Pedal transmission for spin-drier

A pedal transmission and dryer technology, which is used in transmission devices, gear transmission devices, carpet cleaning, etc., can solve the problems of incomplete mop dehydration, low rotation speed of the dryer, poor transmission effect, etc., to achieve convenient lubrication, improve Transmission efficiency, the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

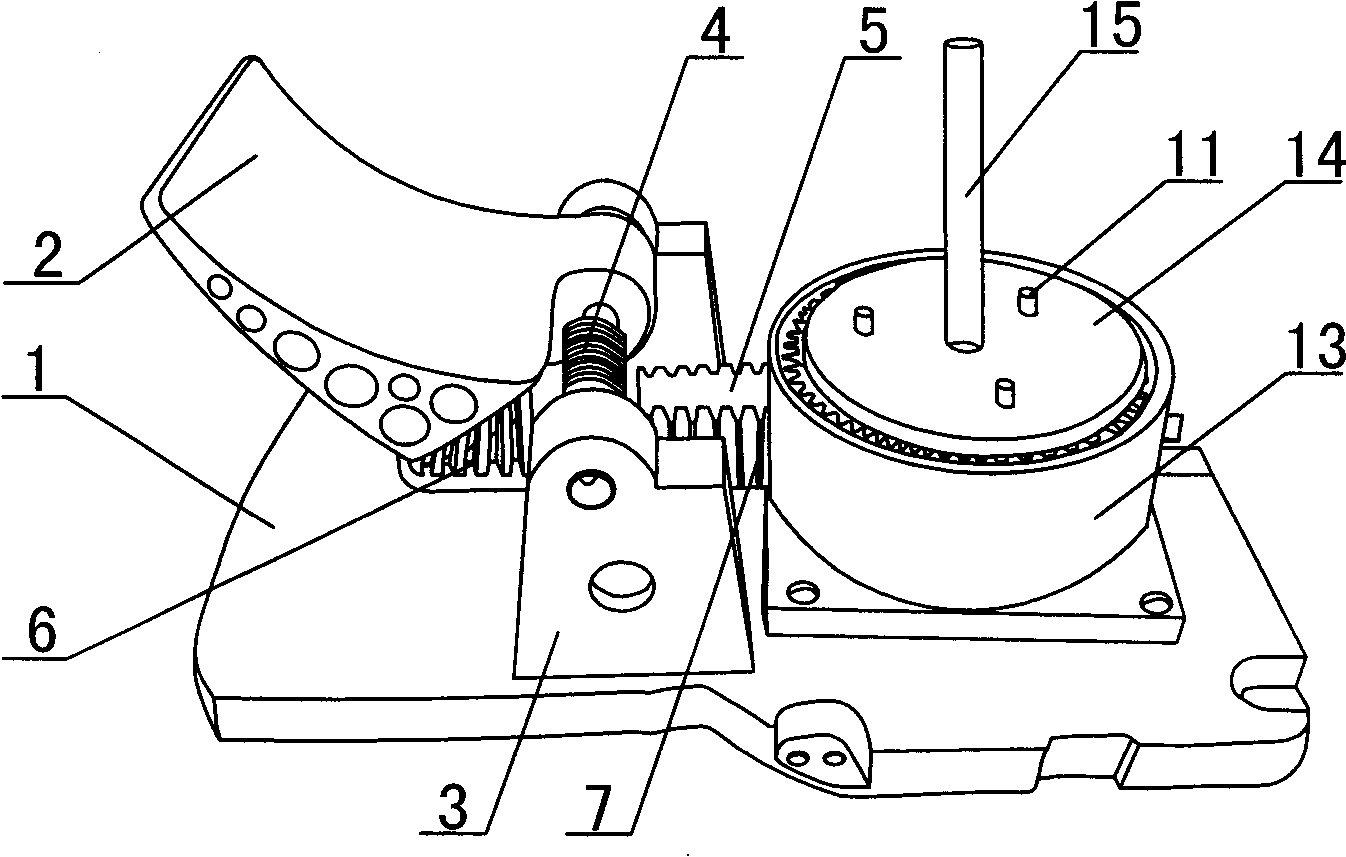

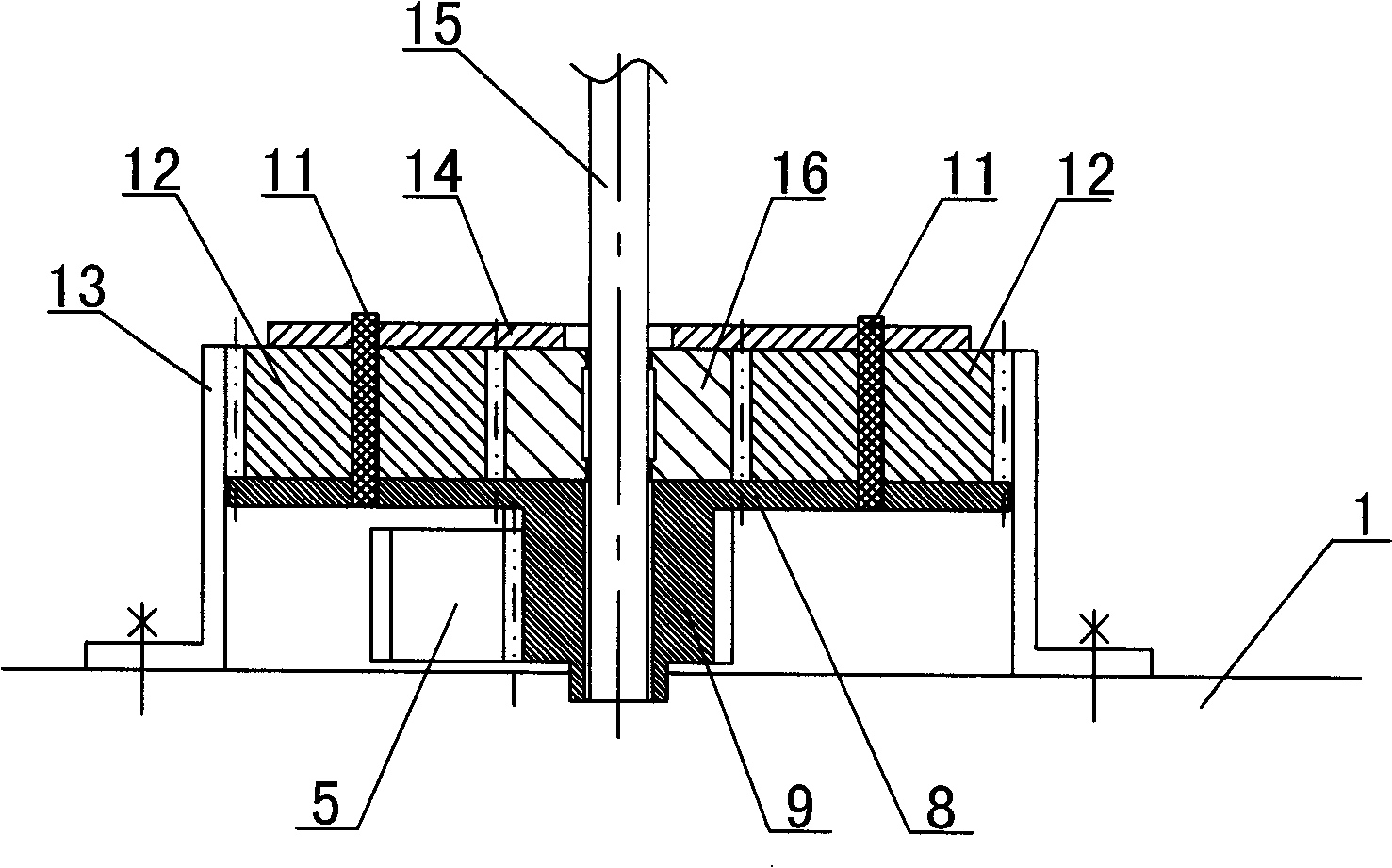

[0018] A specific embodiment of the spinner pedal transmission device of the present invention is provided below, as Figure 6 Shown, during use, it is installed in the bottom of cleaning bucket 17, drives the drier installed in the bucket to realize the dehydration of mop.

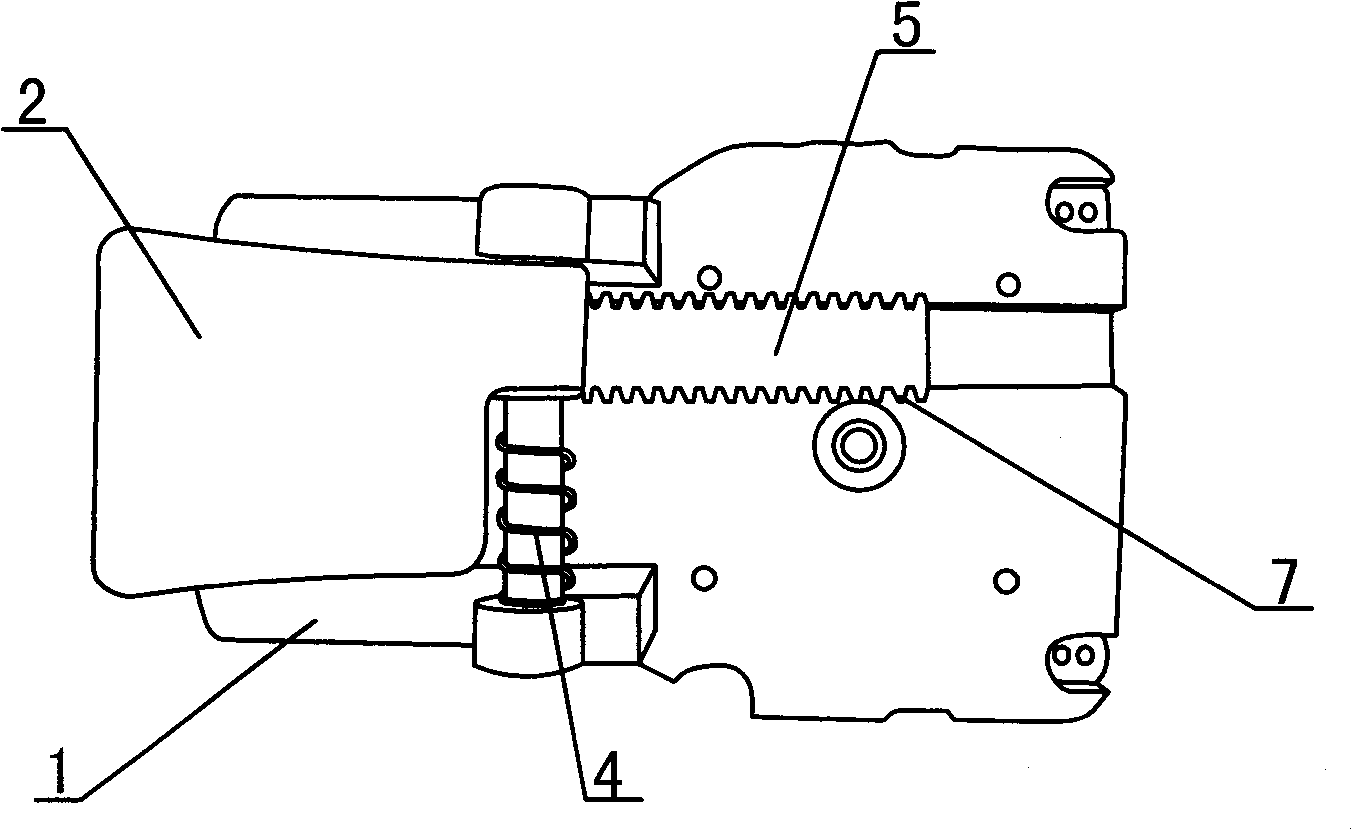

[0019] Its composition is as Figure 1-5 As shown, there is a fixed axle frame 3 on the base 1, and the pedal 2 is installed on the axle frame 3 through a shaft. In the hole, the other end is stuck in the side hole of the axle frame 3, so that the pedal 2 returns to its original position by the elastic force after being trampled downward; a chute is opened on the base 1 below the axle frame 3 A toothed rack 5 that can move back and forth is embedded in the chute. Flat teeth 6 are arranged on one end of the rack 5, and vertical teeth 7 are arranged on the side of the other end. The fan teeth on the pedal 2 and the rack 5 The flat teeth 6 form a rack and pinion transmission mechanism through meshing, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap