Single-acting plunger type buffering hydraulic oil cylinder

A hydraulic cylinder and plunger type technology is applied in the field of single-acting plunger type buffer hydraulic cylinders, which can solve the problems of forklift tremor, affecting the strength and normal operation of the hydraulic system of the hydraulic cylinder, avoiding tremor, ensuring strength and smooth operation, The effect of avoiding shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

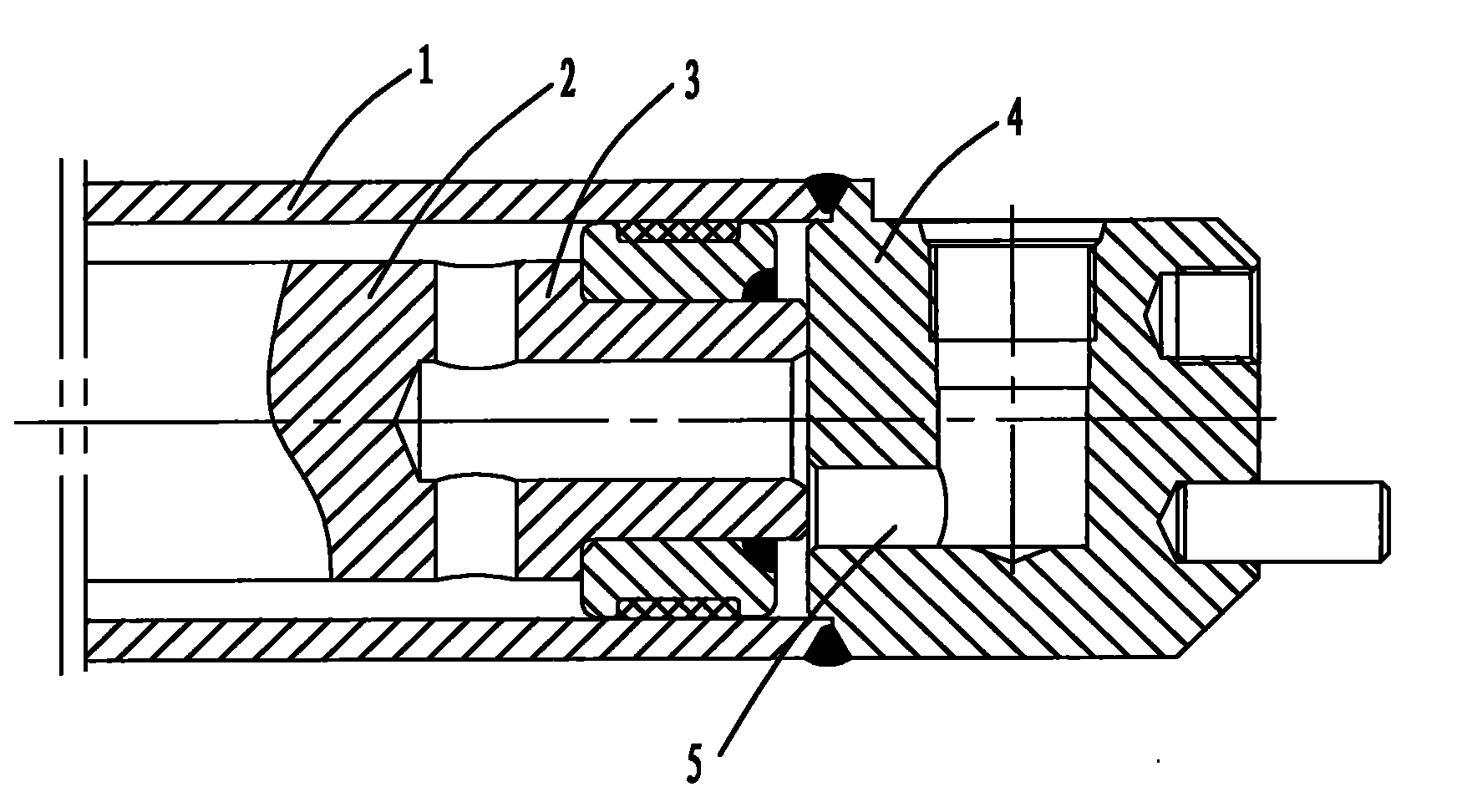

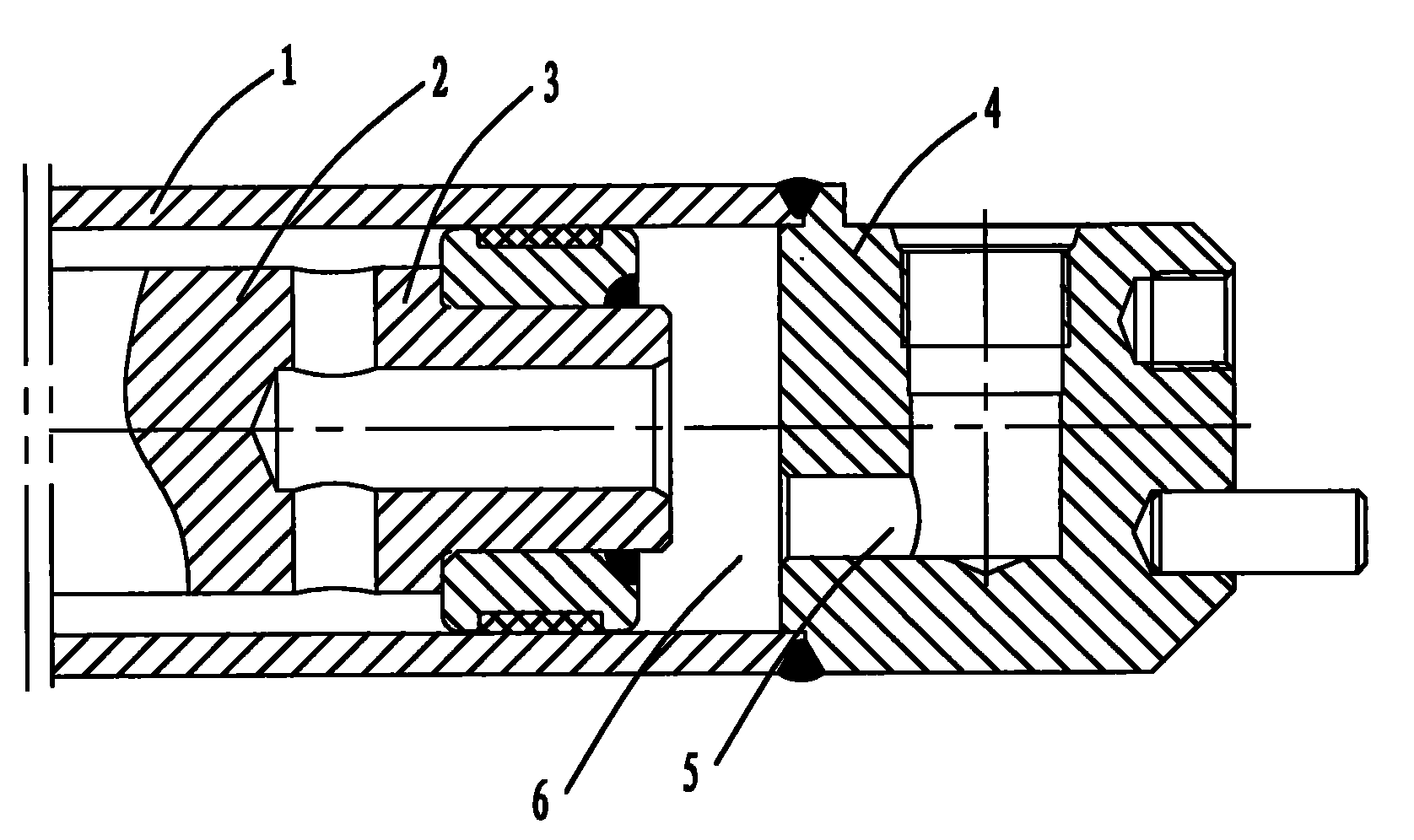

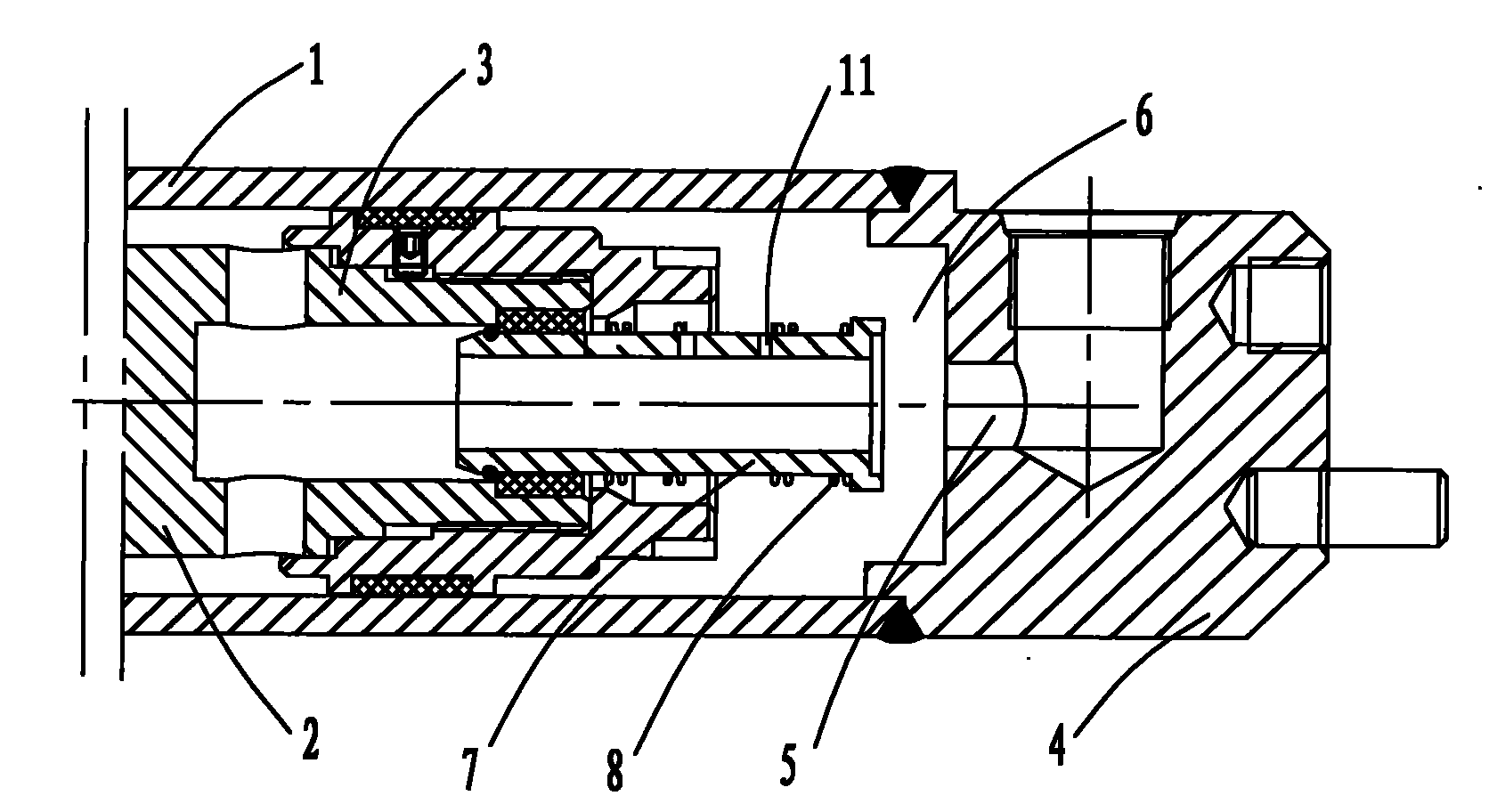

[0015] Example: Combined image 3 , the plunger-type buffer hydraulic cylinder of this embodiment includes a cylinder body 1, a piston 3, a plunger rod 2 connected to the upper end of the piston 3 to drive the movement of an external mechanism, and the hydraulic oil enters the oil chamber 6 from the oil port 5 at the bottom of the cylinder 4 Inside, pressure is generated to drive the piston 3 upward to complete the lifting action. At the same time, the spool 7 moves upward with the piston under the force of its external spring 8. The stop ring 9 contacts with the sealing ring 10 to form a limit, preventing the spool 7 from detaching from the piston 3. After the lifting work is completed, Figure 4 As shown, under the action of gravity of the external fork, mast and plunger rod, etc., the piston 3 descends rapidly in the cylinder body 1, and the hydraulic oil in the oil chamber 6 returns rapidly from the oil port 5, when the bottom of the valve core 7 After contacting the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com