Remote control combination type railway temporary beam rapid loader

A combination of loading and unloading machine technology, applied in the direction of cranes, etc., can solve the problems of blocking the section for more than one hour or even two hours, the economic loss of railway transportation, and reducing the number of trains in operation, so as to achieve light weight and reduce economic costs. Loss, the effect of reducing the blocking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

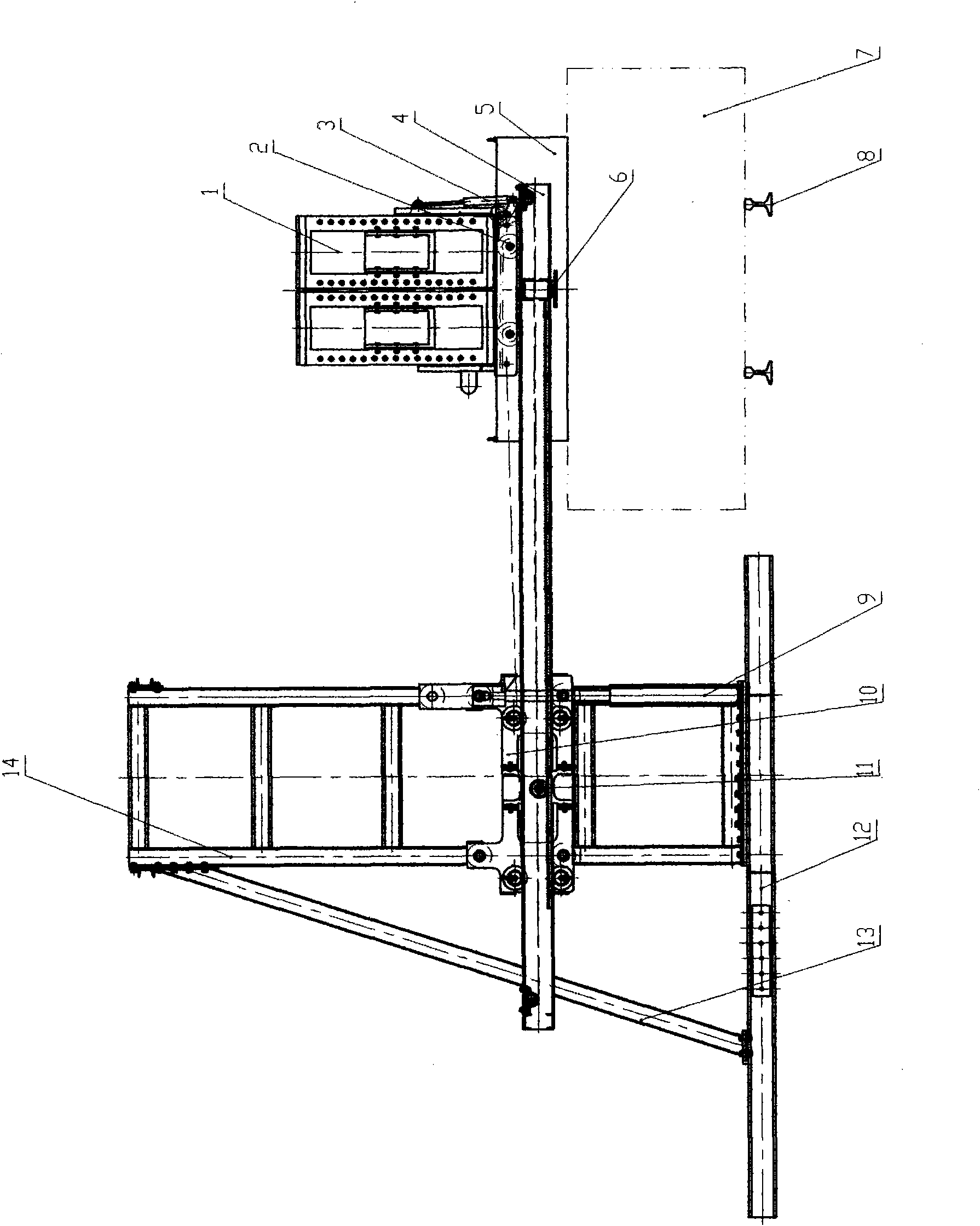

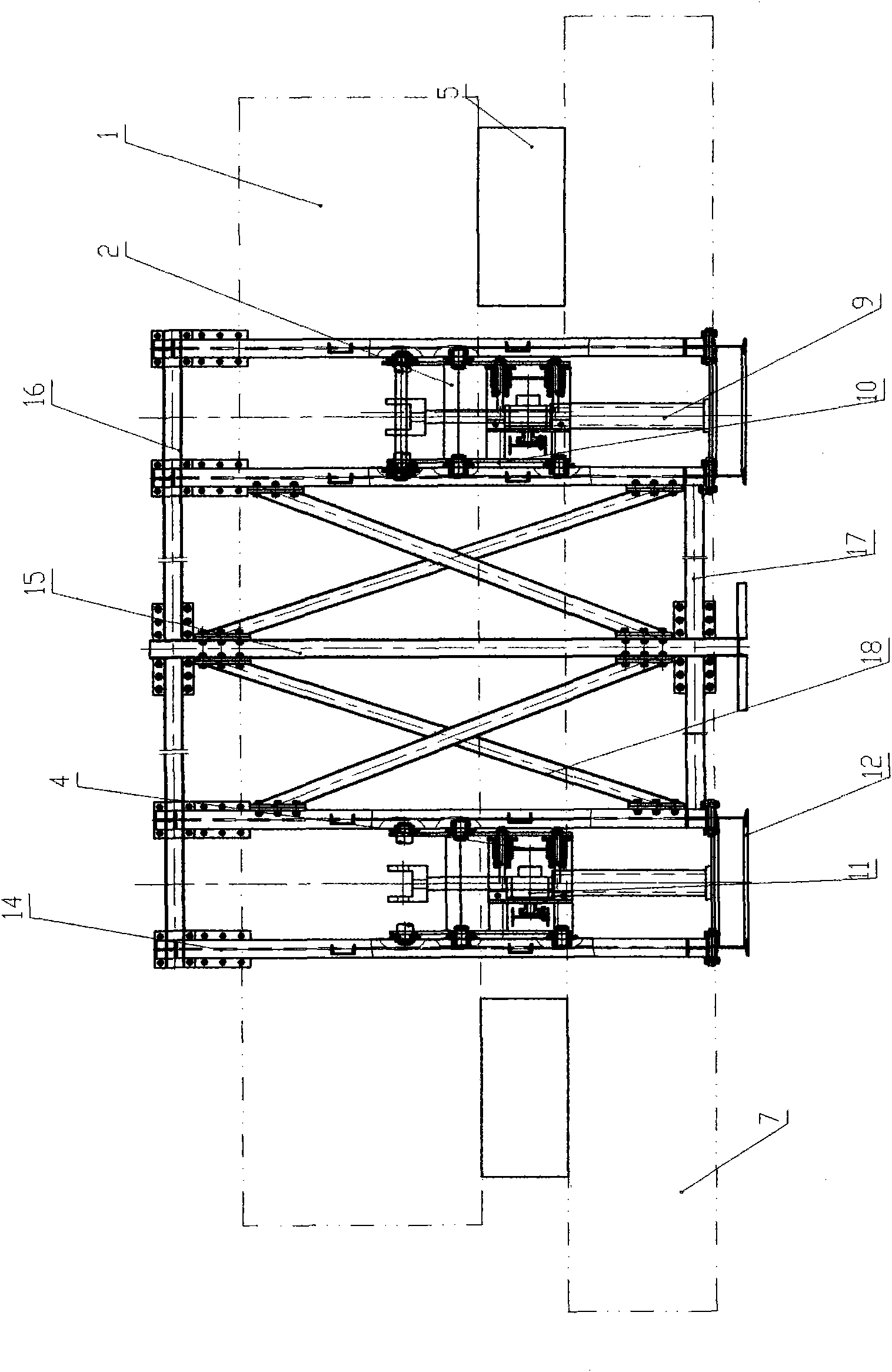

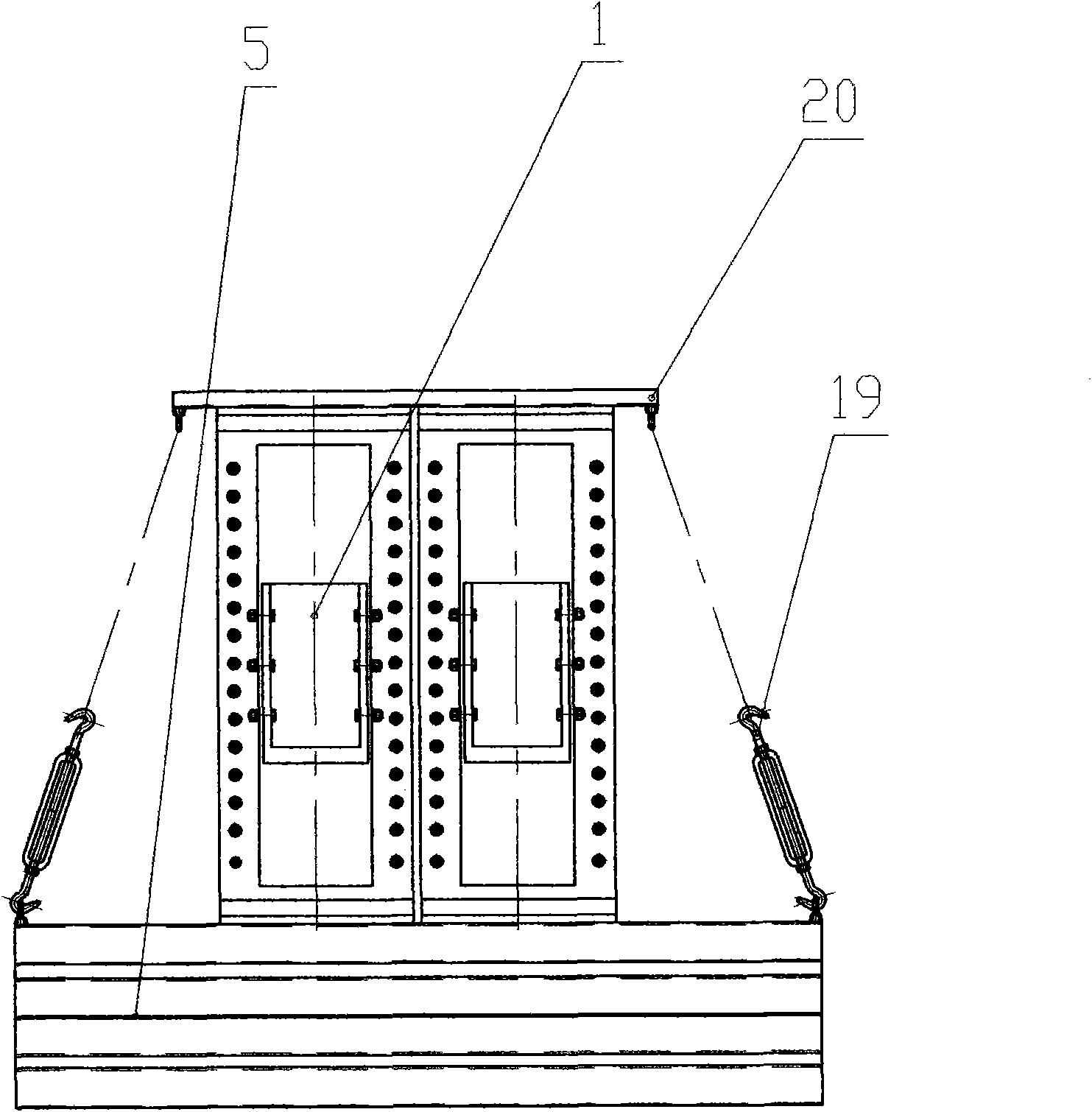

[0025] refer to figure 1 , Figure 6 As shown, the remote control combined type railroad beam fast loading and unloading machine of the present invention comprises a frame, a hydraulic system and an electric control system; One upper connecting beam 16, four lower connecting beams 17, and eight rack reinforcement beams 18 are connected; the roller frame 10 and the secondary lifting cylinder 9 are respectively installed in the column rail 14, and the horizontal telescopic rail 4 is horizontally installed in the roller frame 10. The trolley 2 is installed on the horizontal telescopic track 4, and is connected with the hydraulic motor 28 installed on the left side of the horizontal telescopic track through chains and sprockets, and the lift cylinder 6 is installed on the right side of the horizontal telescopic track; it is characterized in that: the roller frame passes through Connected with the secondary lifting cylinder, it drives the horizontal telescopic track to move up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com