Device for eliminating back clearance of X-shaft drive gear box of machine tool

A gearbox and X-axis technology, which is applied in the field of machine tools, can solve problems affecting the motion accuracy and service life of the X-axis transmission gearbox, and achieve the effect of eliminating motion accuracy and service life, and eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

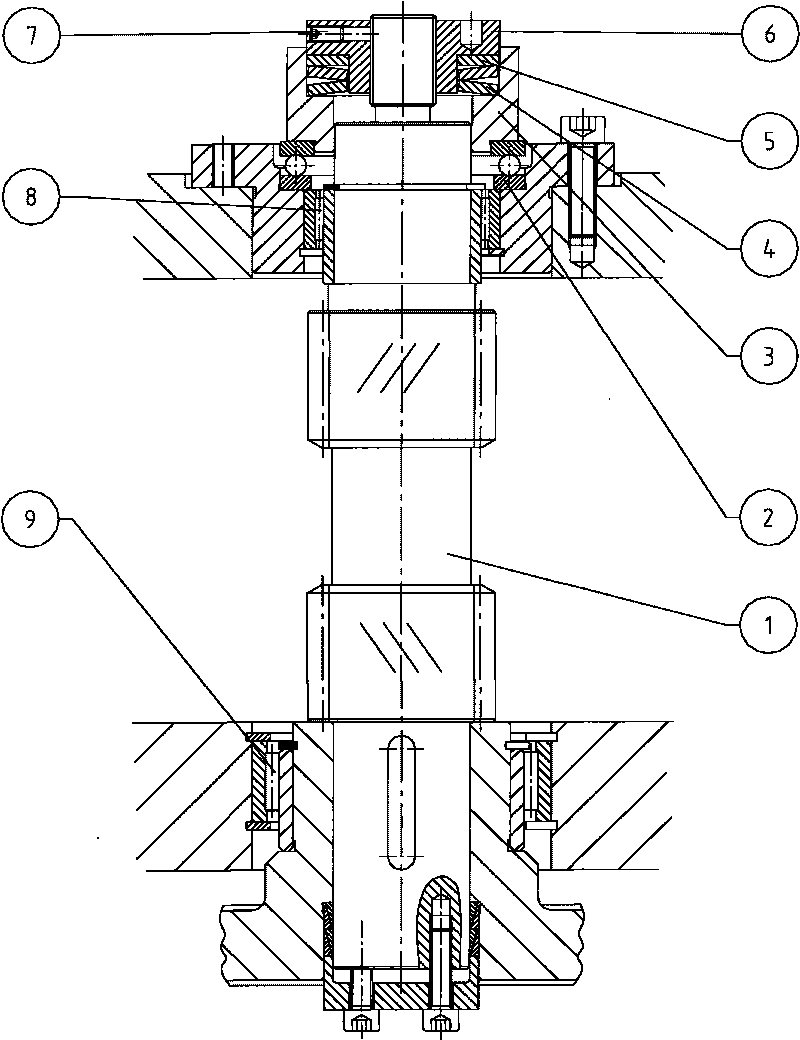

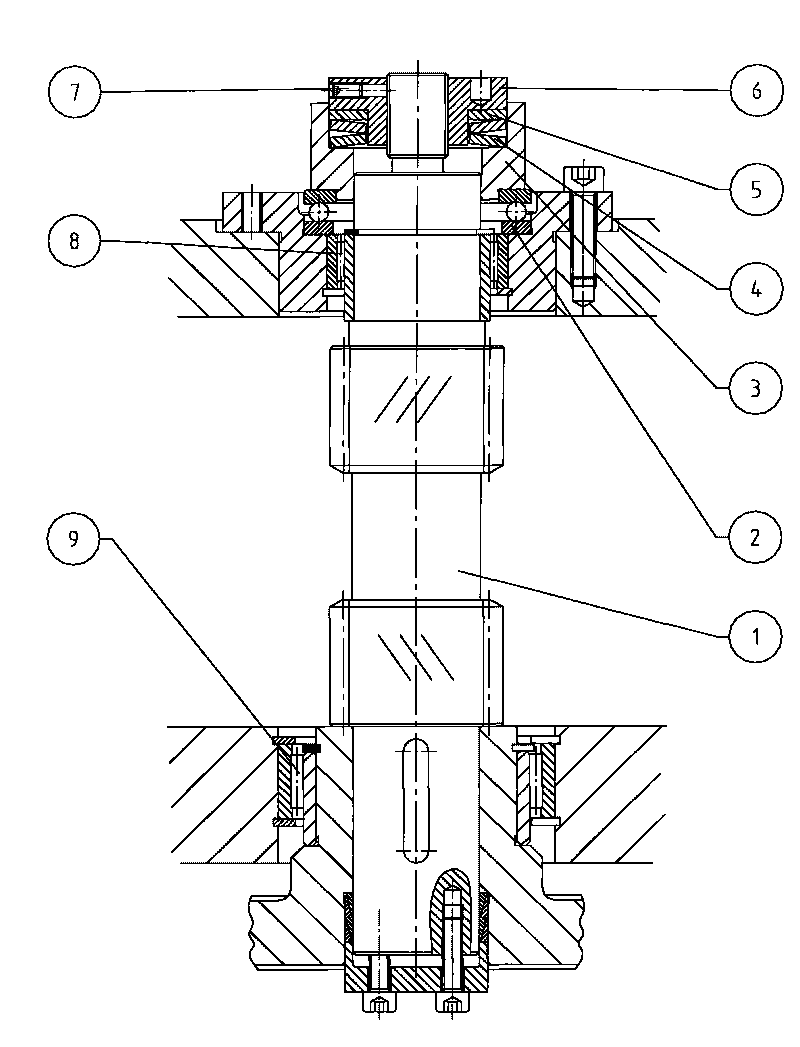

[0010] exist figure 1 Among them, the present invention is provided with a gear shaft 2, the gear shaft 2 is jointly supported by the upper needle roller bearing 8 and the lower needle roller bearing 9, a thrust bearing 2 is fixed on the gear shaft 1 on the upper side of the upper needle roller bearing 8, and the upper end of the thrust bearing 2 A cover 3 is set on the gear shaft 1 of the cover 3, a disc spring 4 is installed in the inner cavity of the cover 3, a pad 5 is arranged above the disc spring 4, a nut 6 is screwed on the end of the gear shaft 1, and the nut 6 holds the disc through the pad 5. The shape spring 4 is compressed in the cover 3, and the radial direction of the nut 6 is processed with a threaded through hole, and a set screw 7 is screwed in the through hole.

[0011] When the present invention wants to eliminate the backlash, loosen the set screw 7, turn the nut 6 with a special wrench and press the disk spring 4 through the pad 5, the axial degree of fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com