Low-nickel-zinc cupronickel shielding case and manufacturing method thereof

A manufacturing method and shielding cover technology, applied in local shielding, magnetic field/electric field shielding, electrical components, etc., can solve the problems of high temperature resistance and yellowing of low nickel white copper, improve solderability, reduce annealing temperature, and improve performance uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

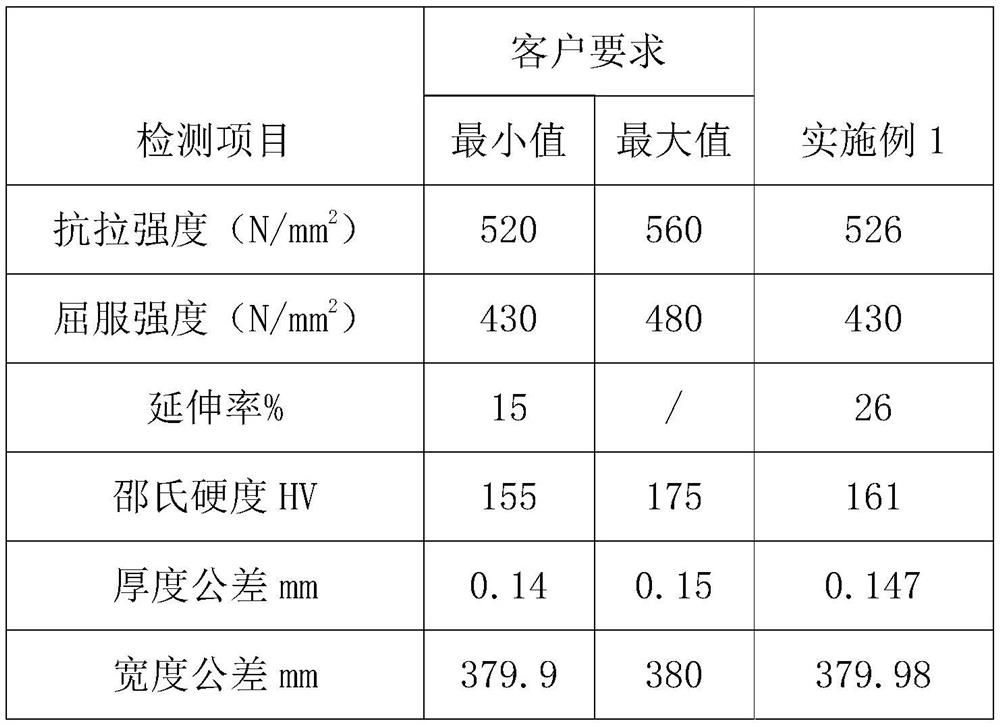

Embodiment 1

[0070] A low-nickel-zinc-nickel-nickel shielding cover, comprising the following components in mass percentage:

[0071] Cu 59.35%, Ni 11.85%, Fe 0.15%, Pb 0.0025%, Mn: 0.20%, Sn 0.0010%, Zn balance.

[0072] The manufacturing method of the above-mentioned low-nickel-zinc-nickel-nickel shielding cover comprises the following steps:

[0073] 1) Ingredients: Recycled material, cupronickel corner material, zinc supplement block or bright copper wire, etc. are weighed and put into the melting furnace;

[0074] 2) Smelting: The weighed metals are mixed and melted into a melt, and the electrolytic manganese is added to the charcoal in the furnace, and the fine electrolytic manganese that is not completely melted on the charcoal is pounded into the copper liquid with a slag scoop.

[0075] In order to ensure the quality of the melt, the raw materials and covering agents used must be dry. After the preparation of the melt is completed, the composition is adjusted according to the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com