Gate valve rod screw processing single purpose machine

A thread processing and special-purpose machine tool technology, which is applied in metal processing equipment, thread cutting machines, manufacturing tools, etc., can solve the problems of low production efficiency and high processing cost, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

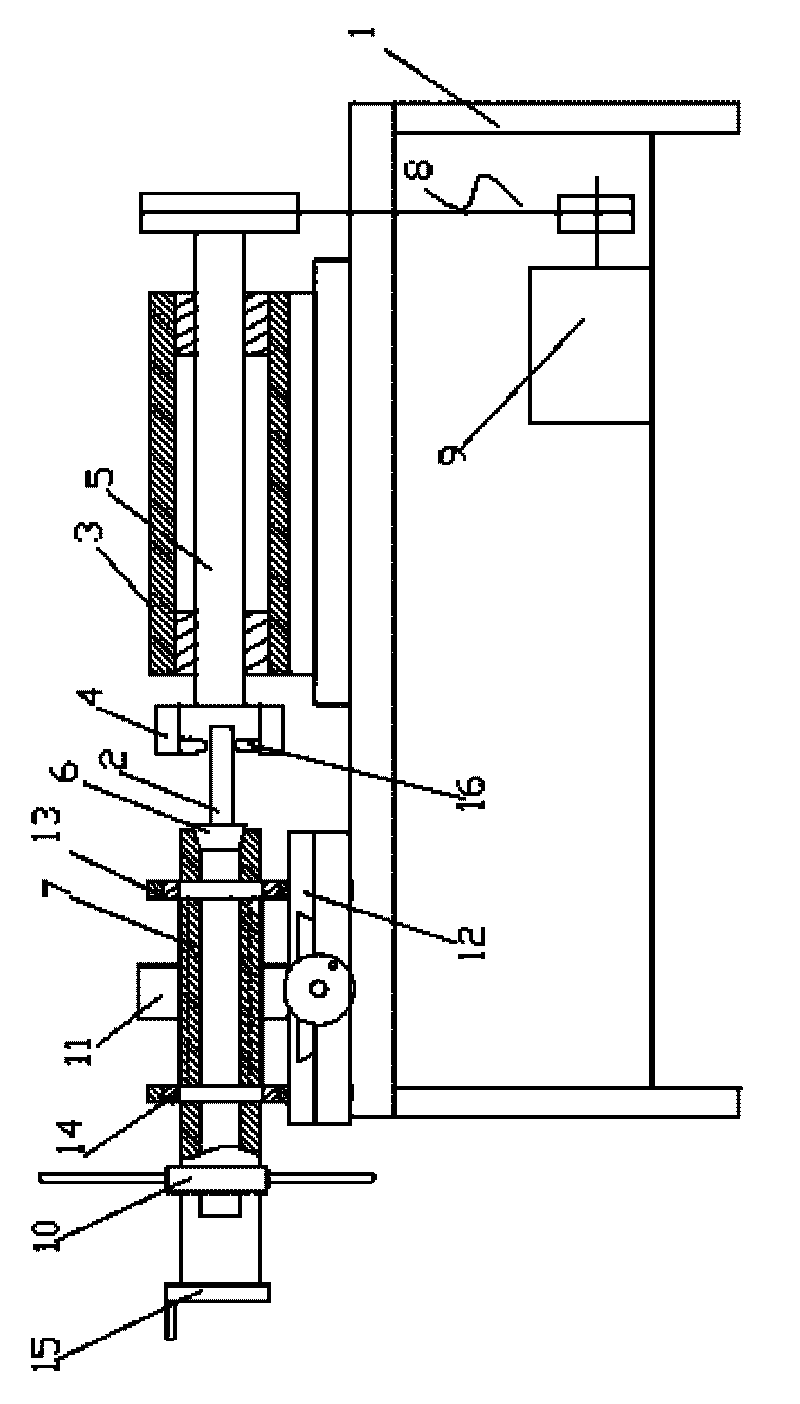

[0011] See the accompanying drawings for details, a special machine tool for gate valve stem thread processing, mainly composed of a frame 1, a transmission mechanism 2, a spindle box 3 fixed to the frame, a spindle 5 equipped with a cutter head 4, a spring chuck 6 and The pitch master hollow shaft 7 is composed of the main shaft with the cutter head mounted on the bearing of the main shaft box, the main shaft is connected with the motor 9 through the belt transmission pair 8, and the taper at the front end of the spring chuck is consistent with the pitch master hollow shaft. The taper of the front port is matched, and the spring chuck passes through the hollow shaft of the pitch profiler, and the rear end is screwed with a lock nut 10 . The outer circle of the pitch cam hollow shaft is provided with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com