Granule coated with urethane resin

一种聚氨酯树脂、颗粒的技术,应用在肥料形式、应用、运输和包装等方向,能够解决难以控制洗脱等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

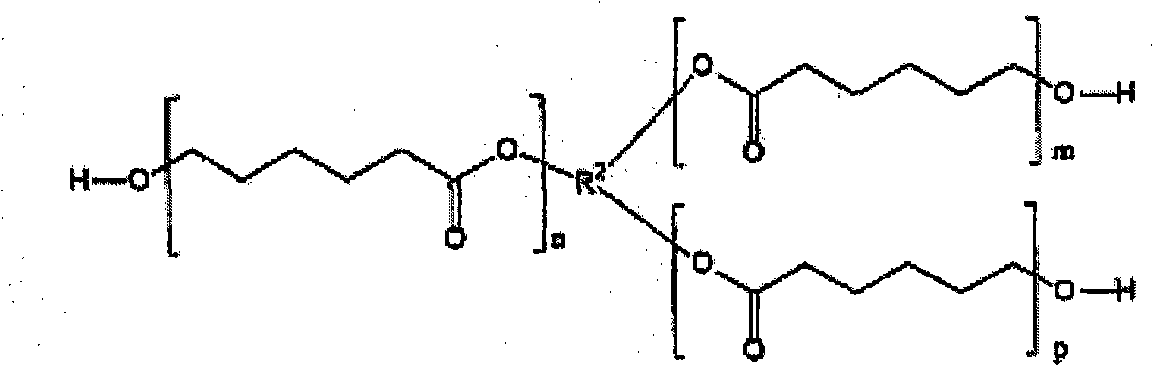

Method used

Image

Examples

Embodiment

[0088] The present invention is explained in more detail below by the production examples and test examples mentioned later, but the present invention is not limited to the examples only.

[0089] Reference example (production of polyurethane resin film)

[0090] The polyurethane resin film is manufactured under the following conditions:

[0091] Mix polyester polyol and alkanol as described in Table 1 and Table 2 with 2,4,6-tris(dimethylaminomethyl)phenol (catalyst) uniformly at about 50°C, then add aromatic polyol Isocyanate, mixed quickly and drawn into thin sheets (for degradation testing) using a plater set at a thickness of about 125 μm. The drawn resin was left standing still at 70° C. for 3 hours to cause hardening to obtain polyurethane resin films (A) to (F) and (a).

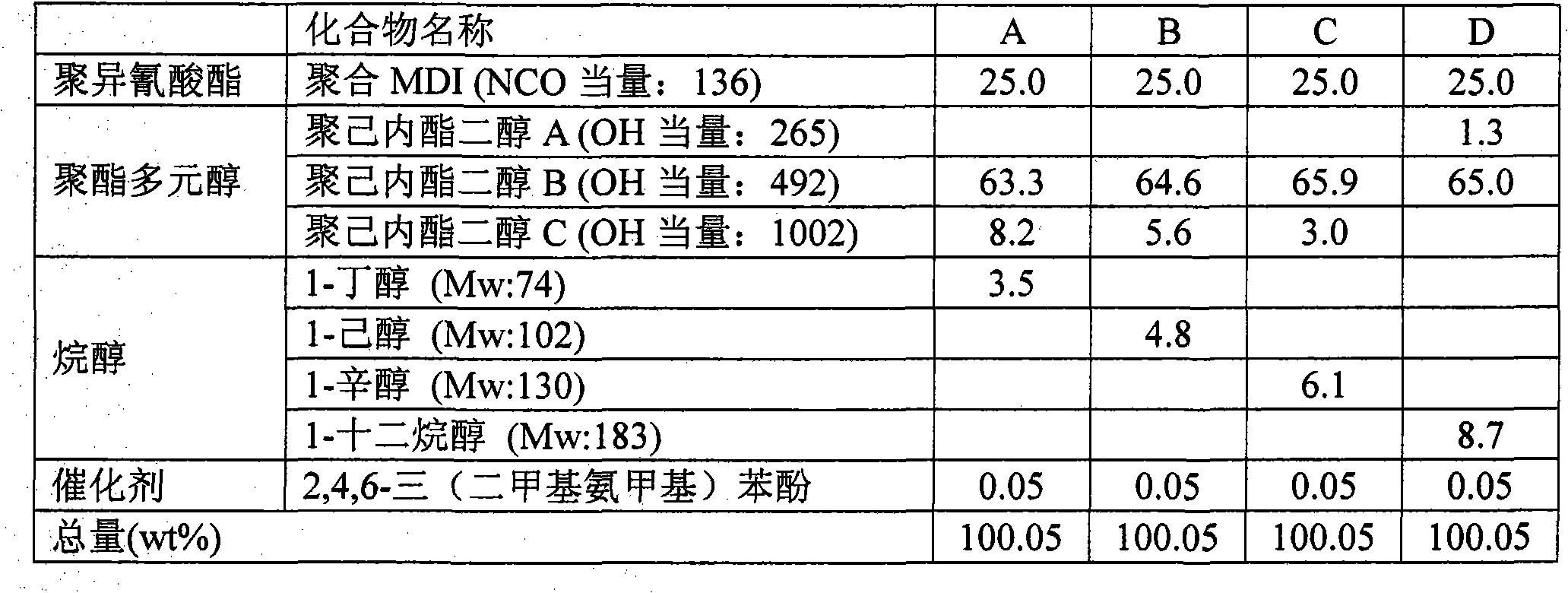

[0092] Table 1

[0093]

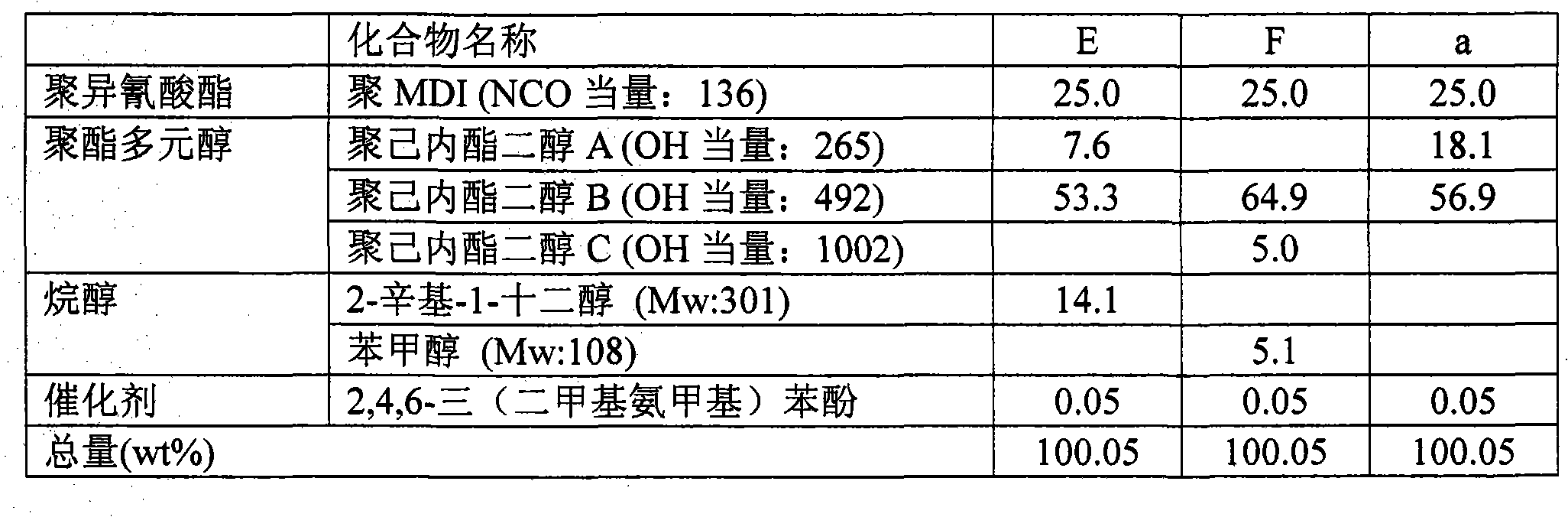

[0094] Table 2

[0095]

[0096] In Tables 1 and 2 above:

[0097] Poly MDI (Sumidur 44V-10, manufactured by Sumika Beyer Urethane Co., Ltd.);

[0098] Polycaprola...

Embodiment 1

[0116] Under the conditions described later, the coated granular fertilizer was prepared by coating granular urea (large grained urea with a particle size of about 3 mm and a particle number of 60 particles per gram) with the polyurethane resin raw material composition (C) described in Table 1. And produced.

[0117] In a rotating tank, 1000 parts by weight of granular urea was tumbled, and the granular urea was heated to about 70° C. by hot air. Next, 15 parts by weight of liquid paraffin was added, and rolling was continued for 10 minutes. 5 parts by weight of unhardened polyurethane resin having the formulation described in Table 1 was further added. Unhardened polyurethane resin is prepared by uniformly mixing polyester polyol, alkanol and 2,4,6-tris(dimethylaminomethyl)phenol (catalyst) at about 70°C, and then adding aromatic polyisocyanate and prepared by mixing rapidly. After the addition of the unhardened urethane resin, the mixture was kept tumbling for 3 more minu...

Embodiment 2

[0119]8 parts by weight of N-(1,1,3-trimethyl-2-oxa-4-dihydroindenyl)-5-chloro-1,3-dimethylpyrazole-4-carboxamide, 1.6 Parts by weight of hydrous silica (TOKUSEAL GU-N, manufactured by Tokuyama Soda Co., Ltd.) and 8 parts by weight of bentonite (BENTONITE FUJI, manufactured by Hojun Kogyo Co., Ltd.) were thoroughly mixed and then pulverized by a jet mill. 17.6 parts by weight of the pulverized material obtained above, 4.5 parts by weight containing 3.15 parts by weight of [(E)-1-(2-chloro-1,3-thiazol-4-ylmethyl)-3-methyl-2-nitrate guanidine] and 1.35 parts by weight of a ground mixture of clay (SHOKOSAN Clay S, manufactured by Shokosan Kogyosho Co., Ltd.), 3 parts by weight containing 2.5 parts by weight of polyvinyl alcohol (GOHSENOL GL-05, manufactured by Nippon Synthetic Chemical Industry Co., Ltd.) and A mixture of 0.5 parts by weight of PVA 217S (manufactured by Kuraray Co., Ltd.), 12 parts by weight of bentonite (BENTONITE FUJI, manufactured by Hojun Kogyo Co., Ltd.), 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com