Efficient and energy-saving alkaline dry battery

A high-efficiency, energy-saving, dry battery technology, applied in the direction of alkaline storage batteries, secondary batteries, circuits, etc., can solve the problems of carbon nanomaterials production and mass production, no use of carbon nanomaterials, less research and development, etc., to achieve novel structure, manufacturing The effect of simple process and large electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

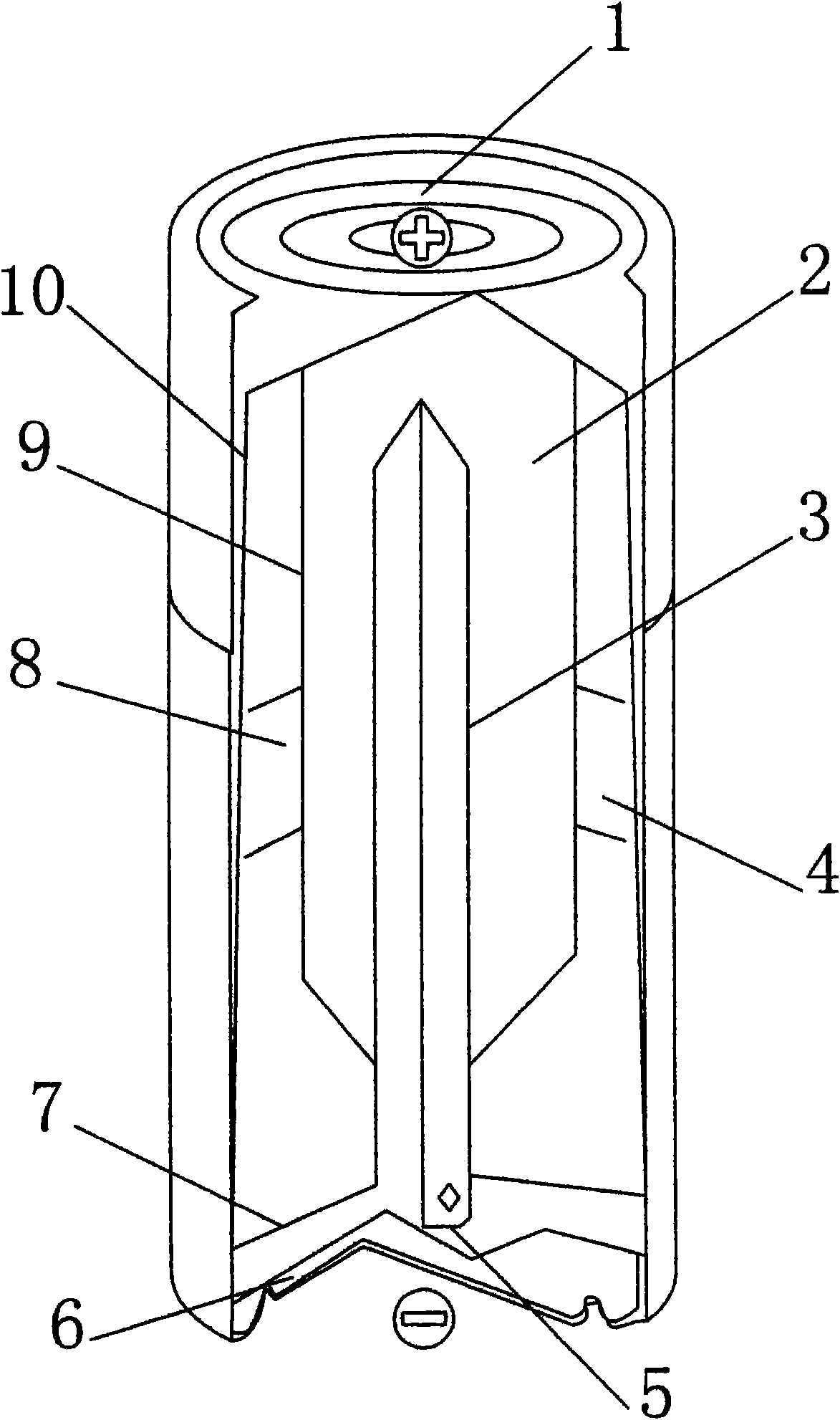

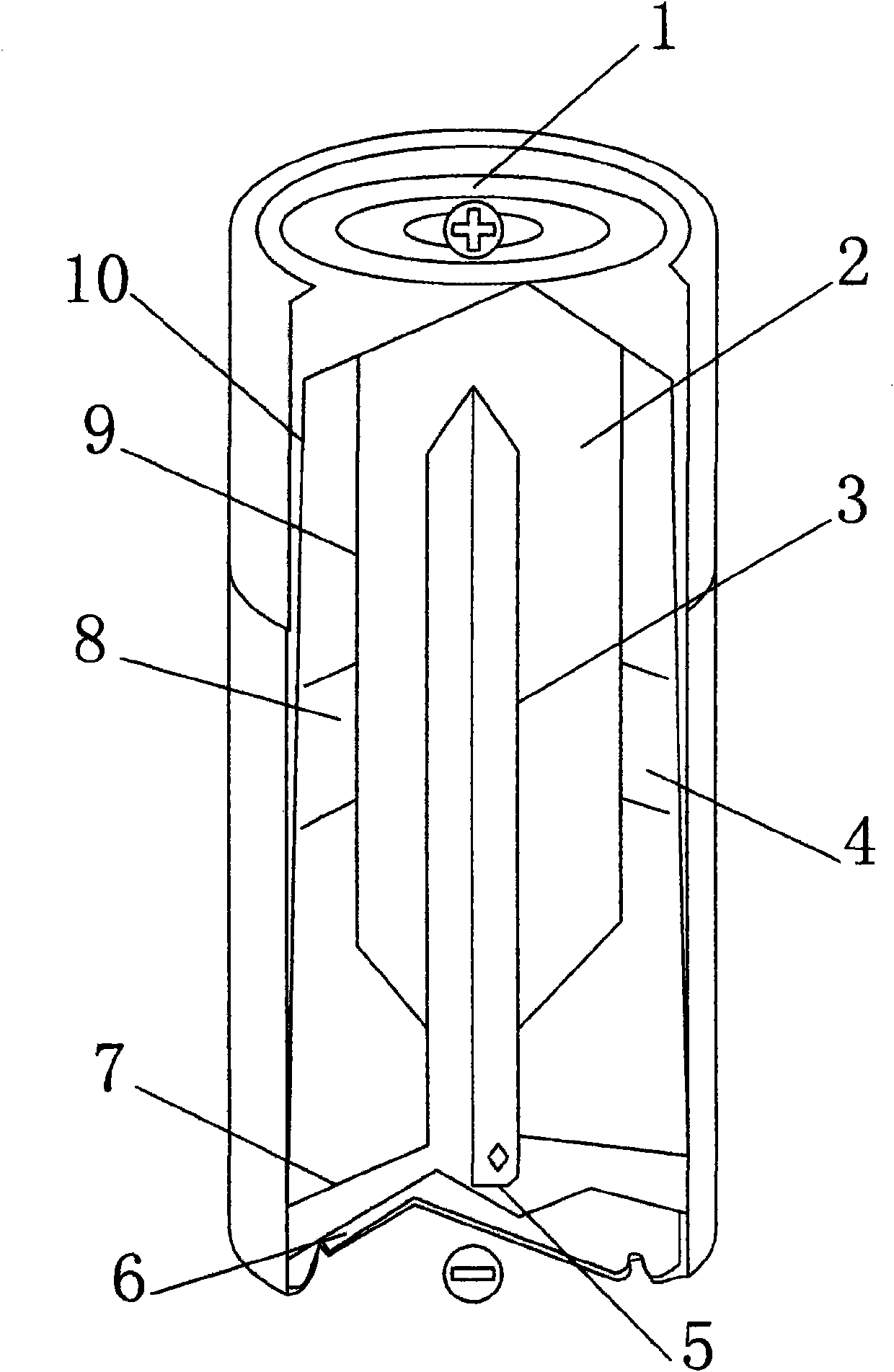

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0013] Production process of the present invention:

[0014] 1. Carbon nano battery electrolyte and electrolyte synthesis material

[0015] 1. Add 1%, 20%, 30% or 40% carbon nano powder / tube material synthesis in the manufacturing process of battery "positive and negative electrode electrolyte".

[0016] 2. Coating or implanting 1%, 20%, 30% or 40% carbon nano powder / tube material synthesis in the manufacturing process of battery "positive and negative electrolyte".

[0017] 2. Synthetic materials such as carbon nanometer battery separator, steel shell, copper rod, steel jacket, etc.

[0018] 1. Add 1%, 20%, 30% or 40% carbon nano powder / tube material synthesis in the manufacturing process of battery "diaphragm, steel shell, copper rod, steel jacket".

[0019] 2. Coating or implanting 1%, 20%, 30% or 40% carbon nano powder / tube material synthesis in the manuf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap