Method and device for simultaneously carrying out grinding and floatation processes on ultrafine particles

An ultra-fine particle, edge flotation technology, used in flotation, solid waste removal, solid separation, etc., can solve the problems of increasing the torque of the driving mechanism, hindering the design of flotation functions, and low flotation efficiency, and reducing Driving power, saving particle classification device configuration, and facilitating installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

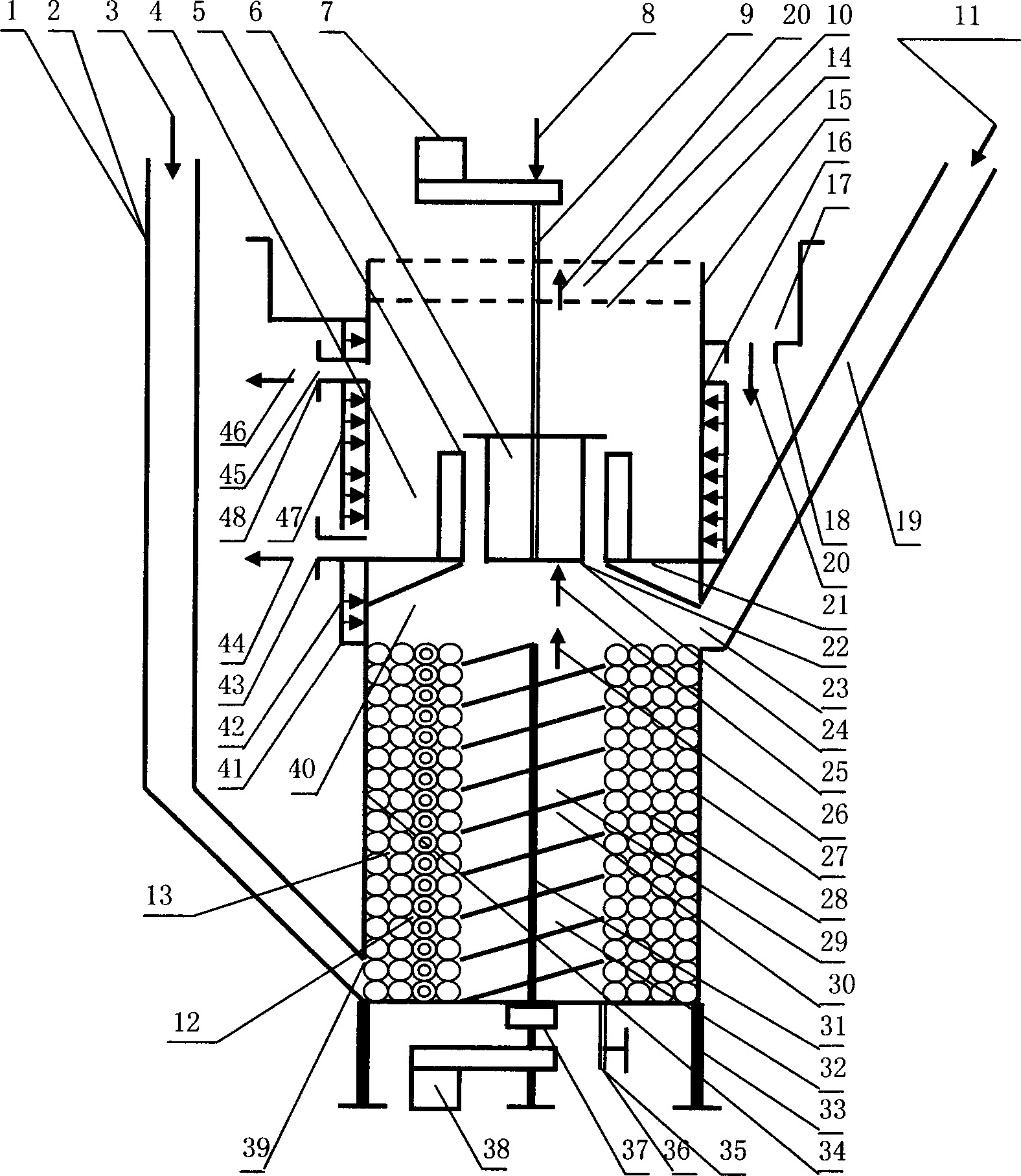

[0036] From attached figure 1 It can be seen that the present invention is an ultrasonic flotation method for ultrafine particles, and adopts the method of integrating the grinding process and the ultrasonic flotation process in the flotation cell body 15, so that the ore pulp 3 to be flotation is located in the flotation tank 15 The vertical grinding functional zone 29 at the lower part of the selection tank enters the flotation tank body, and after the set grinding process, the new grinding slurry 26 is produced; the new grinding slurry enters the upper part of the vertical grinding functional zone. The ultrasonic dispersing functional area 40 in the ultrasonic dispersing functional area 40, after the set ultrasonic dispersing process, the output ultrasonic dispersing pulp 25; the ultrasonic dispersing pulp enters the ultrasonic flotation functional area 4 located on the upper part of the ultrasonic dispersing functional area, and undergoes the set ultrasonic flotation Afte...

Embodiment 2

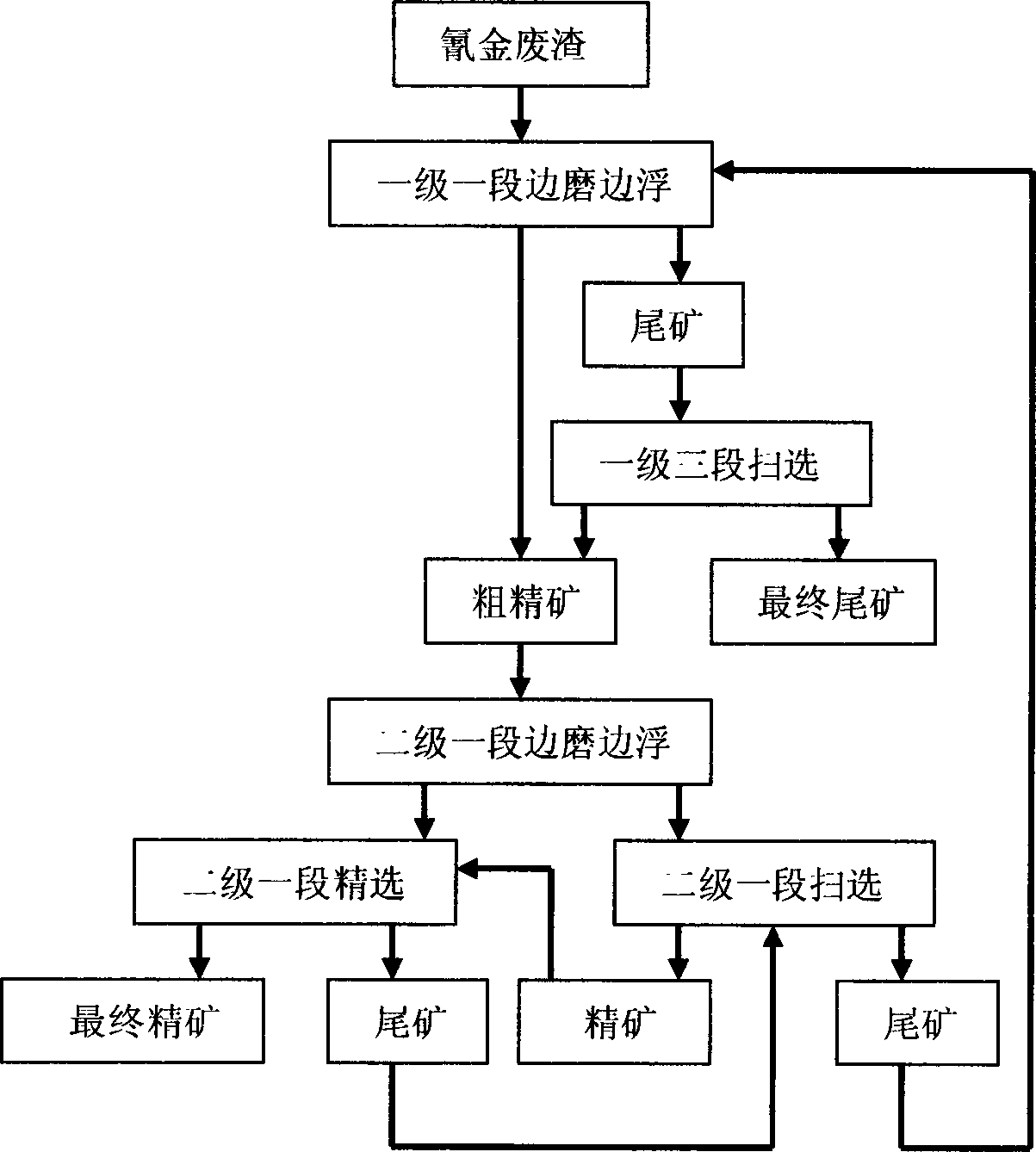

[0047] An ultrasonic flotation process of edge grinding and flotation of cyanogen gold waste slag, the cyanogen gold waste slag contains 4g / t of gold, and the particle size is ≤74um accounting for 100%. Tests have shown that a gold recovery rate of 92.5% can be obtained for a gold concentrate grade ≥ 20 g / t by using a one-stage, one-stage edge-grinding, edge-floating, and ultrasonic flotation process. However, if the grade of gold concentrate is ≤20g / t, or even cyanogen gold waste residue or flotation tailings with a gold content of ≤1g / t, the gold recovery rate of 92.5% cannot be achieved by using the first-stage and one-stage side-grinding and flotation ultrasonic flotation process. , the grade of gold concentrate produced is ≤10g / t. Therefore, it is necessary to apply the grinding-side-floating ultrasonic flotation process for roughing first, and then apply the grinding-side-floating ultrasonic flotation process for the coarse concentrate.

[0048] From attached figure 2...

Embodiment 3

[0058] A side-grinding and floating ultrasonic flotation process of low-grade ultra-fine zinc oxide ore, zinc oxide ore contains zinc ≤ 6%, particle size ≤ 74um accounts for 80%, and mud content 10-30%. The test shows that the zinc oxide ore with high mudification rate is suitable for the ultrasonic flotation process in which the muddy zinc oxide ore is separated separately and the zinc oxide ore is ground and floated after desliming.

[0059] The edge-grinding-float ultrasonic flotation process of ultra-fine zinc oxide ore, the technical principle is the same as embodiment one, but its ultrasonic sound intensity parameter is set as 10-50% of embodiment one; It is 150-300% of Embodiment 1; under the same conditions of grinding intensity and grinding time parameters, the processing amount of pulp to be flotation is set as 150-300% of Embodiment 1.

[0060] Test results: zinc recovery rate 83-85%, zinc concentrate grade 33-36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com