Steel support shaft stress adaptive system real-time compensating hydraulic oil cylinder for base pit

An adaptive system, real-time compensation technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of wall displacement, affecting subway safety, difficult to apply supporting axial force, etc., to improve accuracy and reliability, improve overall safety and reliability, and the effect of ensuring reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

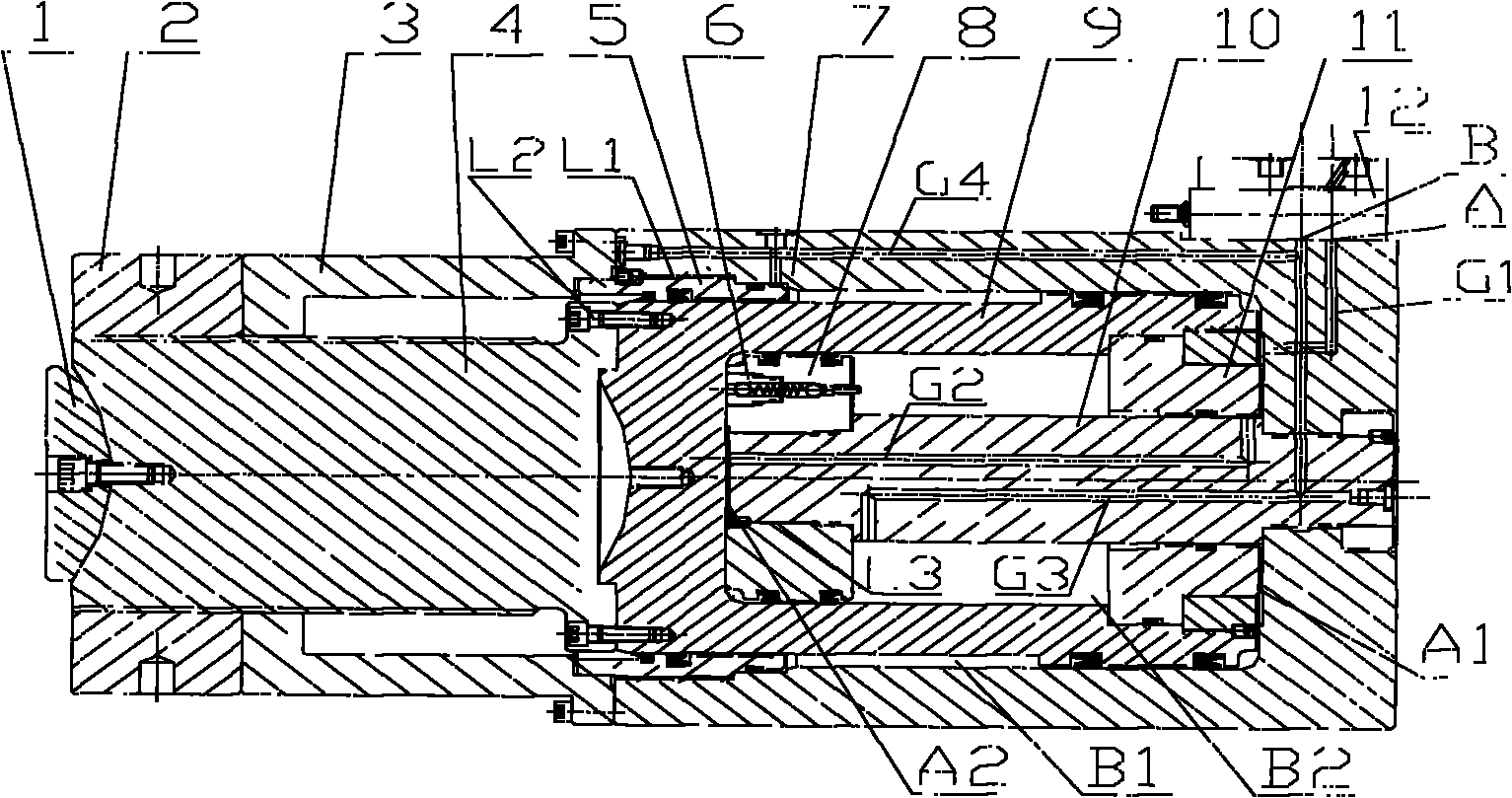

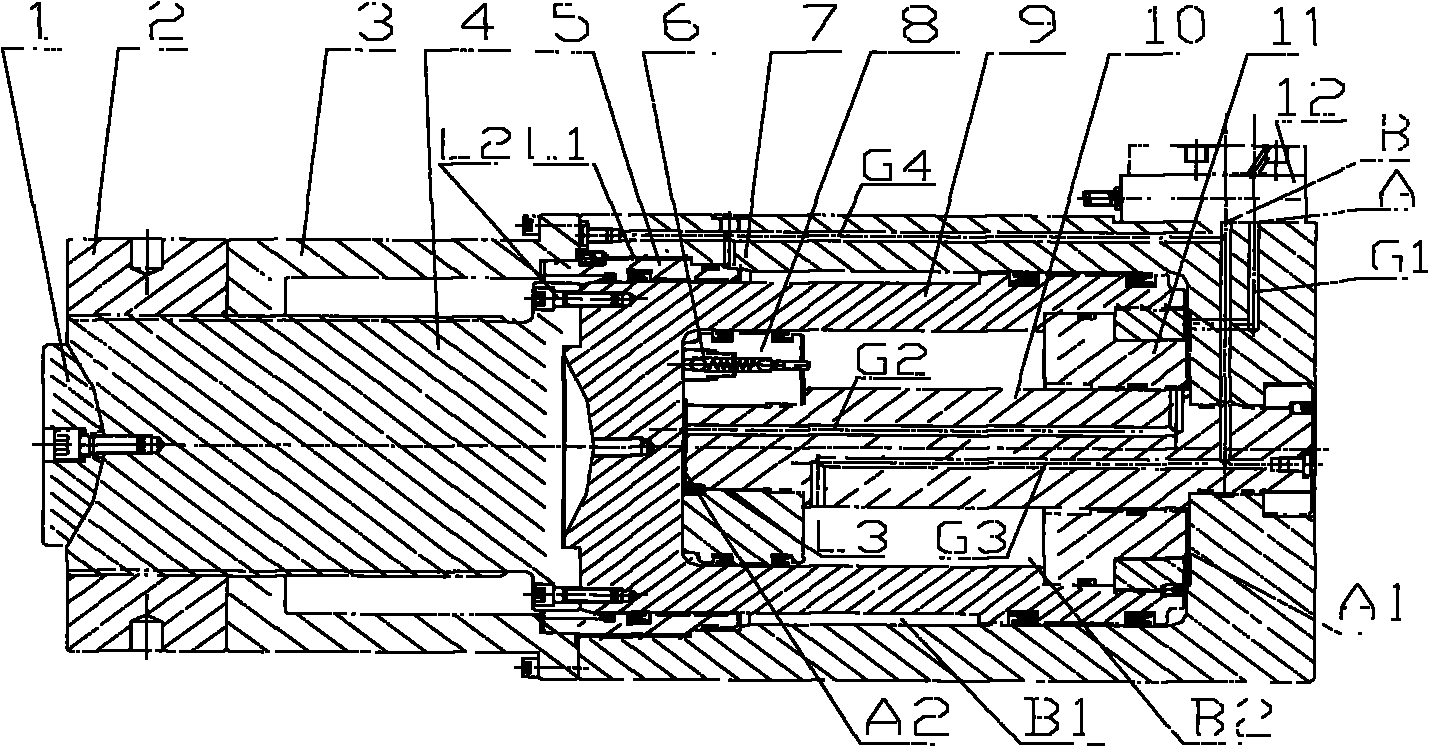

[0029] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

[0030] figure 1 Shown is a structural schematic diagram of the real-time compensation hydraulic cylinder device of the foundation pit steel support axial force self-adaptive system proposed by the present invention. like figure 1 As shown, the first guide sleeve 5 is arranged in the cylinder body 7; the first piston rod 9 is arranged in the cylinder body 7 through the first guide sleeve 5, and the first piston rod 9 has an axial cavity with an open end, wherein The second guide sleeve 11 is arranged in the axial cavity; the second piston rod 10 is arranged in the axial cavity in the first piston rod 9, and the piston 8 is arranged in the free end of the second piston rod 10; The piston rod 9, the second piston rod 10, the second guide sleeve 11 and the cylinder body 7 form the first oil inlet cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com