Friction testing device

A test device and skateboard technology, which is applied in the field of physical science, can solve problems such as experiments that cannot be done at small angles, and achieve the effects of compact structure, reduced error, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

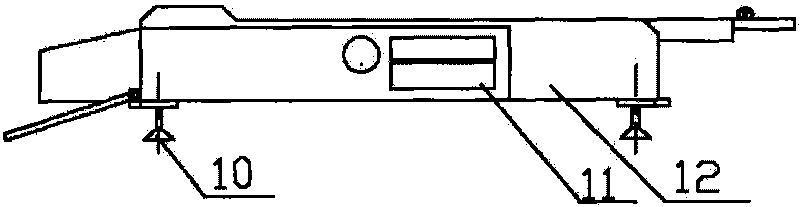

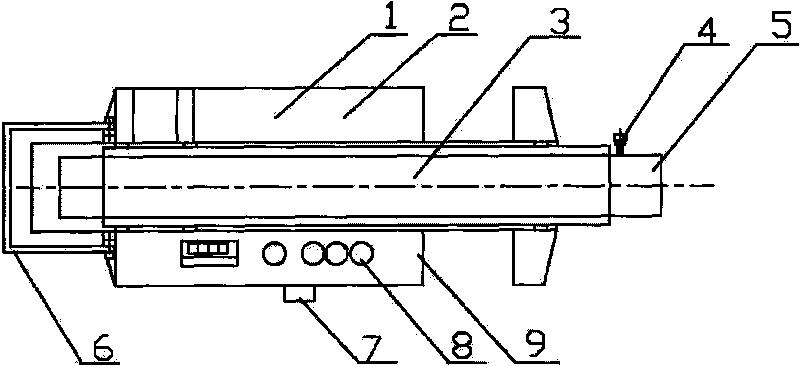

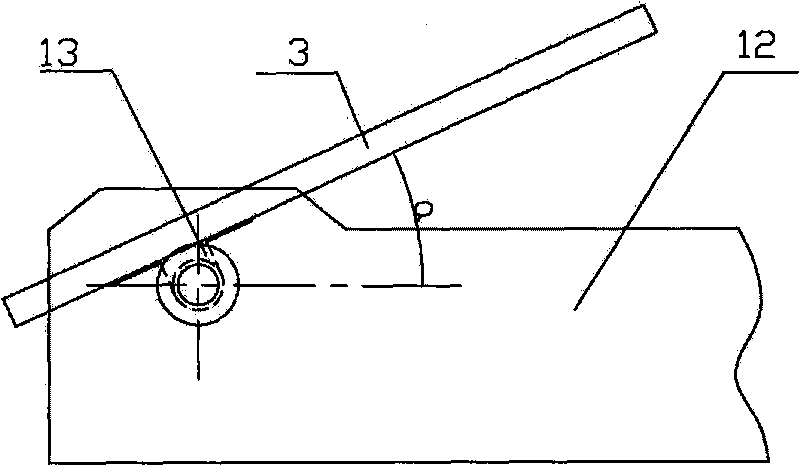

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] The friction test device of the present invention is mainly to carry out the following experiments to better understand the essence of tribology:

[0028] (1) Measure the coefficient of static friction of different materials by changing the inclination angle;

[0029] (2) Measure the kinetic friction coefficient of different materials by measuring the time interval between two points;

[0030] (3) When the height of the slider is large, it can demonstrate the overturning and sliding of the slider under different loads;

[0031] (4) It can demonstrate the pure rolling and rolling and sliding motion of the wheel on the inclined surface.

[0032] In order to improve the test accuracy, the present invention mainly includes the following two aspects: one is to effectively adjust the inclination angle of the skateboard; the other is to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com