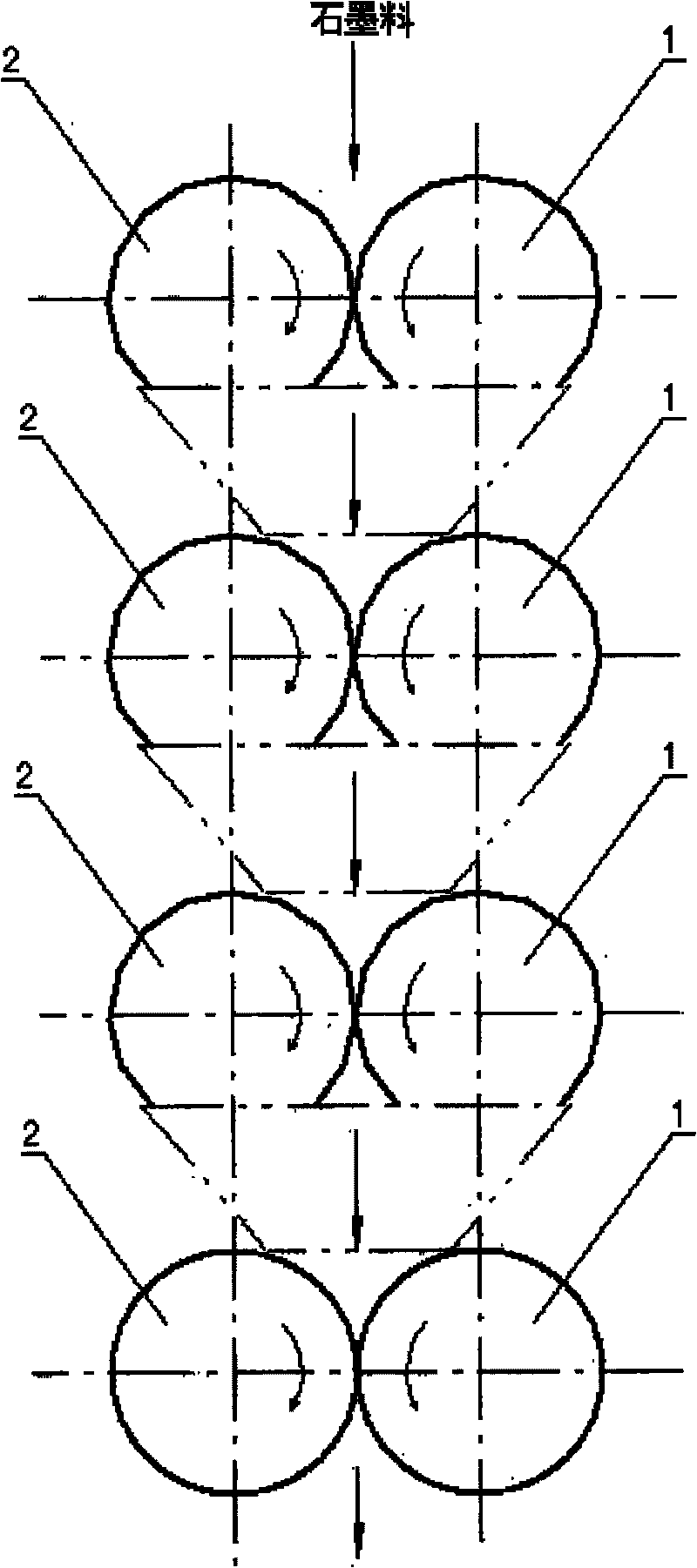

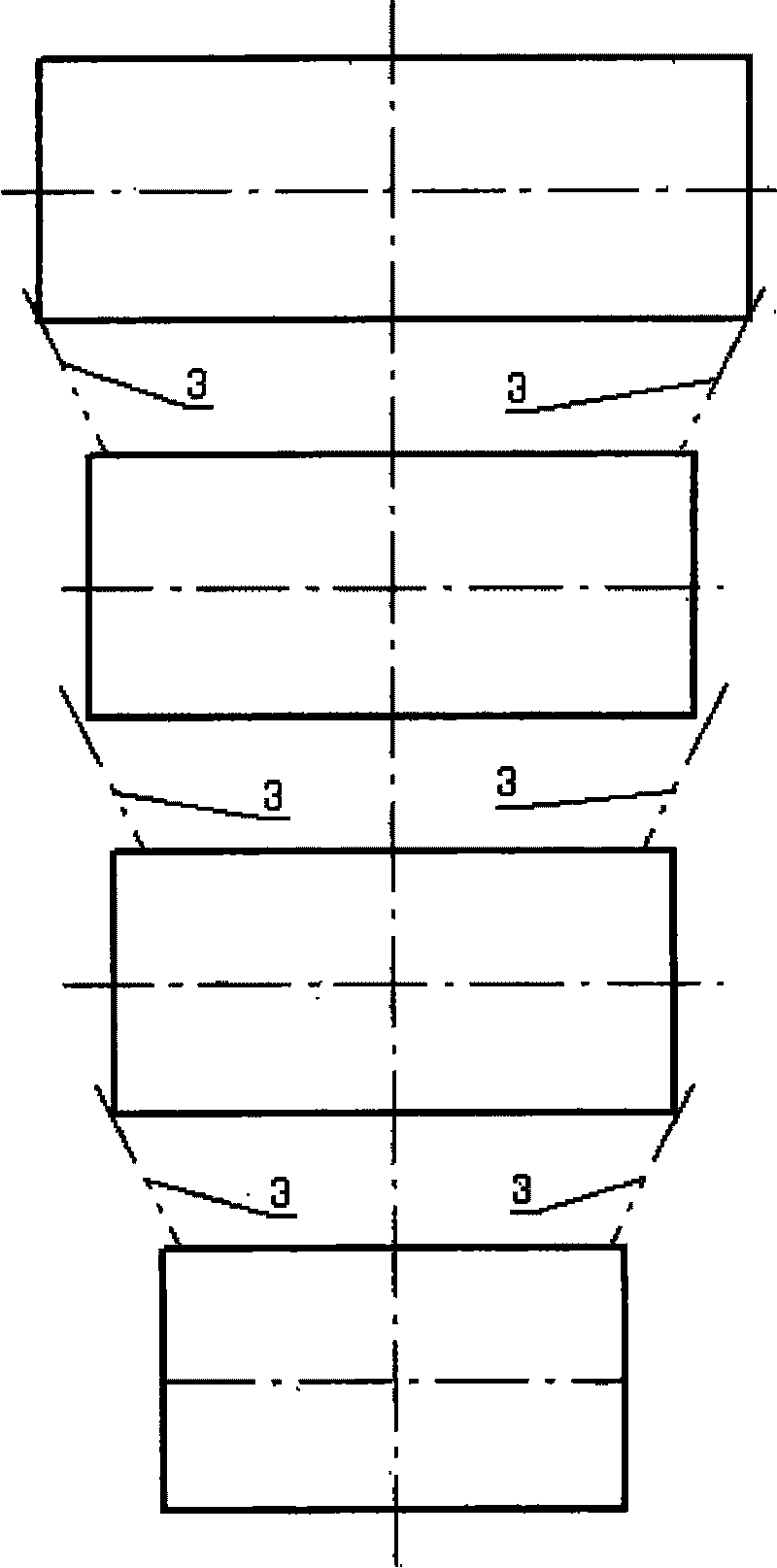

[0023] Such as figure 1 , 2 , 3, 10, and 11 show a roller layered structure of a pair of roller granulators, including rollers arranged on the frame below the feed hopper 7, characterized in that: the frame is arranged in four layers Rollers, each layer is composed of two rollers, the axes of the two rollers are on a horizontal plane, and the rotation direction of each pair of rollers is opposite. , and so on, the bottom of the fourth layer of rollers is the discharge end 8 of the material, and the material is extruded by the fourth layer of rollers, and the two sides of each pair of rollers on the second, third, and fourth layers are installed. The material gathers to the side plate 3 of next layer.

[0024] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, each pair of rollers described is a moving roller 1 and a fixed roller 2, and each layer of fixed rollers 2 is fixedly installed on the side plate 4 through a bearing 6, each The layered moving rollers 1 are first installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com