High-pressure direct-injection natural gas engine gas inlet pressure stabilizing device based on variable coherent wavelength

A technology of air intake pressure stabilization and natural gas, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of reducing the control accuracy of the electronic control system, affecting engine combustion and emissions, and being unable to accurately measure the gas consumption rate, etc., to achieve Eliminate the difference in injection quantity controlled by the electronic control system, improve combustion and emissions, and eliminate the effect of pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

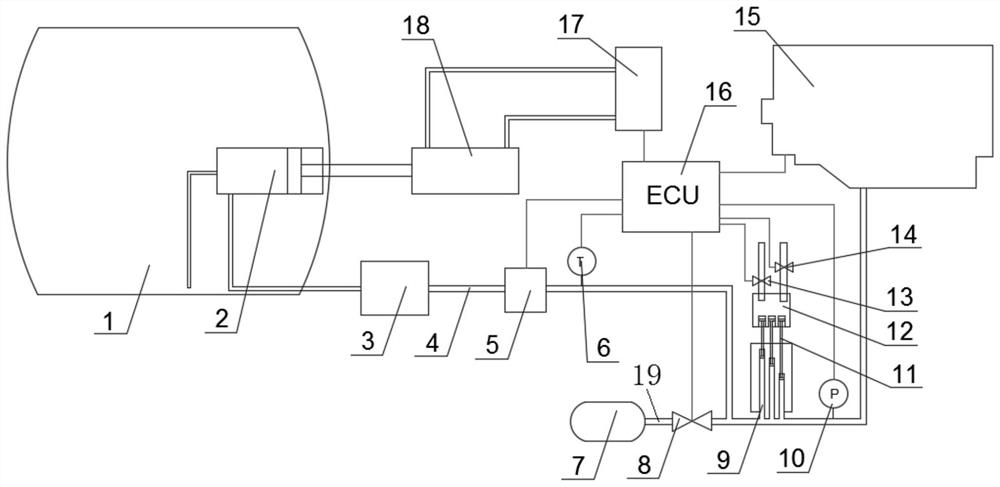

[0014] The present invention provides a high-pressure direct-injection natural gas engine intake pressure stabilizing device (referred to as the device, see figure 1 ), including LNG tank 1, LNG plunger pump 2, LNG carburetor 3, first high-pressure natural gas pipeline 4, electric control unit 16, hydraulic pump flow regulator 17 and hydraulic pump drive unit 18; said LNG plunger pump 2 Set in the LNG tank 1; the LNG plunger pump 2 is connected to the LNG carburetor 3 through the LNG high-pressure pipeline; the LNG carburetor 3 is connected to the high-pressure direct injection natural gas engine 15 through the first high-pressure natural gas pipeline 4;

[0015] It is characterized in that the device also includes a natural gas pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com