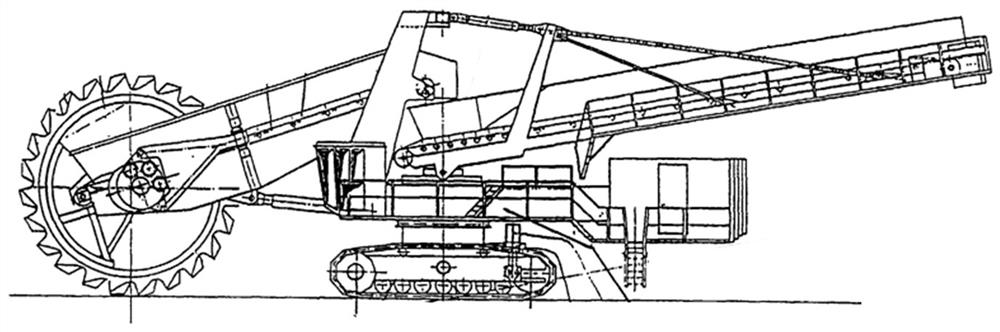

Discharging arm slewing mechanism for wheel bucket excavator

A slewing mechanism and unloading arm technology, applied in mechanically driven excavators/dredgers, etc., can solve problems such as difficulty in meeting the requirements of super-large machinery to resist rigid impact, environmental temperature and humidity effects, and inability to fully cope with complex external environments, etc. Achieve the effect of good safety, simple and compact structure, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

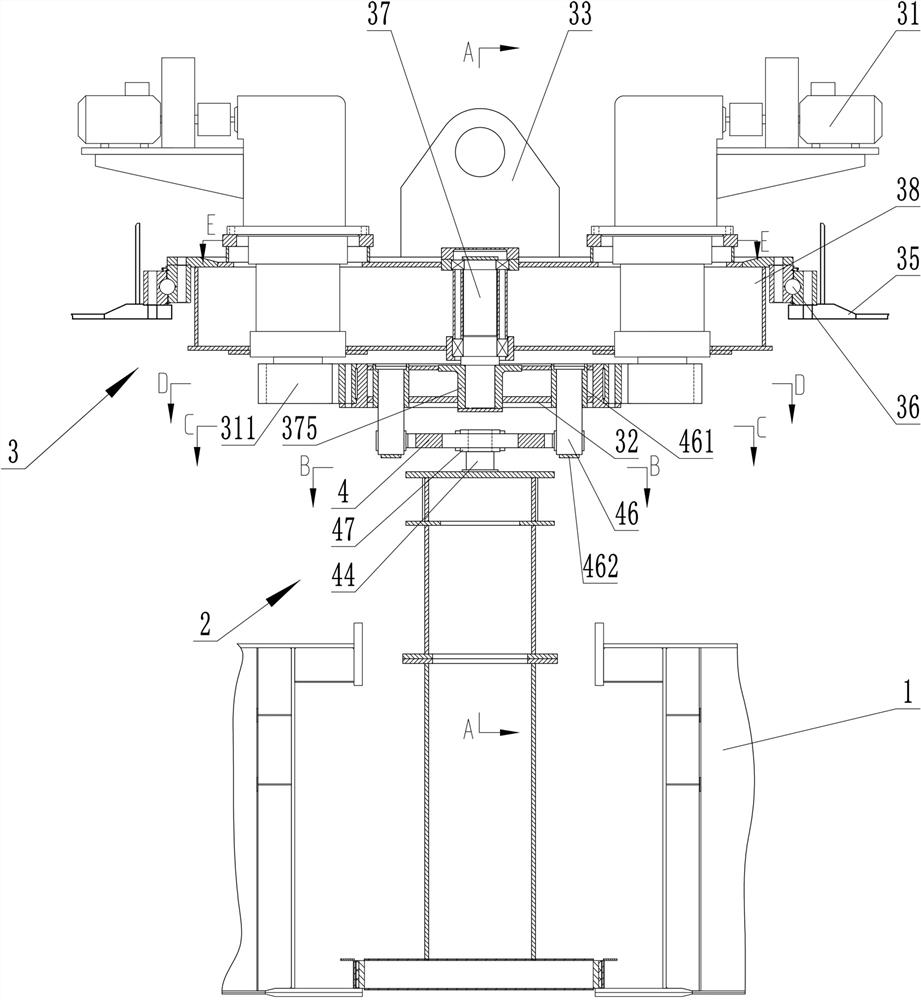

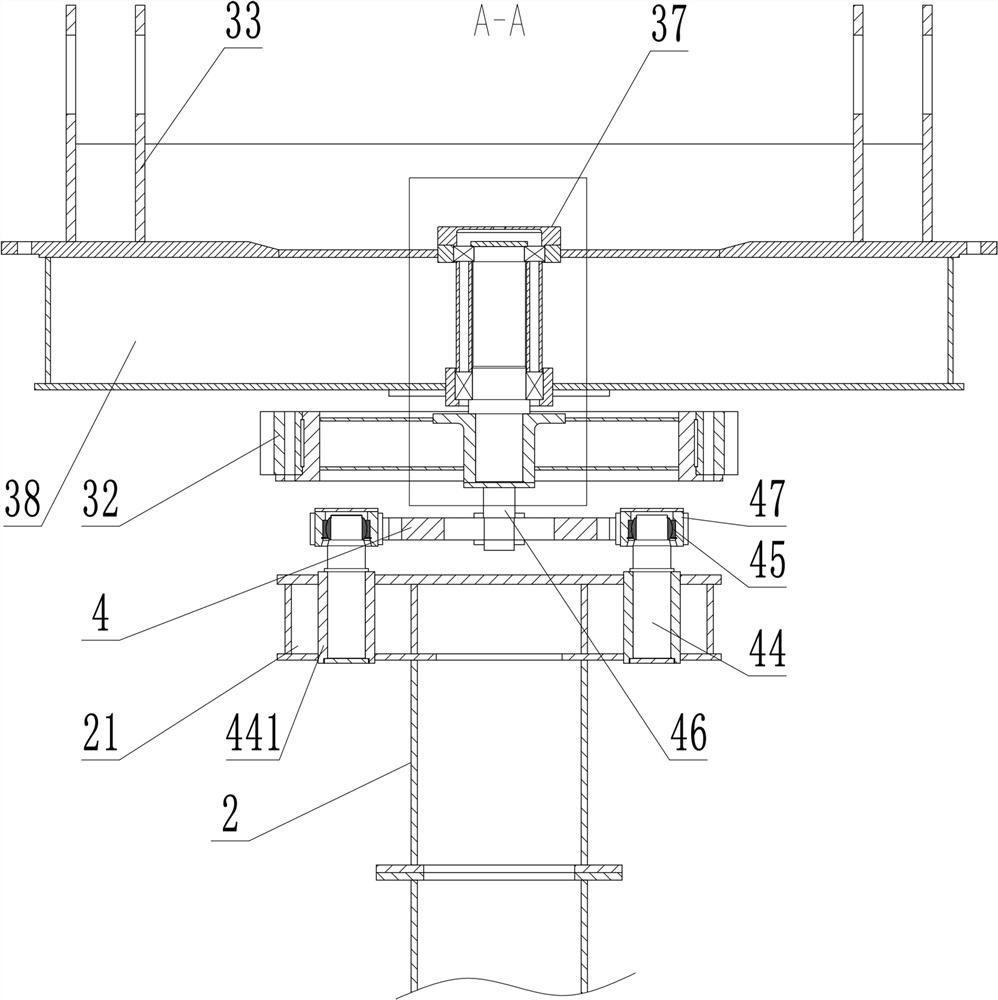

[0029] Combine the following Figure 2~6 , the specific content of the present invention will be described in detail through specific embodiments.

[0030] Unloading arm rotation mechanism]

[0031] Such as figure 2 and Figure 2A As shown, the discharge arm slewing mechanism for a bucket wheel excavator mainly includes a support base assembly 2 , an adjustment plate assembly 4 , and an adjustment slewing support assembly 3 from bottom to top. The support base assembly 2 is fixed on the walking mechanism 1 of the equipment itself, and the adjustment plate assembly 4 can rotate the support assembly 3 and the support base assembly 2 automatically through two pairs of upper connecting shafts 46 and lower connecting shafts 44 that are vertically intersected by two pairs of axis lines. Connect adaptively.

[0032] Figure 2A-1 As shown, the center of rotation of the inner turntable 38 is equipped with a freely rotatable central shaft assembly 37. The central shaft assembly 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com