Dual-tube injection well safety production string

A technology for safe production and injection wells, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc. problem, to achieve the effect of large dispensing and dispensing diameter and convenient deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

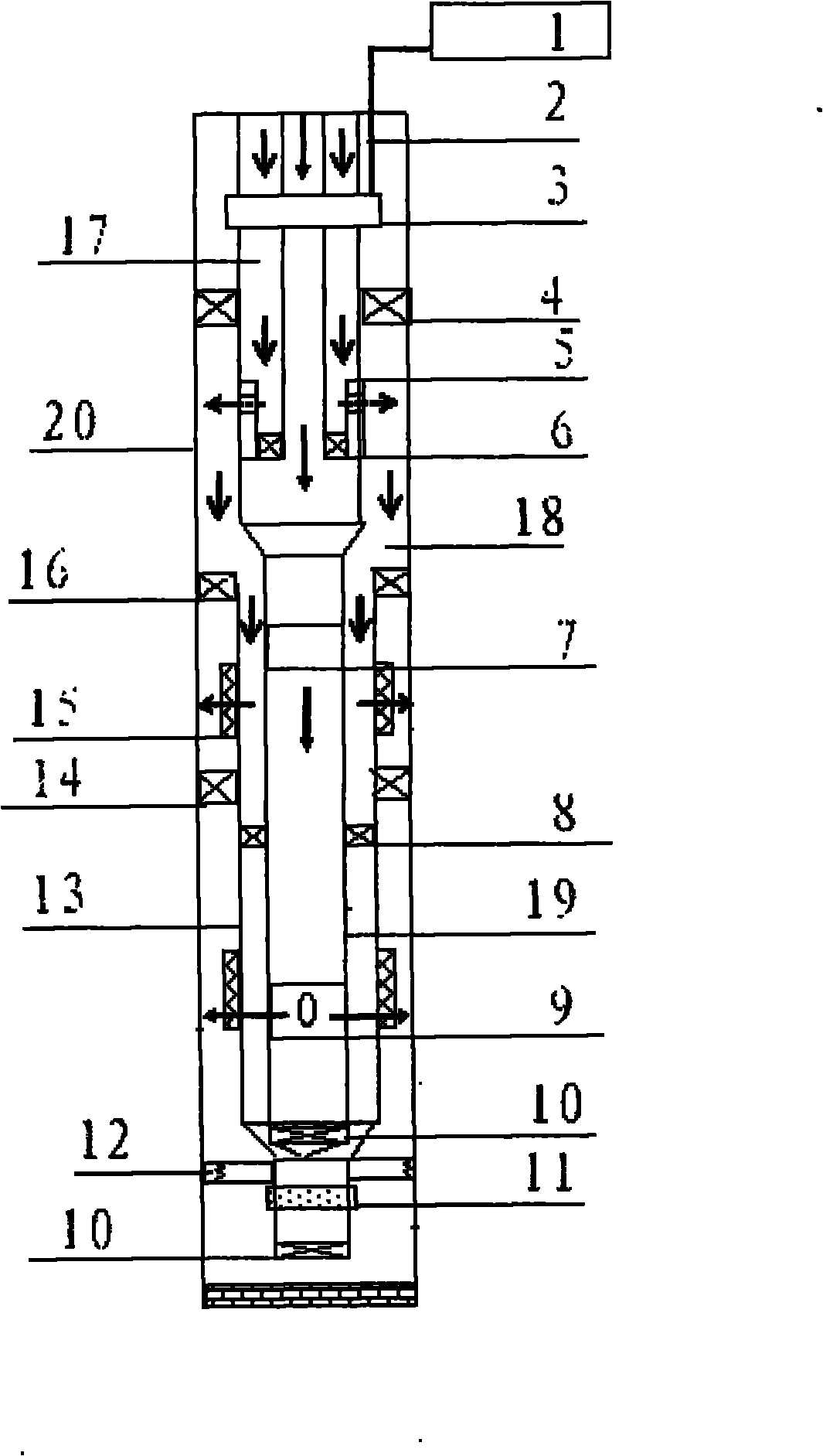

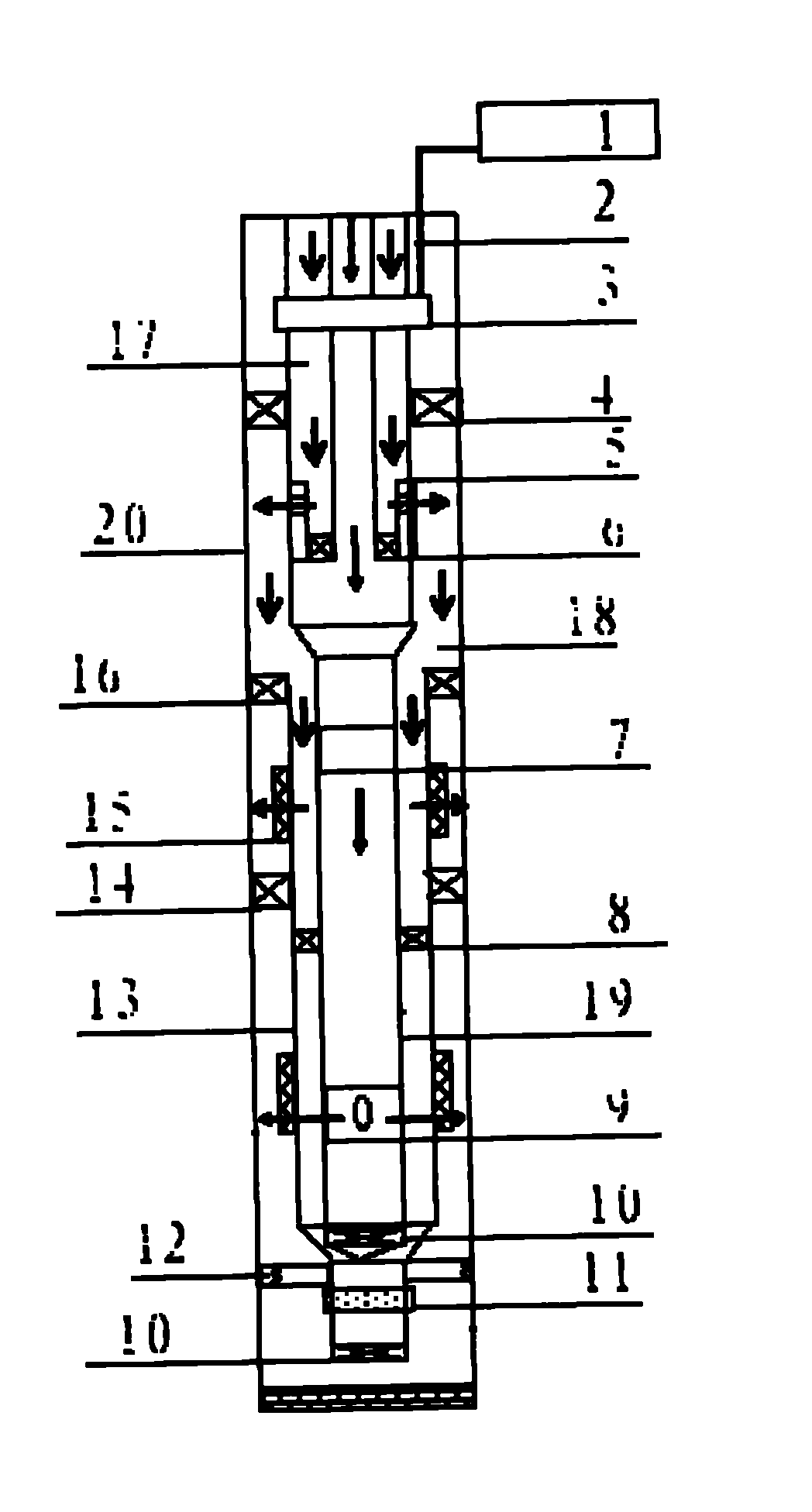

[0013] Referring to the accompanying drawings, a double-pipe injection well safety production string includes a surface control system 1, a hydraulic control pipeline 2, an annular safety valve 3, an annular packer 4, a positioning injection valve 5, a sealing plug 6, Pipe string, injection safety valve 7, injection layered packer 8, injection valve 9, plug 10, bottom sand filter pipe 11, anchor 12, sand control packer 14, sand control screen 15, sand control string 13 , casing string 20 and water injection string 19. The upper part of the water injection string 19 is installed in the casing string 20 , and the lower part is installed in the sand control string 13 . The sand control string 13 is installed in the casing string 20 . A suspension packer 16 is installed on the upper part of the sand control string 13 , and the lower part is connected with the anchoring device 12 . Annulus safety valve 3, annulus packer 4, positioning injection valve 5, sealing plug 6, injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com