Wire pole traction steel cable fastening device for electric power transmission and installing method of wire pole traction steel cable fastening device

A technology for power transmission and fastening device, applied in the direction of textile cables, transmission elements or pulley ropes or cables, belts/chains/gears, etc. The effect of grip, productivity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

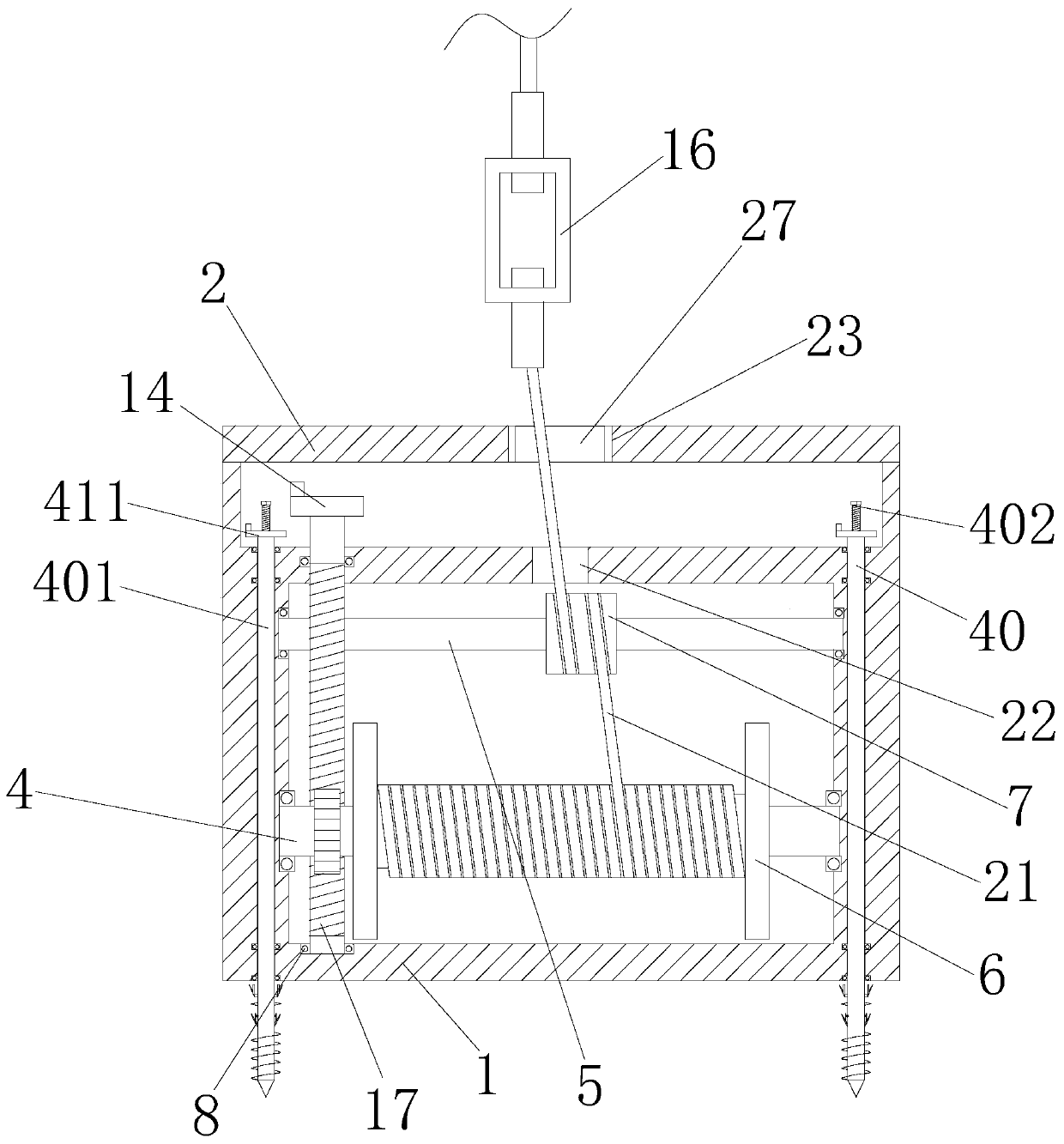

Image

Examples

Embodiment 1

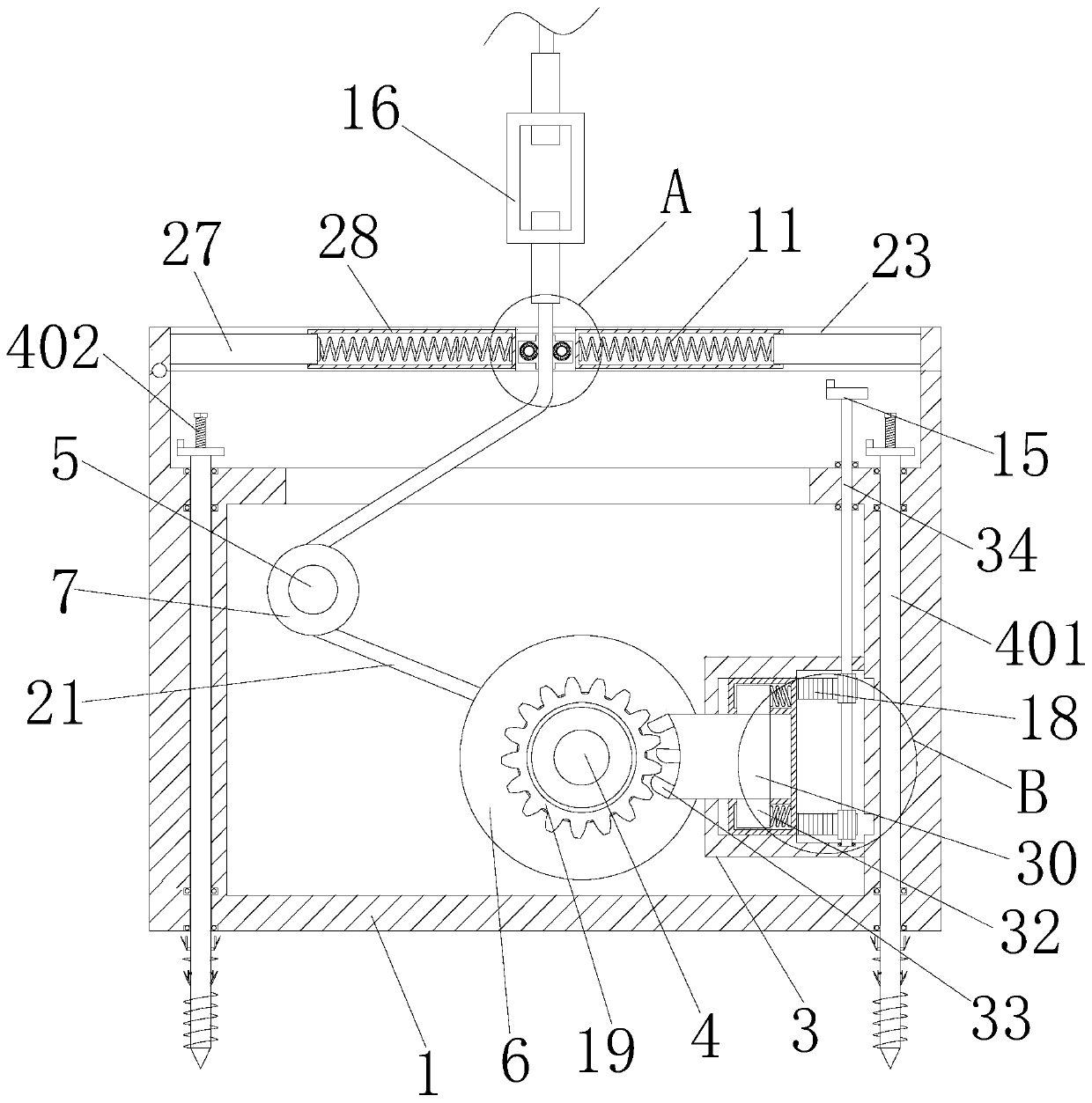

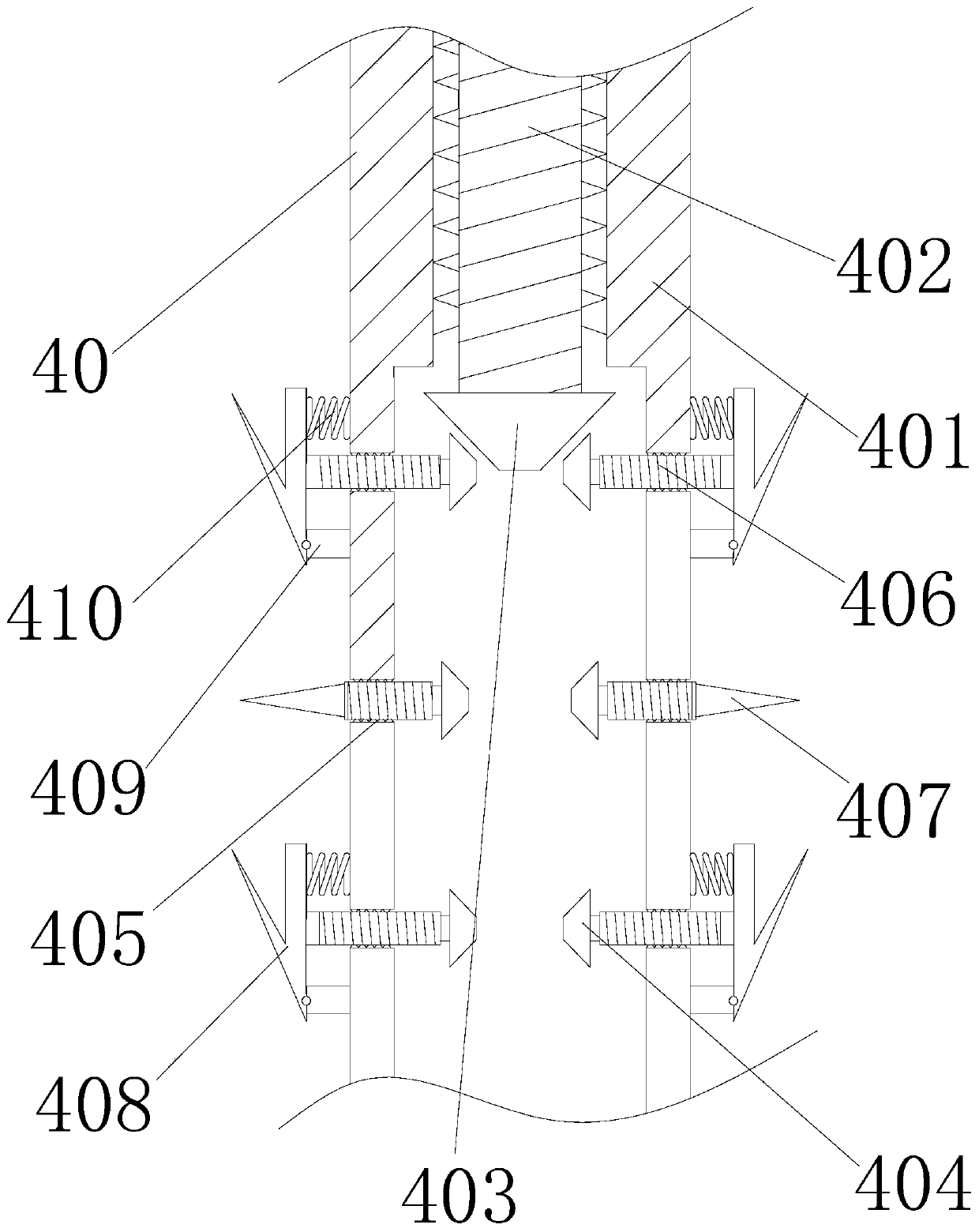

[0032] The present invention also provides: a method for installing a utility pole traction steel cable fastening device for electric power transmission, comprising the following steps:

[0033] S1. Place the shell in the excavated foundation pit, open the protective cover and turn the third hand wheel, so that the drill bit at the bottom of the support rod can drill downward through the spiral part, and use the tool to continuously rotate the screw thread after descending to the target height Rod, so that the threaded rod drops to the bottom in the support rod, and the threaded rod will rotate downward through the thread inside the support rod. The connecting rod rotates toward the outside of the support rod in the threaded hole, and the barbs are opened outward by rotating the connecting rod;

[0034] S2. Turn the second hand wheel to rotate the second gear connected to the outer wall. When the second gear rotates, it drives the rack to move 38cm to the right, and the rack d...

Embodiment 2

[0038] The present invention also provides: a method for installing a utility pole traction steel cable fastening device for electric power transmission, comprising the following steps:

[0039] S1. Place the shell in the excavated foundation pit, open the protective cover and turn the third hand wheel, so that the drill bit at the bottom of the support rod can drill downward through the spiral part, and use the tool to continuously rotate the screw thread after descending to the target height Rod, so that the threaded rod drops to the bottom in the support rod, and the threaded rod will rotate downward through the thread inside the support rod. The drill rod rotates in the threaded hole to the outside of the support rod, and drills outward by rotating the drill rod;

[0040] S2. Turn the second handwheel to rotate the second gear connected to the outer wall. When the second gear rotates, it drives the rack to move 45cm to the right, and the rack drives the fixed seat to move ...

Embodiment 3

[0044] The present invention also provides: a method for installing a utility pole traction steel cable fastening device for electric power transmission, comprising the following steps:

[0045] S1. Place the shell in the excavated foundation pit, open the protective cover and turn the third hand wheel, so that the drill bit at the bottom of the support rod can drill downward through the spiral part, and use the tool to continuously rotate the screw thread after descending to the target height Rod, so that the threaded rod drops to the bottom in the support rod, and the threaded rod will rotate downward through the thread inside the support rod. The connecting rod rotates toward the outside of the support rod in the threaded hole, and the barbs are opened outward by rotating the connecting rod;

[0046] S2. Turn the second hand wheel to rotate the second gear connected to the outer wall. When the second gear rotates, it drives the rack to move 49cm to the right, and the rack d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com