Hydraulic system of full-automatic polypropylene forming machine

A hydraulic system and fully automatic technology, applied in the field of polypropylene automatic molding machines, can solve problems such as insufficient locking force and affecting molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

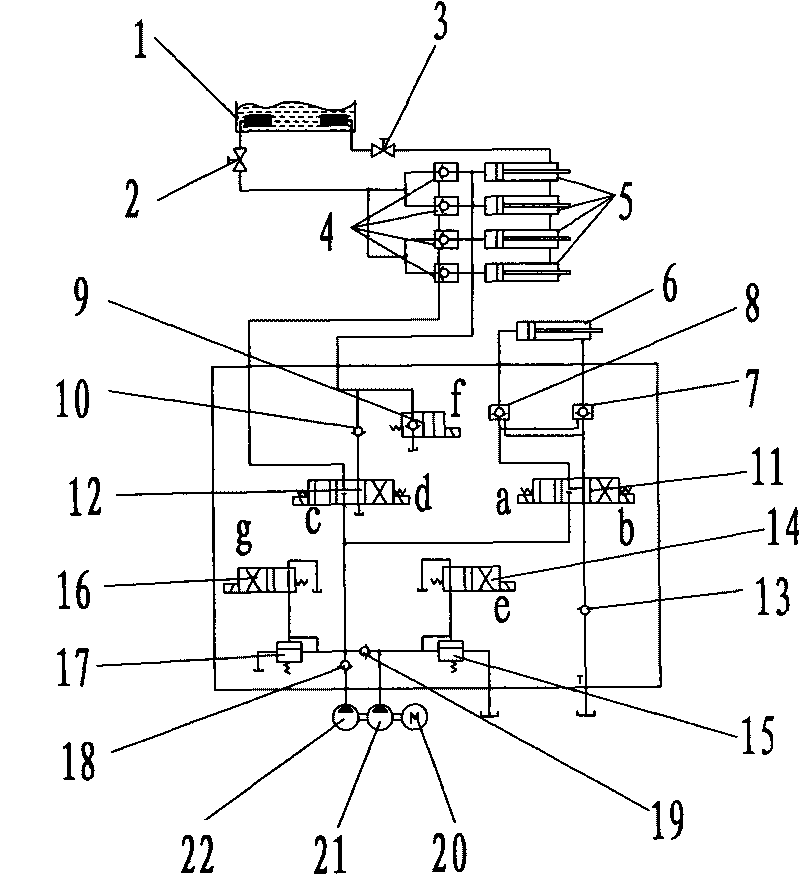

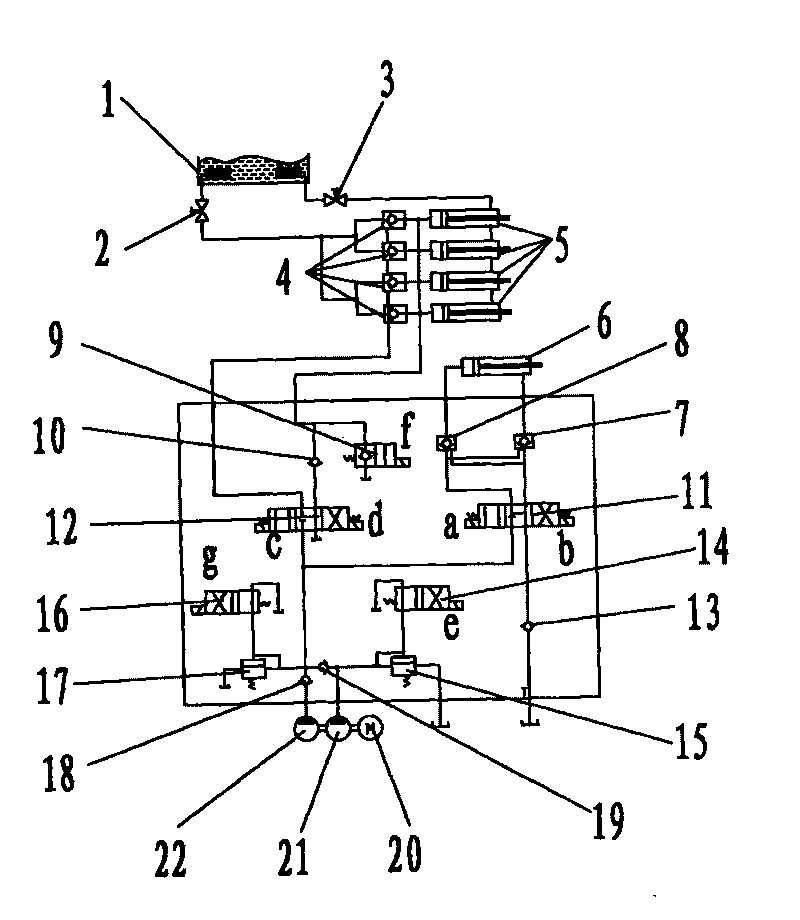

[0009] See attached figure 1 , the hydraulic system of the polypropylene automatic molding machine of the present invention comprises 1, fuel tank; 2, valve 1; 3, valve 2; 4, filling valve; 5, oil cylinder; 6, oil cylinder 2; 7, check valve; 8 , check valve; 9, pressure relief valve; 10, one-way valve; 11, electromagnetic reversing valve; 12, electromagnetic reversing valve; 13, one-way valve; 14, electromagnetic reversing valve; 15, reverse flow valve; 16 1. Electromagnetic reversing valve; 17. Reverse flow valve; 18. One-way valve; 19. One-way valve; 20. Electric motor; 21. Oil pump; 22. Oil pump. PLC controller (not shown in the figure), coil a, b, c, e, g of electromagnetic valve, oil cylinder 5, oil cylinder 6, oil pump 21, oil pump 22; The whole system controls electromagnetic valve through PLC controller, coil a, When c, e, and g are energized, they will move forward quickly; when coils b, c, e, and g are energized, they will quickly retreat; when coils a, c, and g are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com