Automatic container cutting device

A cutting device and container technology, applied in shearing devices, accessories of shearing machines, tools for shearing machines, etc., can solve the problem of low degree of automation, incomplete cutting, inability to use vacuum environment or fully automated platform, etc. problems, to achieve the effect of high degree of automation, saving manpower, eliminating overload torque and incomplete cutting or poor cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

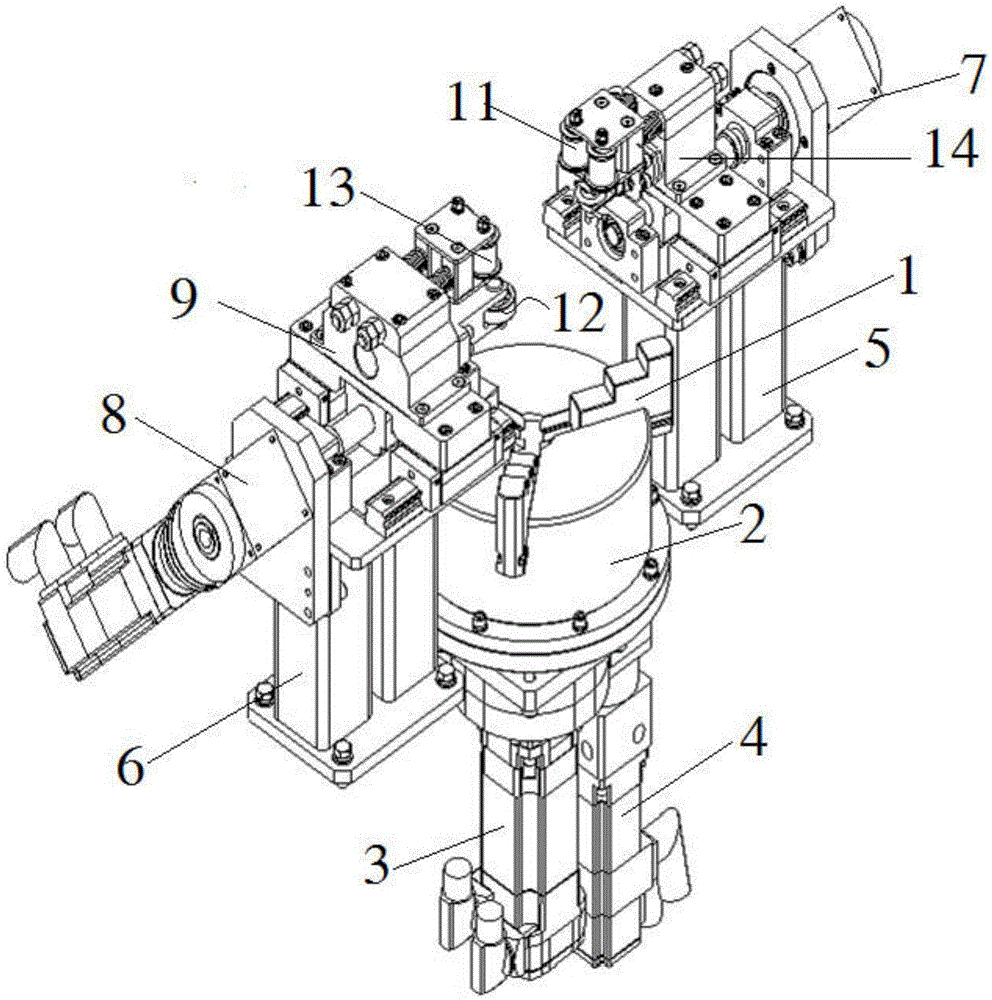

[0037] Embodiment 1: as figure 1 , figure 2 As shown, an automatic container cutting device includes a three-jaw chuck for placing tank containers, a cutting unit 14, a controller, a first mounting base 5, and a second mounting base 6,

[0038] The three-jaw chuck includes a jaw 1 and a chuck body 2, the chuck body 2 is driven by a first drive motor 3 to realize rotation and speed change, and the jaw 1 is driven by a second drive motor 4 to realize inward or move outward;

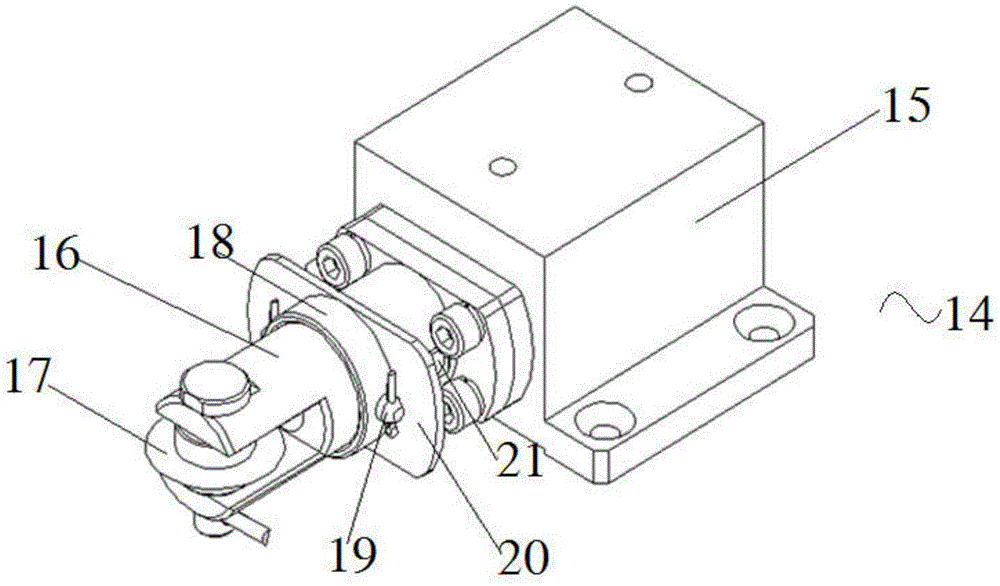

[0039] The cutting unit 14 includes a knife bar mount 15 and a knife bar 16, the knife bar 16 is installed on the knife bar mount 15, and a cutting blade 17 is installed on the knife bar 16;

[0040] The first installation base 5 is provided with a linear guide rail, and the bottom of the knife bar mounting seat 15 is provided with a slider that matches the linear guide rail, and the knife bar mounting seat 15 is driven by the third drive motor The block moves along the linear guide rail;

[0041] The se...

Embodiment 2

[0047] Embodiment 2: as figure 1 , figure 2 As shown, an automatic container cutting device is different from Embodiment 1 in that the container cutting device also includes a clamping assembly, and the clamping assembly includes a first clamping part 11 for contacting with the tank container And the second clamping part 13, the first clamping part 11 is installed on the cutting unit 14, the second clamping part 13 is installed on the clamping mechanism 9, the first clamping part 11 and the second The parts in the clamping part 13 that are used to be in contact with the tank container are rollers, the number of rollers in each clamping part is 2, and the contact elements 12 on the clamping mechanism 9 are rollers. Wherein, the arrangement of each clamping portion and the rollers in the tightening mechanism 9 makes the rotation resistance of the tank container during the rotation process smaller. The arrangement of the first clamping part 11 and the second clamping part 13 c...

Embodiment 3

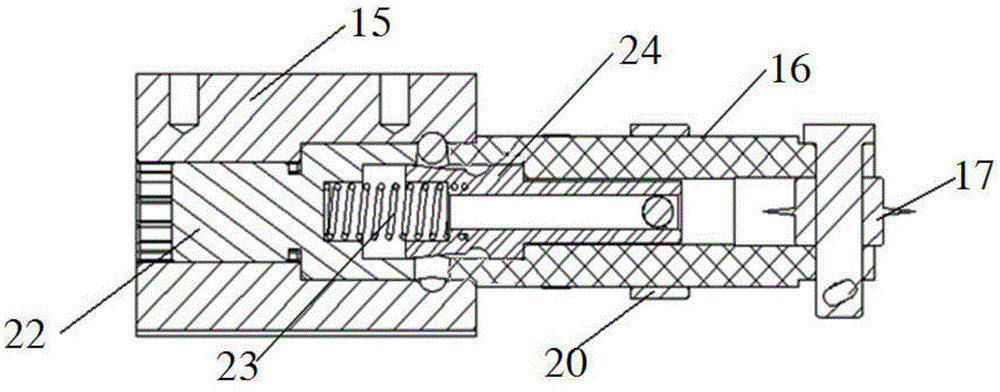

[0049] Embodiment 3: as Figure 1 to Figure 4 As shown, an automatic container cutting device differs from Embodiment 1 or Embodiment 2 in that the cutting unit 14 also includes a spline shaft 22 and a spring 23, and the spline shaft 22 is connected to the cutter bar 16, The inside of the knife rod 16 is sleeved with a knife rod mandrel 24, and one end of the knife bar mandrel 24 is equipped with a push rod 19, and the said knife rod 16 is provided with a chute 21, and the said push rod 19 extends through the chute 21 to Outside the knife bar 16, the other end of the knife bar mandrel 24 is a steel ball positioning arc-shaped groove 242 and a tapered surface structure 243 that gradually increases in taper. The steel ball positioning arc-shaped groove 242 is provided with several steel balls. The spline shaft 22 is provided with a plurality of steel ball positioning holes, and the spring 23 is in contact with the spline shaft 22 and the knife bar core 24 respectively. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com