Electropneumatic transducer with a pneumatic pressure-regulating valve

A technology of pressure regulation and converter, which is applied in the direction of physical quantity changer, auxiliary non-electric fluid pressure control, mechanical equipment, etc., which can solve the problems of high manufacturing cost and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

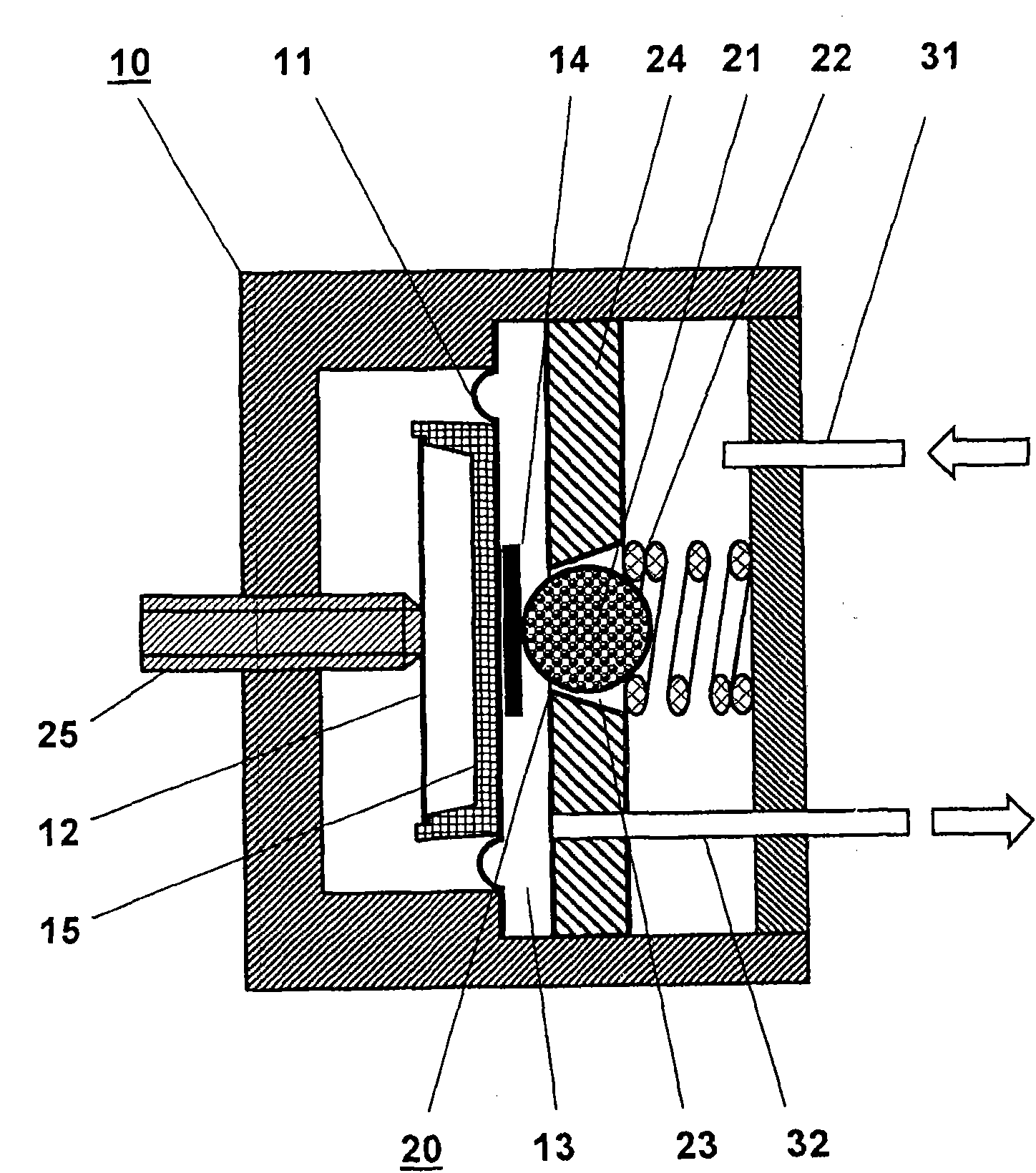

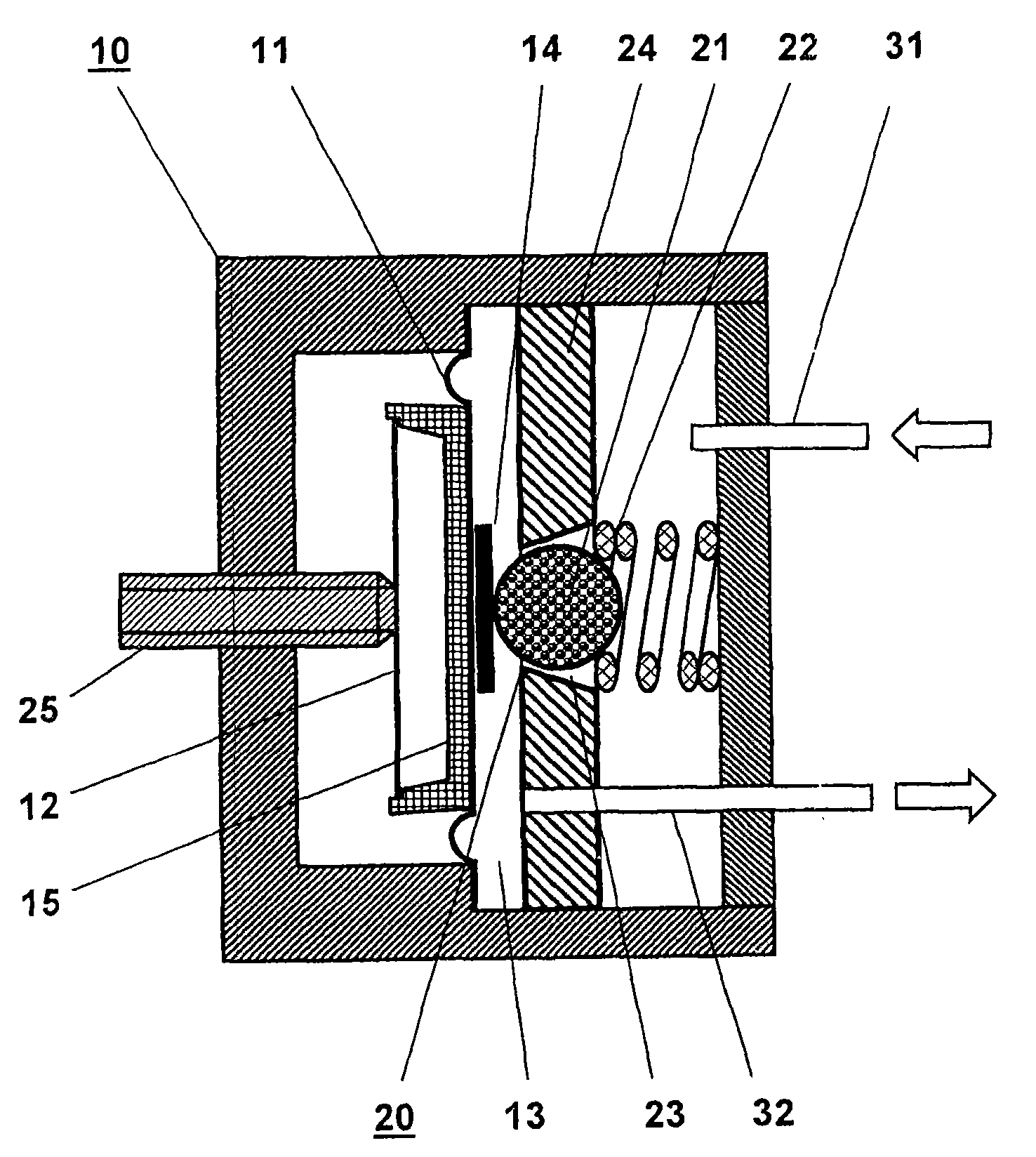

[0022] figure 1 is a cross-sectional view of the electropneumatic converter 10 with a pneumatic pressure regulating valve. The pressure regulating valve has a pressure chamber 13 which is closed off by a regulating diaphragm 11 and a housing wall 24 opposite the regulating diaphragm.

[0023] Arranged in the housing wall 24 is a control valve 20 which consists of a dimensionally stable ball 21 which is loaded by a spring 22 and which is situated in a conical bore 23 which narrows in the direction of the regulating diaphragm 11 . Unregulated pressure medium 31 is fed towards the side of the ball 21 facing the spring 22 .

[0024] The adjusting diaphragm 11 is supported in a non-positive manner on a pressure plate 15 which is connected to a rotationally symmetrical adjusting spring 12 . The center of gravity of the adjustment spring 12 is supported on the adjustment screw 25 .

[0025] According to a first embodiment of the invention, the pressure plate 15 is designed as an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com