Grinding wheel cutting device

A grinding wheel cutting machine, cutting saw technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of unsafe hidden danger, uneven end face of cutting parts, inconvenient quality inspection, etc., to ensure cutting quality, easy to Operation, to avoid the effect of uneven end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

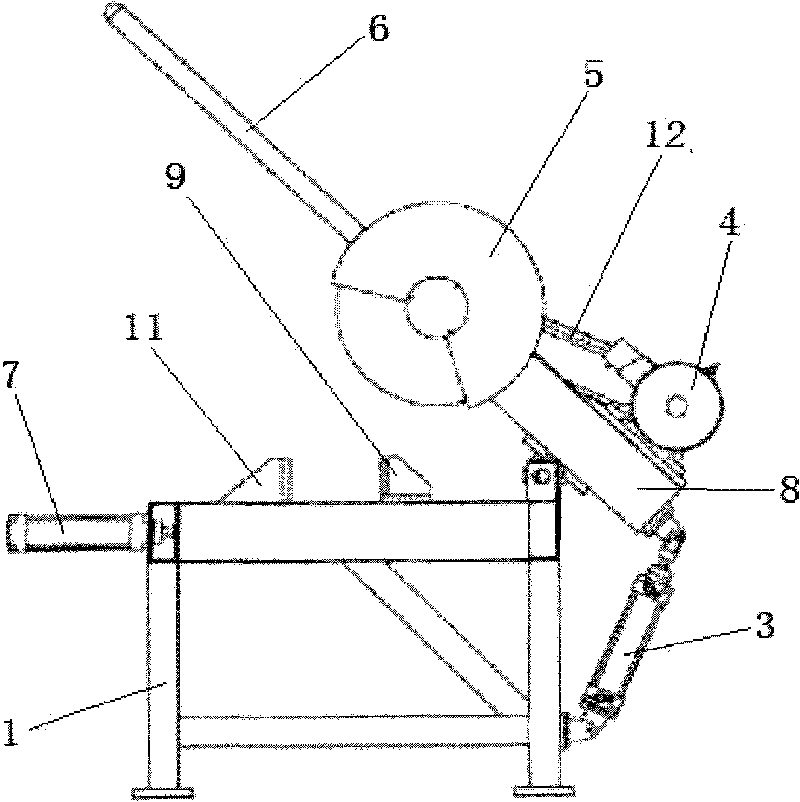

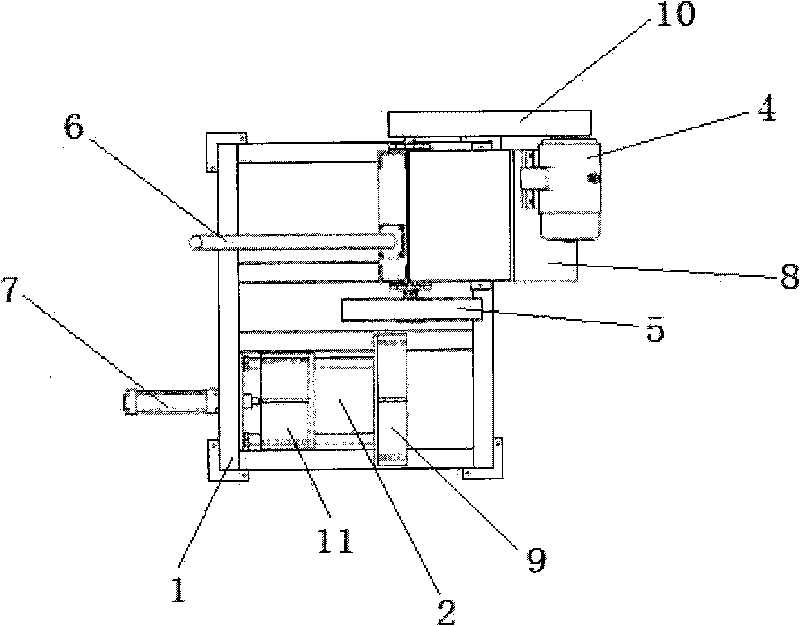

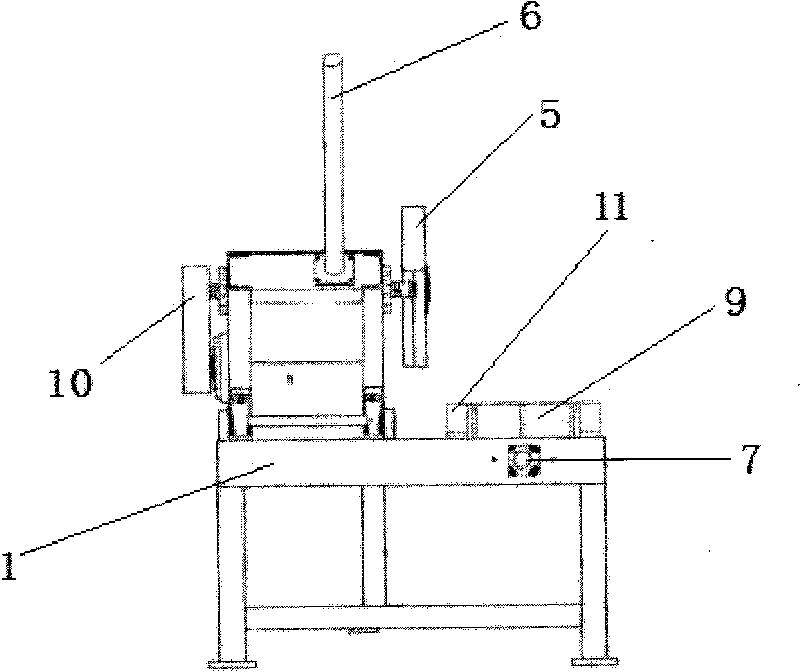

[0014] Such as figure 1 As shown, including the bracket 1, the cylinder 2 provided on the working platform of the bracket 1 is provided with a fixed splint 9 and a movable splint 11, and the movable splint 11 is connected with the adjusting screw 7, and when the cylinder 2 is inflated, the movable splint 11 will be Slowly move toward the fixed splint 9, so that the cutting piece can be clamped. If the cylinder is not used to inflate, the adjusting screw 7 can be used to adjust the moving splint 11 so that the moving splint 11 moves toward the fixed splint 9, so that the cutting piece can be tightened. A cylinder 3 is also arranged on the bracket, one end of the cylinder 3 is fixed on the bracket, and the other end is connected with the cutting device. When the cylinder b3 is inflated, the cutting device will slowly press down to cut. The cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com