Bunker dredging system with arch breaking cap using resonance method

A technology of coal bunker and arch cap, which is applied in the field of resonant method coal bunker dredging system of broken arch cap, can solve the problems of poor use effect, potential safety hazards, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

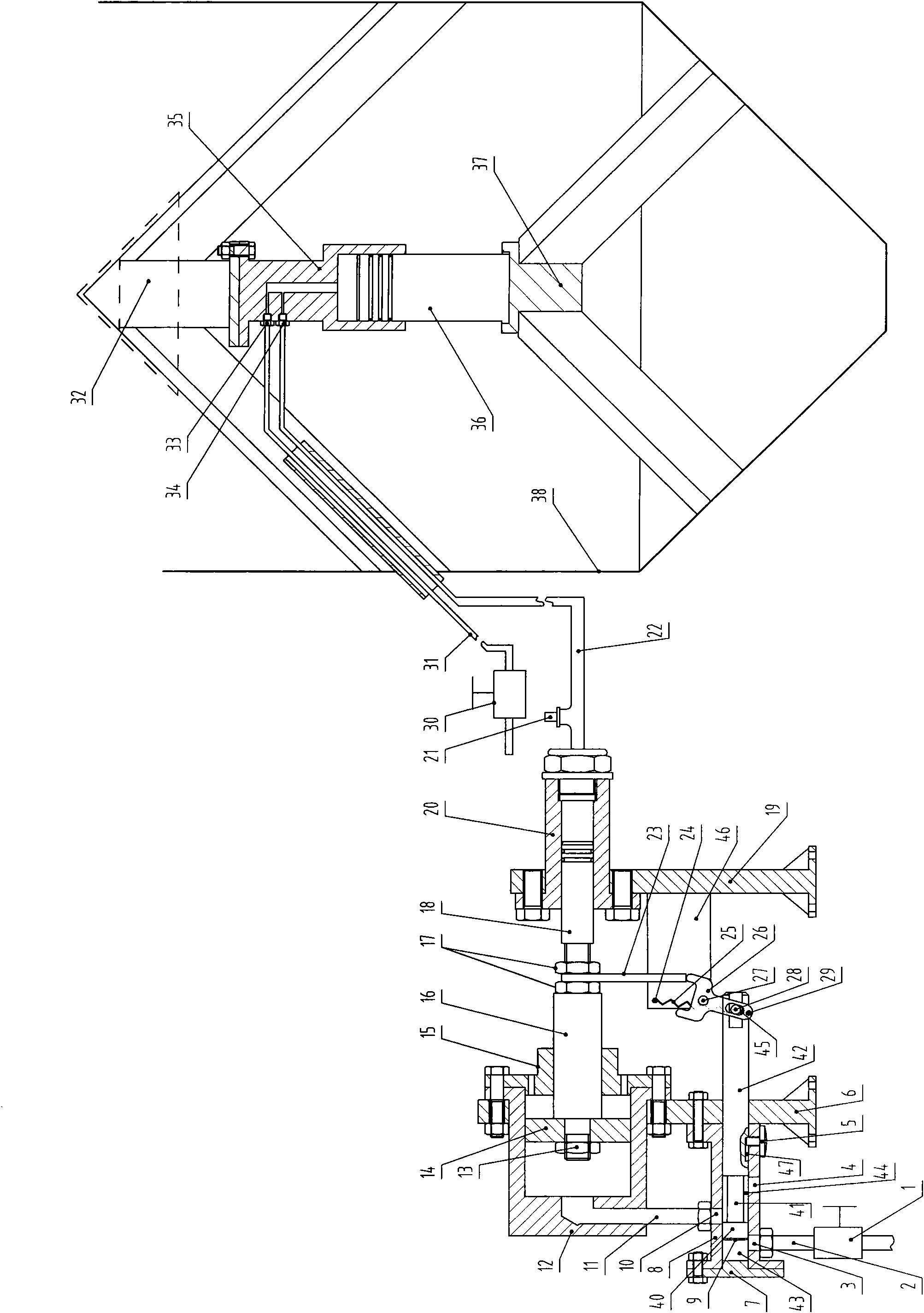

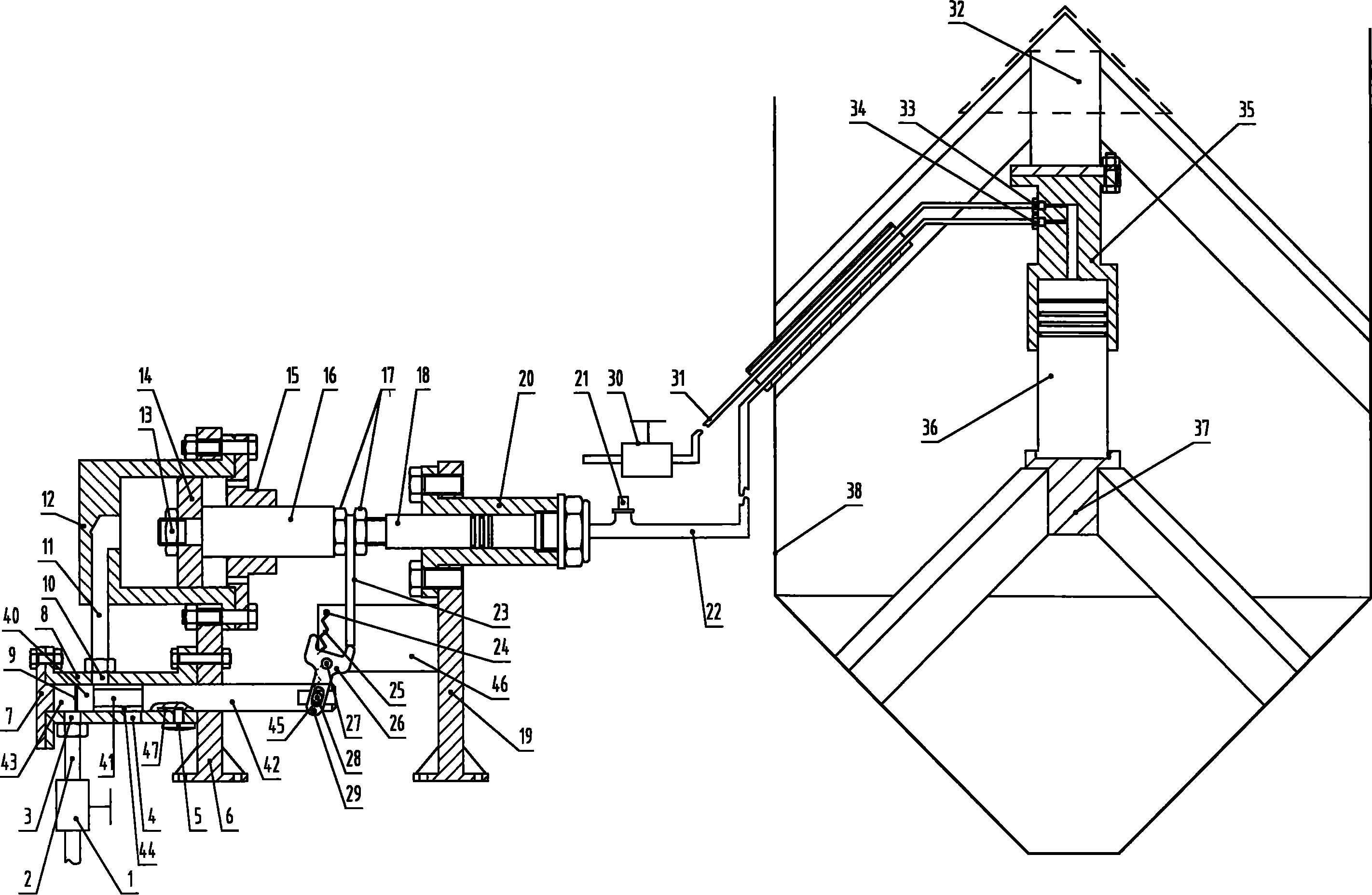

[0018] Such as figure 1 As shown, the coal bunker dredging system of the broken arch cap resonance method of the present invention includes an automatic reversing device, an exciting force device and a main vibrating body device, the automatic reversing device is arranged on the support 6, and the exciting force device is located on the automatic The reversing device is above and fixedly connected to the support 6 and the support 19. The power output end of the automatic reversing device is connected with the power input end of the exciting power device through the pipeline 11 pneumatic or hydraulic power transmission, and the power output end of the exciting power device is connected with the reversing valve core 9 of the automatic reversing device. The power output end of the vibrating force device is connected with the main vibrating body device through a pipeline 22 through a hydraulic transmission.

[0019] The automatic reversing device includes a valve body 8 having an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com