Air-cooled heat dissipation structure of high-power converter device

A technology of heat dissipation structure and converter, which is applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

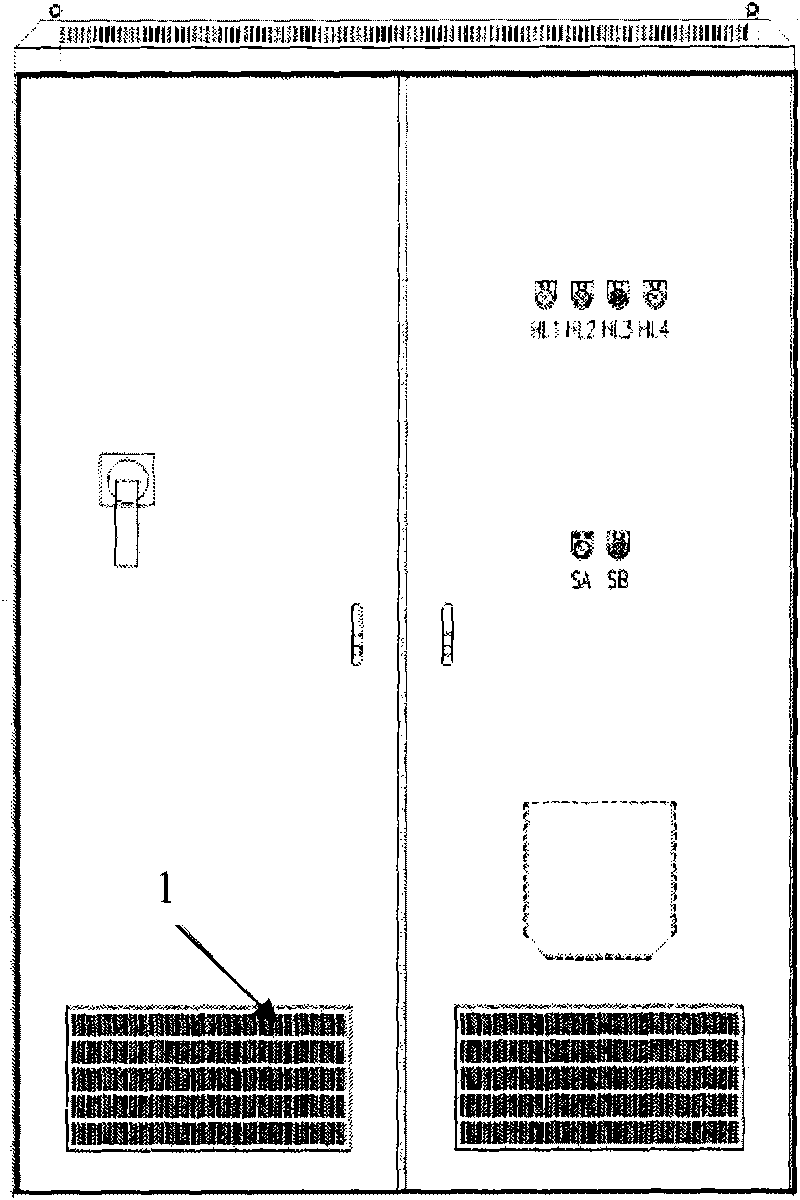

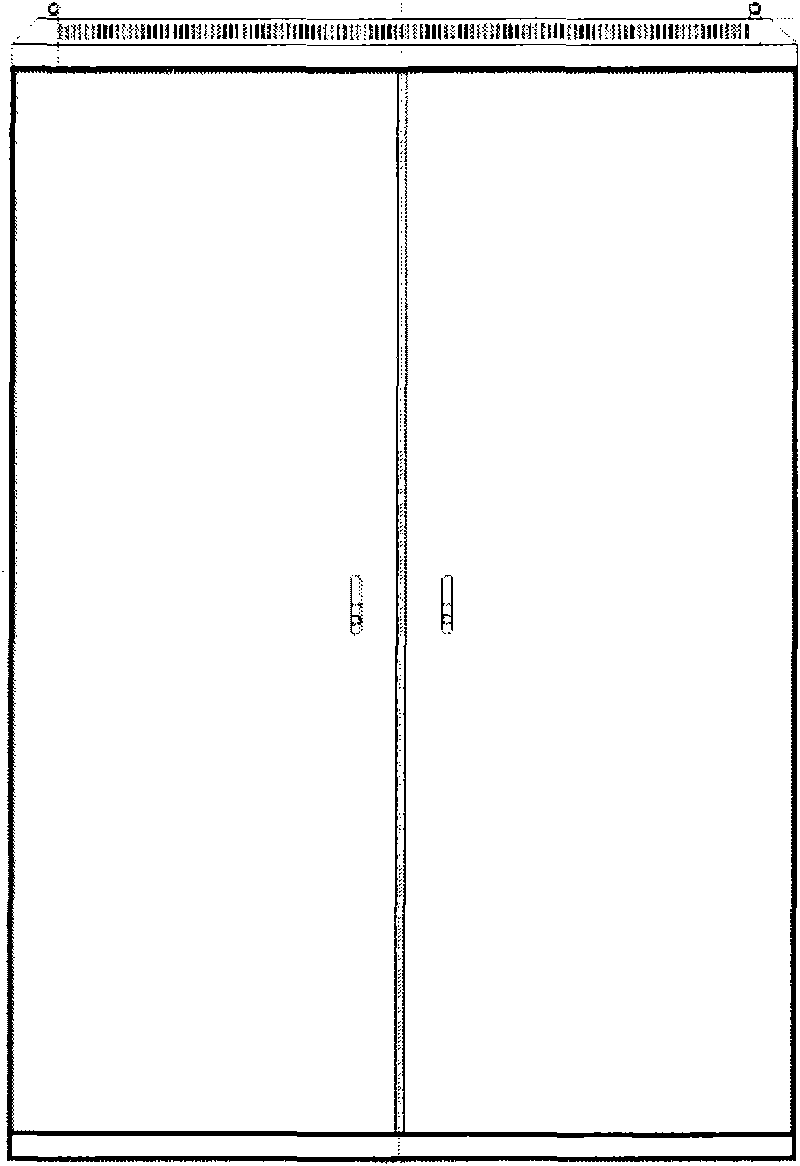

[0026] Embodiment: An air-cooled heat dissipation structure device for a high-power converter

[0027] An air-cooled and heat-dissipating structure for a high-power converter device. A vertical partition is provided in the cabinet cavity of the high-power converter device, and the vertical partition separates the inner space of the cavity into a first cavity and a second cavity. Cavities; the tops of the first cavity and the second cavity are respectively provided with air outlets, and the bottoms of the first cavity and the second cavity are respectively provided with air inlets, thereby forming the first and second heat dissipation air ducts. There is a distance between the bottom edge of the vertical partition and the bottom surface of the cabinet, so as to form a connected space at the bottom of the cabinet cavity; a common air inlet is provided on the side of the connected space, and the shared air inlet is connected to the first cavity and the second cavity. The air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com