Pressure control method and identification system of pressure control valve inside hydraulic system of transmission

A technology of transmission control and pressure control, which is applied in the direction of transmission control, valve operation/release device, valve details, etc. It can solve the problems of low control accuracy and poor interchangeability, so as to ensure control accuracy, improve control efficiency, The effect of improving versatility and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

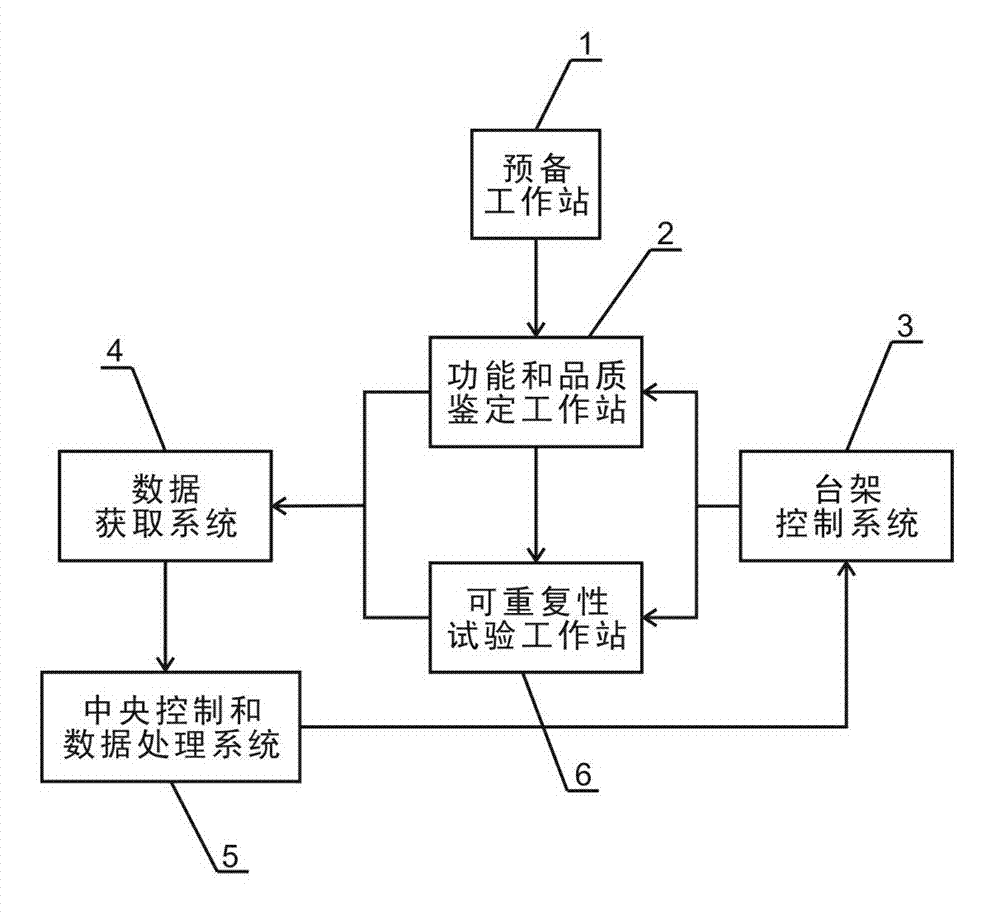

[0029] The control method of an electromagnetically controlled pressure control valve of the present invention is first to identify the quality and performance of the valve through a quality identification system on the production line, in addition to the conventional detection of content such as pipeline leakage, resistance, etc. In addition, it is particularly necessary to detect the corresponding output pressure of the valve under a certain input current. In order to complete the quality appraisal of the valve, the quality appraisal system adopted in the present invention is as follows: figure 1 As shown, it includes a preparatory workstation 1, a functional and quality appraisal workstation 2, a bench control system 3, a data acquisition system 4, and a central control and data processing system 5. The preparatory workstation first appraises the appearance of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com