Tunnel type shipboard aircraft catapult capable of using multiple types of energy

A carrier-based aircraft and catapult technology, which is applied in the launch/tow transmission device and other directions, can solve the problems of difficult processing, large friction resistance of cylinder pistons, and large space occupation, so as to improve energy conversion efficiency, reduce friction resistance, improve The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

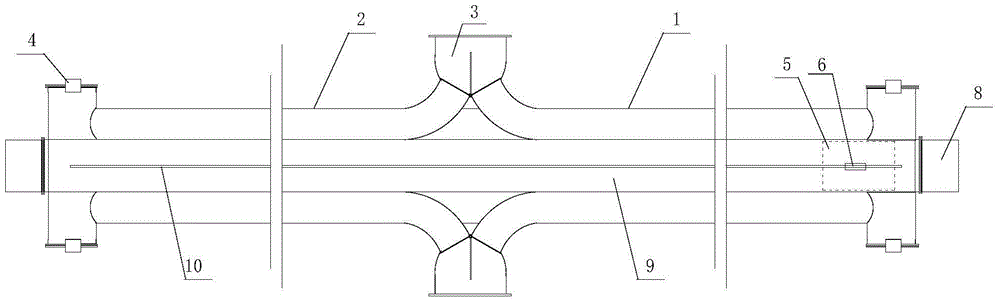

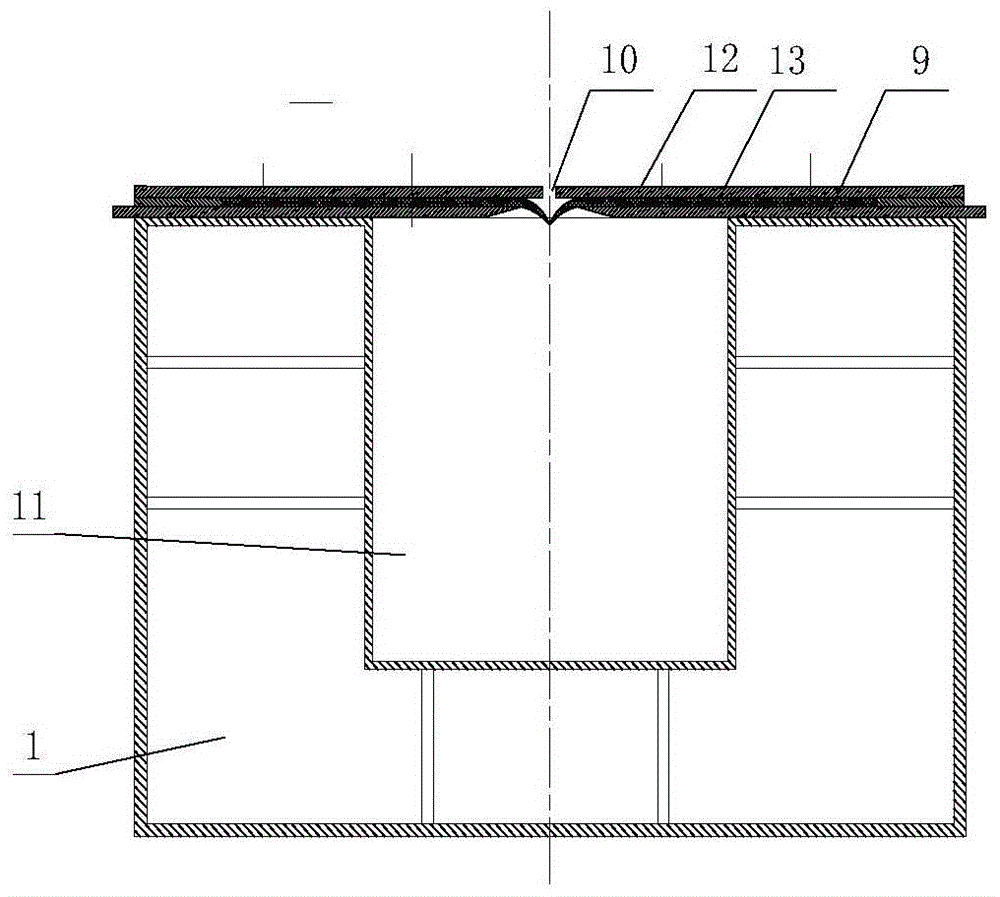

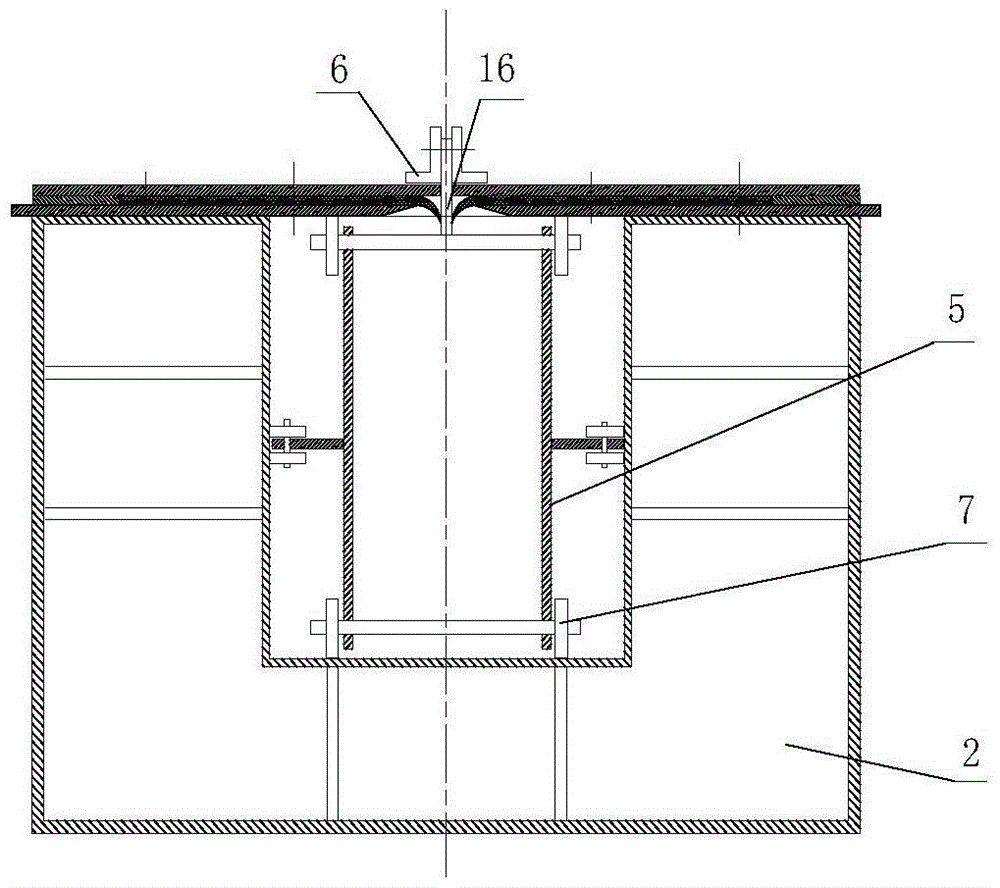

Method used

Image

Examples

Embodiment 1

[0036] The right end of the work tunnel is set as the ejector point, the left end is the ejection end point, and the aviation turbofan engine is used as the high-energy medium supply equipment. The specific ejection steps are as follows:

[0037] When preparing to eject the carrier-based aircraft, the medium discharge valves at both ends of the work tunnel are opened, the controller assembly starts the aviation turbofan engine to run at high speed and is in the state of energy storage, and the high-energy medium flow at the tail nozzle of the aviation turbofan engine enters the power supply through the ejection medium delivery pipe. At the starting point of the tunnel, the airflow from the turbojet engine not only has high flow and high wind pressure, but also has a high temperature of over 2000°C. The high-temperature airflow heats the ejection medium delivery pipe to form a heat storage boiler. The discharge valve is empty. At this time, the tunnel trolley is located at the s...

Embodiment 2

[0042] The right end of the work tunnel is set as the ejector point, the left end is the ejection end point, and the high-pressure steam storage tank is used as the high-energy medium supply equipment; the high-energy medium is steam or air; the specific ejection steps are as follows:

[0043] When preparing to eject the carrier-based aircraft, the high-pressure steam storage tank is connected to the starting point of the power tunnel through the reversing valve and the ejection medium delivery pipe. The tow bar of the landing gear is connected with the shuttle hook, and the carrier aircraft is in the preparation stage for takeoff;

[0044] When the flight tower issues the launch command of the carrier-based aircraft, the controller assembly controls to close the medium discharge valve at the starting point of the power tunnel, open the medium discharge valve at the end of the power tunnel, and the high-energy medium enters the starting point of the power tunnel through the eje...

Embodiment 3

[0048] The right end of the working tunnel is set as the catapult point, and the left end is the ejection end point, and the high-pressure pump group and the air compressor are used as the high-energy medium supply equipment. The high-energy medium is liquid water or a liquid-gas mixture formed by pressing high-pressure air into liquid water. The purpose is to increase the compressibility of the liquid. The specific ejection steps are as follows:

[0049] When preparing to eject the carrier-based aircraft, the high-pressure pump set is connected to the starting point of the power tunnel through the reversing valve and the ejection medium delivery pipeline, and the medium discharge valve on the starting point of the power tunnel is opened, and the high-energy medium enters the starting point of the power tunnel through the ejection medium delivery pipeline, and the power is discharged from the starting point of the power tunnel. The medium discharge valve at the starting point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com