Dynamic impact loading test bed and test system thereof

A loading test and dynamic technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of poor safety performance and bulky equipment, and achieve the effect of low noise pollution, high energy conversion rate, and easy repeated test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings. For those skilled in the art, the above objects, features and advantages of the present invention will be apparent from the detailed description of the present invention.

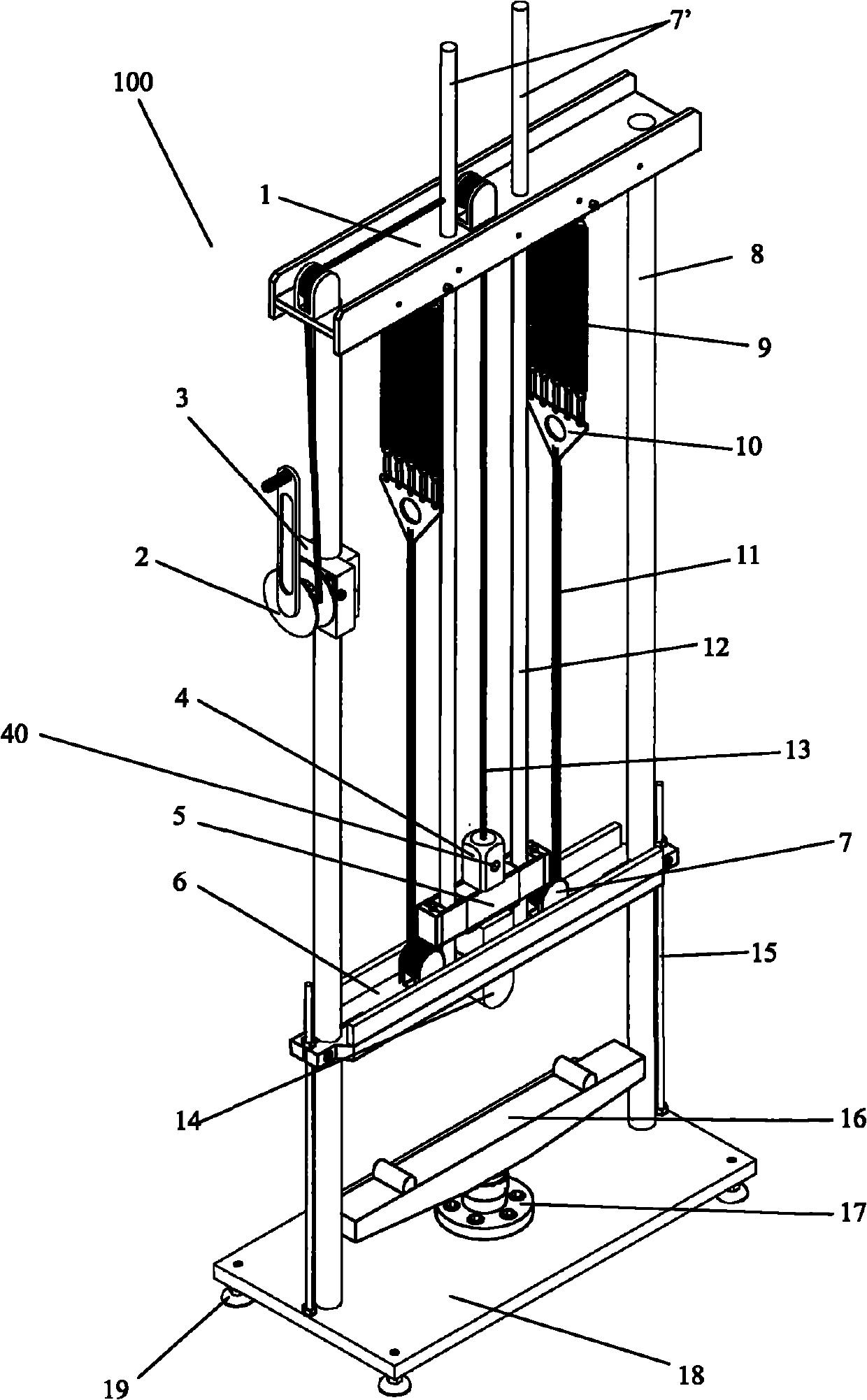

[0027] refer to figure 1 , is a schematic diagram of the overall structure of a dynamic impact loading test bench according to a specific embodiment of the present invention. As shown in the figure, the dynamic impact loading test bench 100 includes an impact unit, a tension spring unit, a lifting unit and a specimen carrying platform carried on a fixed frame.

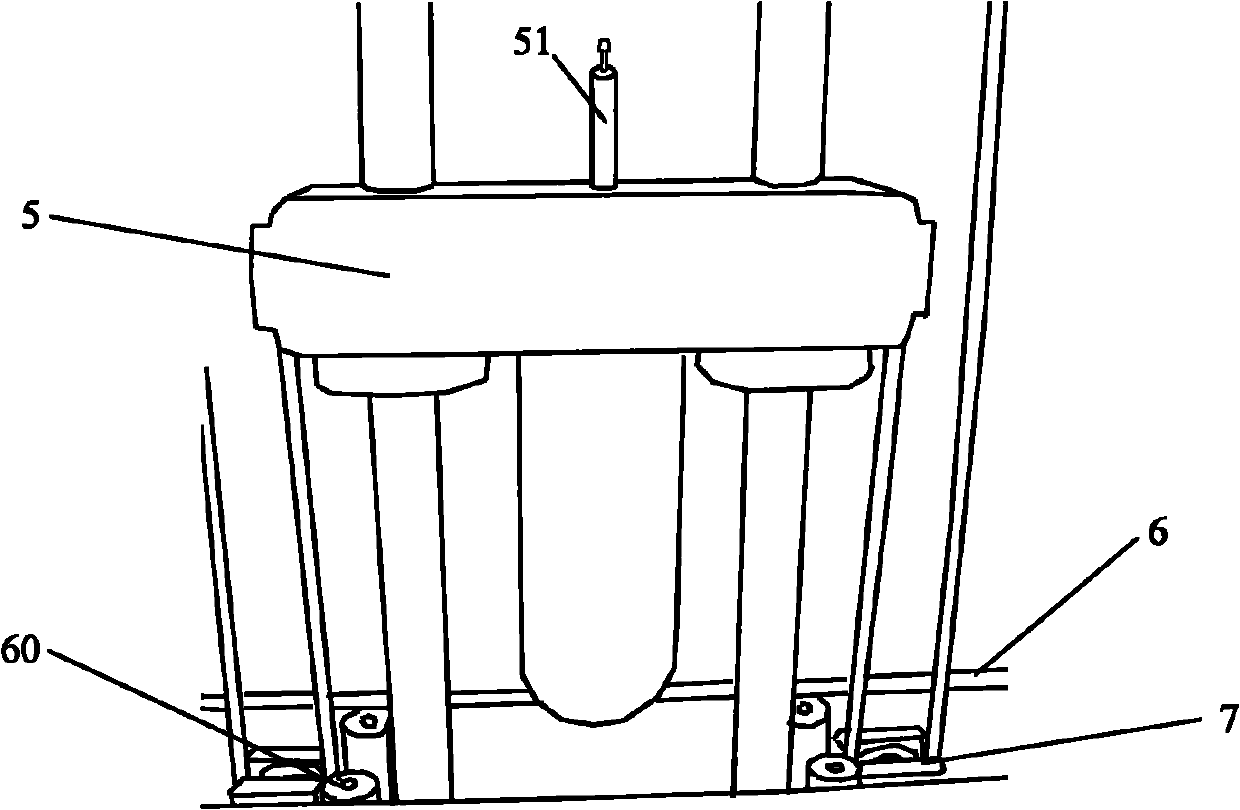

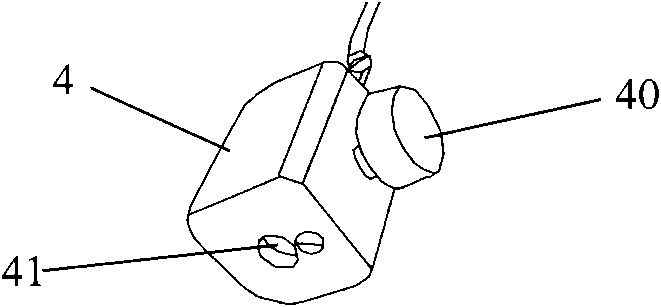

[0028] exist figure 1 Among them, the impact unit is a T-shaped heavy hammer, which includes a hammer body 5 forming a body and a hammer head 14 forming a striking part. The hammer body 5 is coated with a nylon sleeve, which is used to reduce the friction with the "I"-shaped adjustment horizontal plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com