Method for producing an electronic component and electronic component

A technology for electronic components and components, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of high cost and high-cost cleaning process, and achieve the effect of simple insulating layer and avoiding weak links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

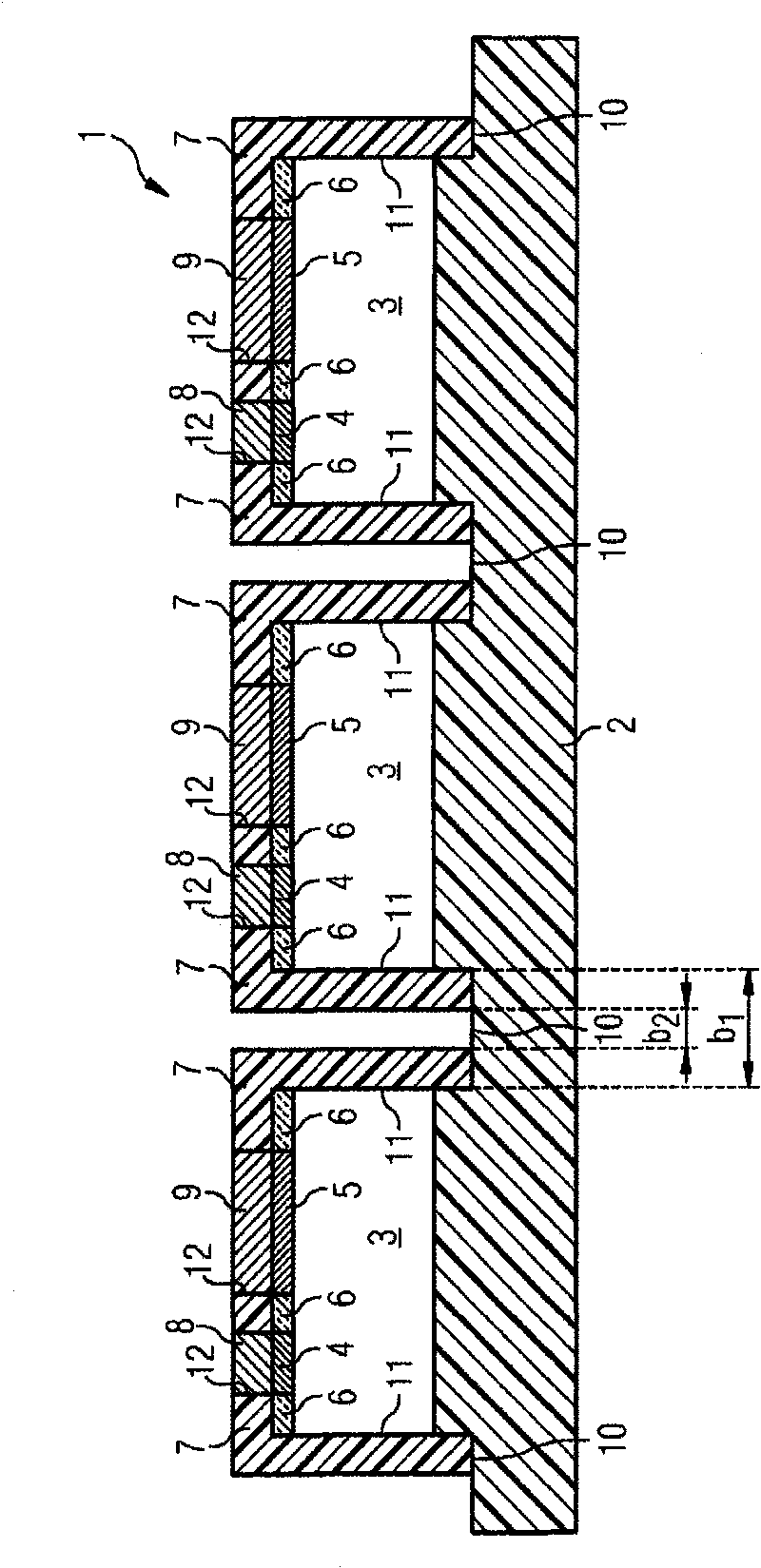

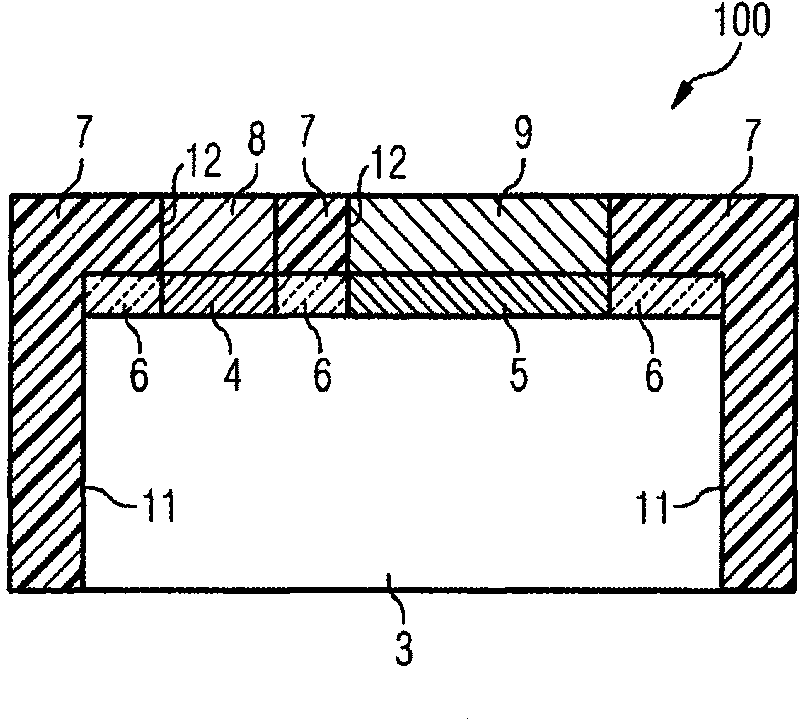

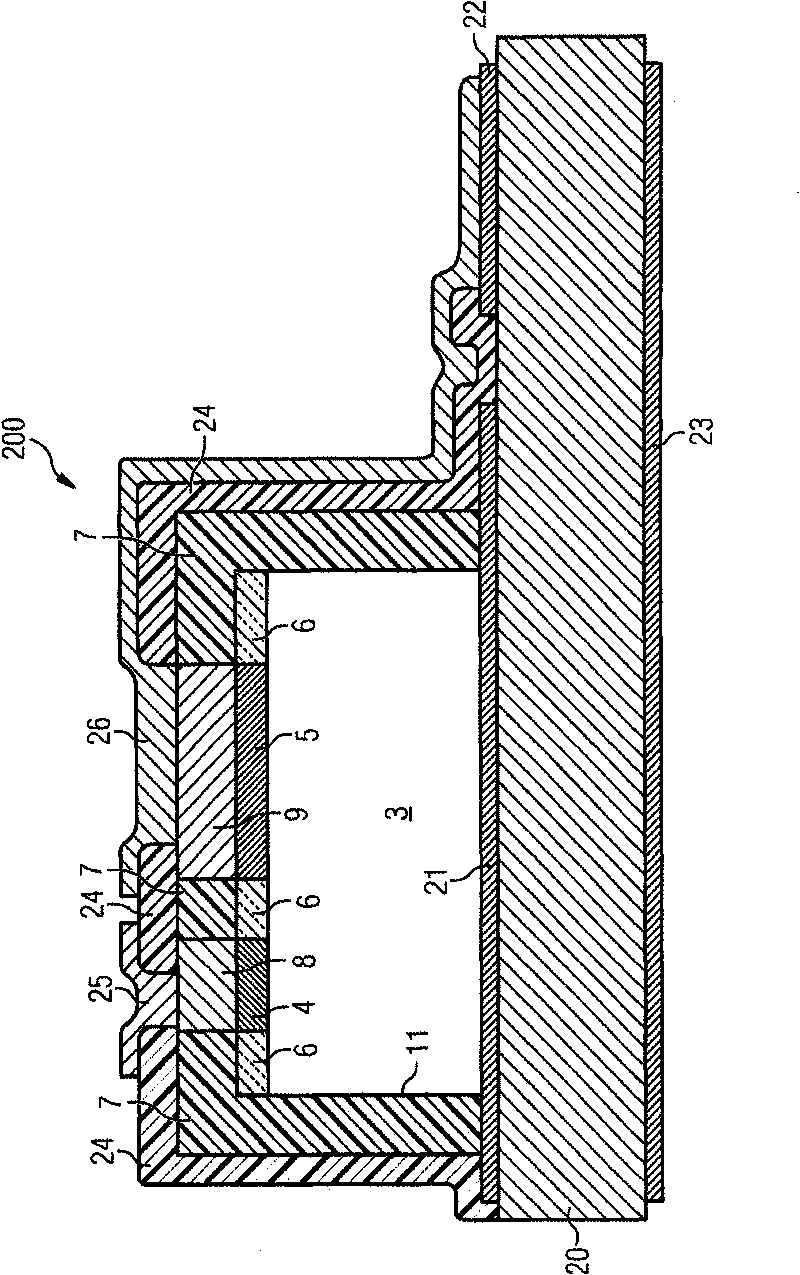

[0035] figure 1 A schematic illustration shows a cross-section of, for example, three chips arranged side by side in composite wafer 1 . In this case, the chip 3 is arranged on a carrier 2, for example a serrated film equipped with an adhesive surface. In this case, the connection of the carrier 2 to the wafer takes place before the chip 3 is separated from the composite wafer 1 .

[0036] Each of the chips 3 has, for example, two chip contact areas 4 , 5 on the main side facing away from the carrier 2 . These main sides are provided with a passivation layer 6 as usual when processing wafers. In a known manner, the chip contact areas 4 , 5 and the surface of the passivation layer 6 facing away from the chip 3 lie approximately in one plane.

[0037] As a preparation for applying the insulating layer 7 to the surfaces of the chips 3 , the chips 3 are optionally (adhered to the carrier 2 ) separated from one another. The width of each corresponding dividing line between two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com