Diesel engine cam shaft pressure-reducing mechanism

A decompression mechanism and camshaft technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of heavy engineering and high design costs, and achieve the effects of firm and reliable connection, simple processing, and lower critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

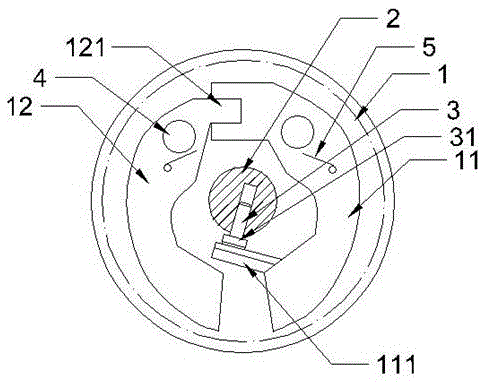

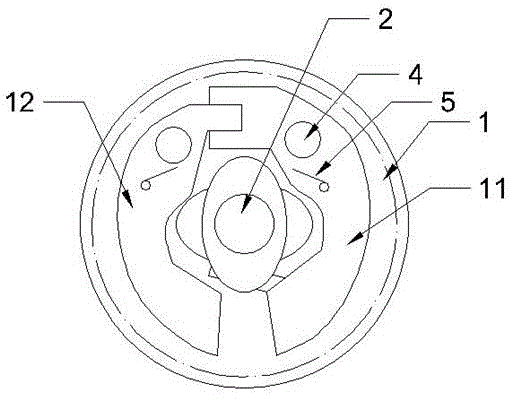

[0015] The reference numerals in the accompanying drawings include: driven gear 1, first centrifugal arm 11, execution block 111, second centrifugal arm 12, bump 121, camshaft 2, decompression pin 3, cap head 31, rivet 4 , torsion spring 5.

[0016] The embodiment is basically as attached figure 1 with figure 2 Shown: the diesel engine camshaft decompression mechanism in this program includes a camshaft 2, a driven gear 1 and several cams installed on the camshaft 2, and the driven gear 1 is rotatably connected with the first centrifugal arm 11 and The second centrifugal arm 12 is also equipped with a torsion spring 5 .

[0017] The upper end of the first centrifugal arm 11 is processed with an opening, and the second centrifugal arm 12 is processed with a protrusion 121 inserted into the opening so that the first centrifugal arm 11 and the second centrifugal arm 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com