Working table floating guide rail device

A technology of guide rail device and workbench, which is applied in the direction of grinding frame, grinding bed, grinding slide plate, etc. It can solve the problems of affecting the processing accuracy and the heat deformation of double V guide rails cannot be released, and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

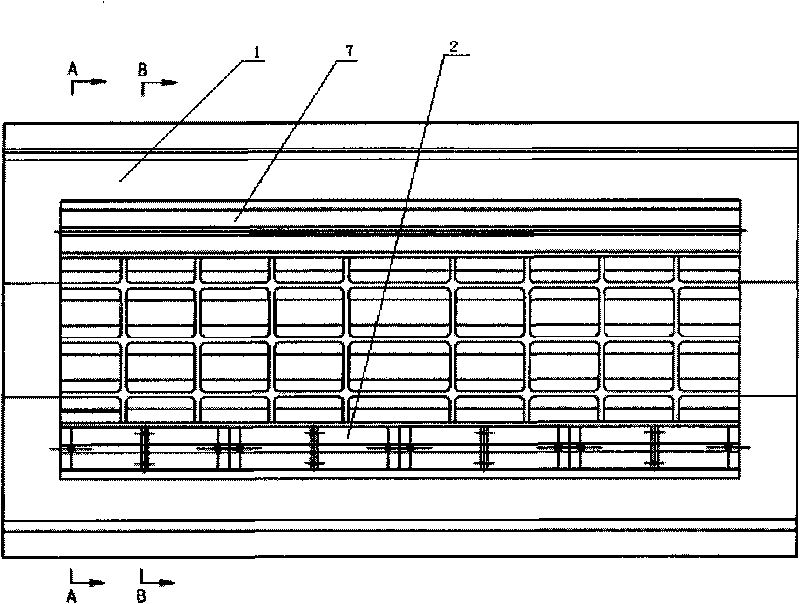

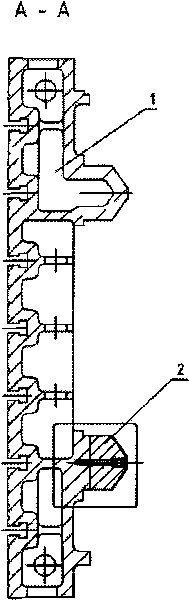

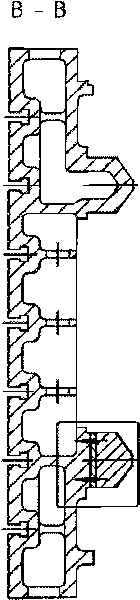

[0013] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, there is a workbench 1, on which a left guide rail 7 is horizontally fixed, and a right guide rail is installed parallel to one side of the left guide rail 7. Connected together, the screw 3 cannot be tightened, and the anti-loosening screw 4 is installed at the bottom of the screw 3 to prevent the screw 3 from falling off. A guide key 5 is installed between the workbench 1 and each section of floating guide rail 2, and the guide key 5 uses a screw 6 It is fixed on the workbench 1, so that the floating guide rail 2 can move freely laterally in the direction of the guide key 5. The thermal deformation of the worktable due to heating during the working process can be freely released to ensure the grinding accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com