X-ray crystal orientation device

An orientation instrument and X-ray technology, applied in the field of X-ray detection devices, can solve problems such as unsatisfactory, reprocessing, re-submission, waste of raw materials, and long chip usage time, etc., so as to shorten the inspection period and detect Good effect, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

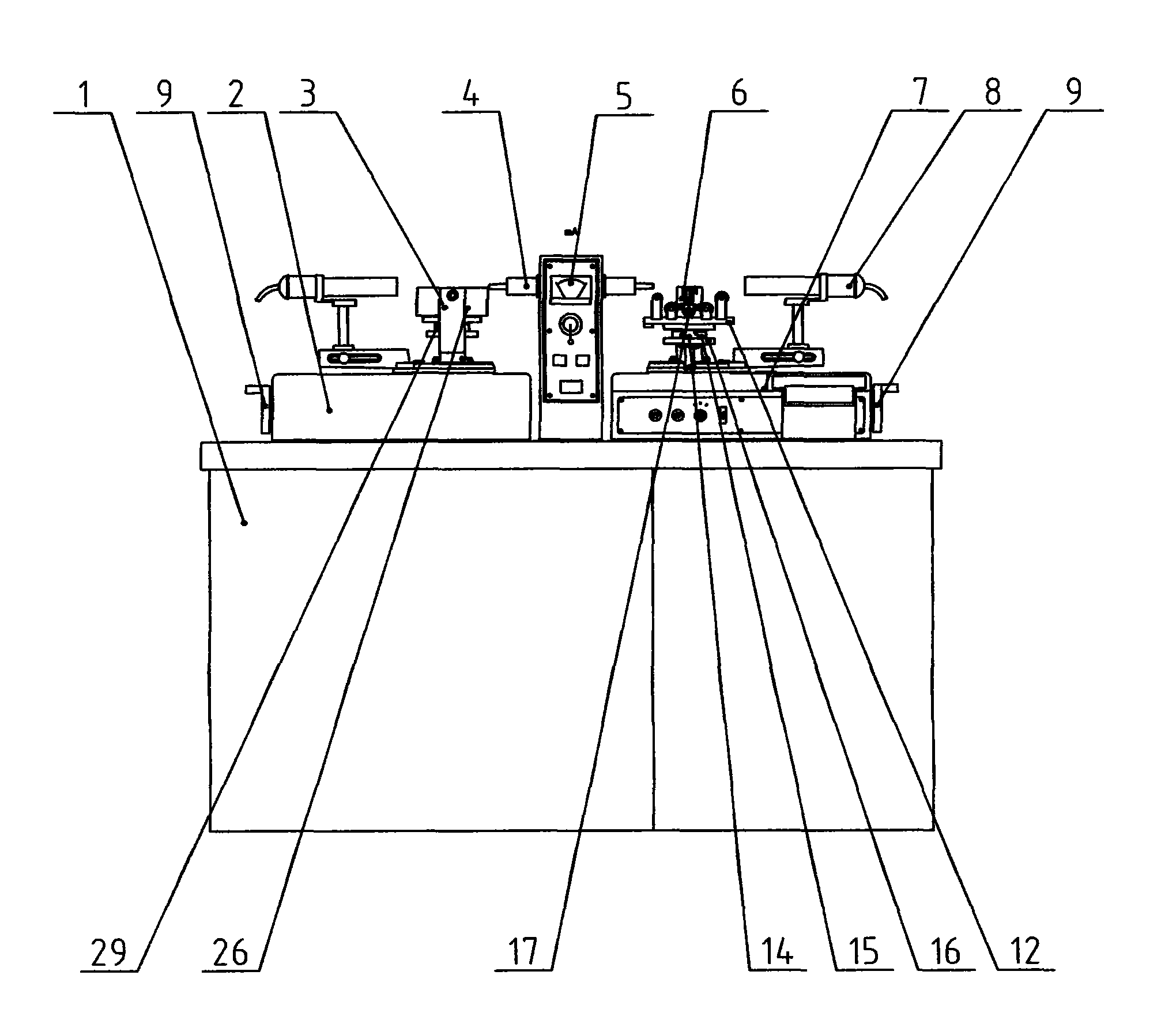

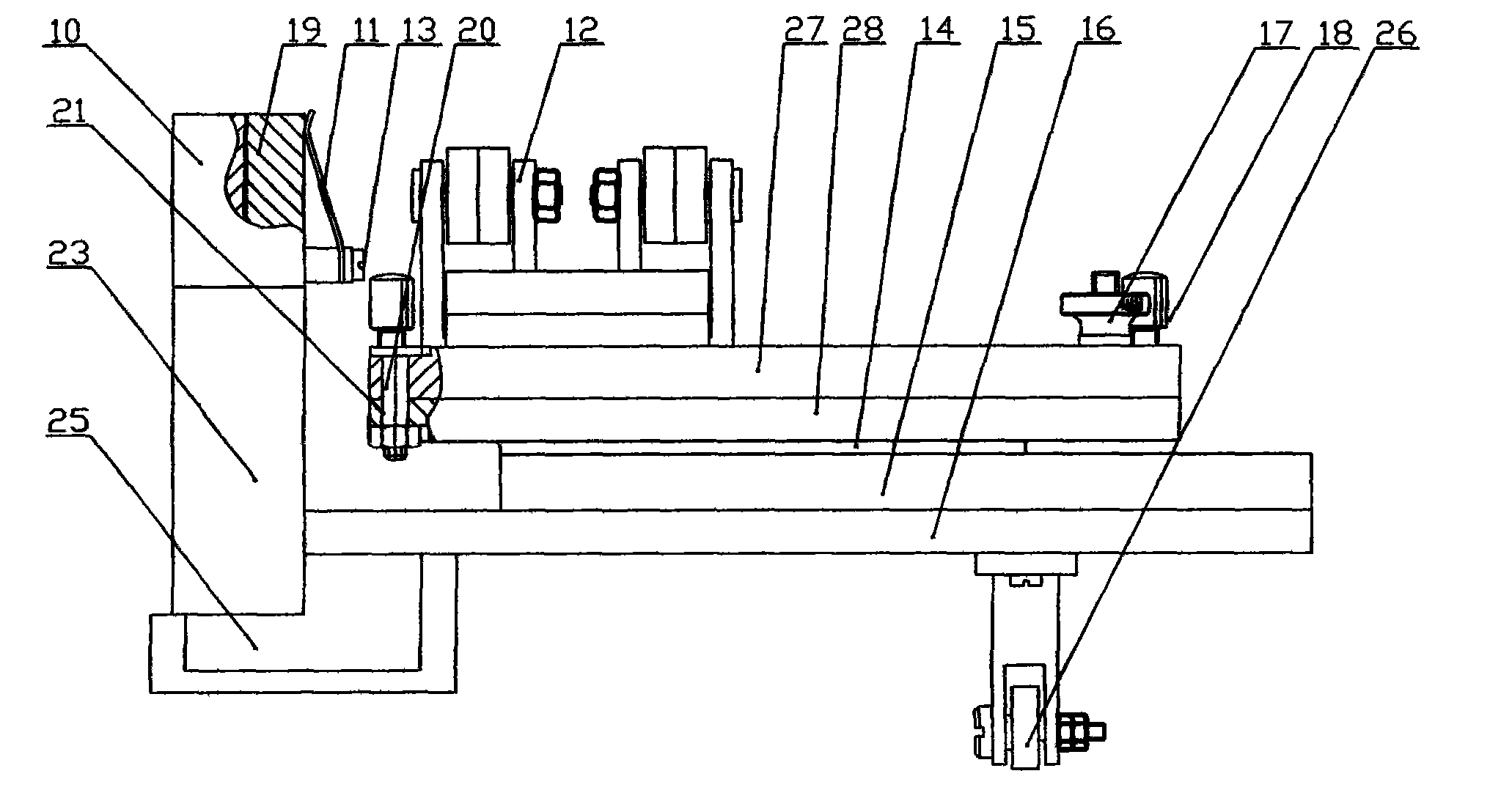

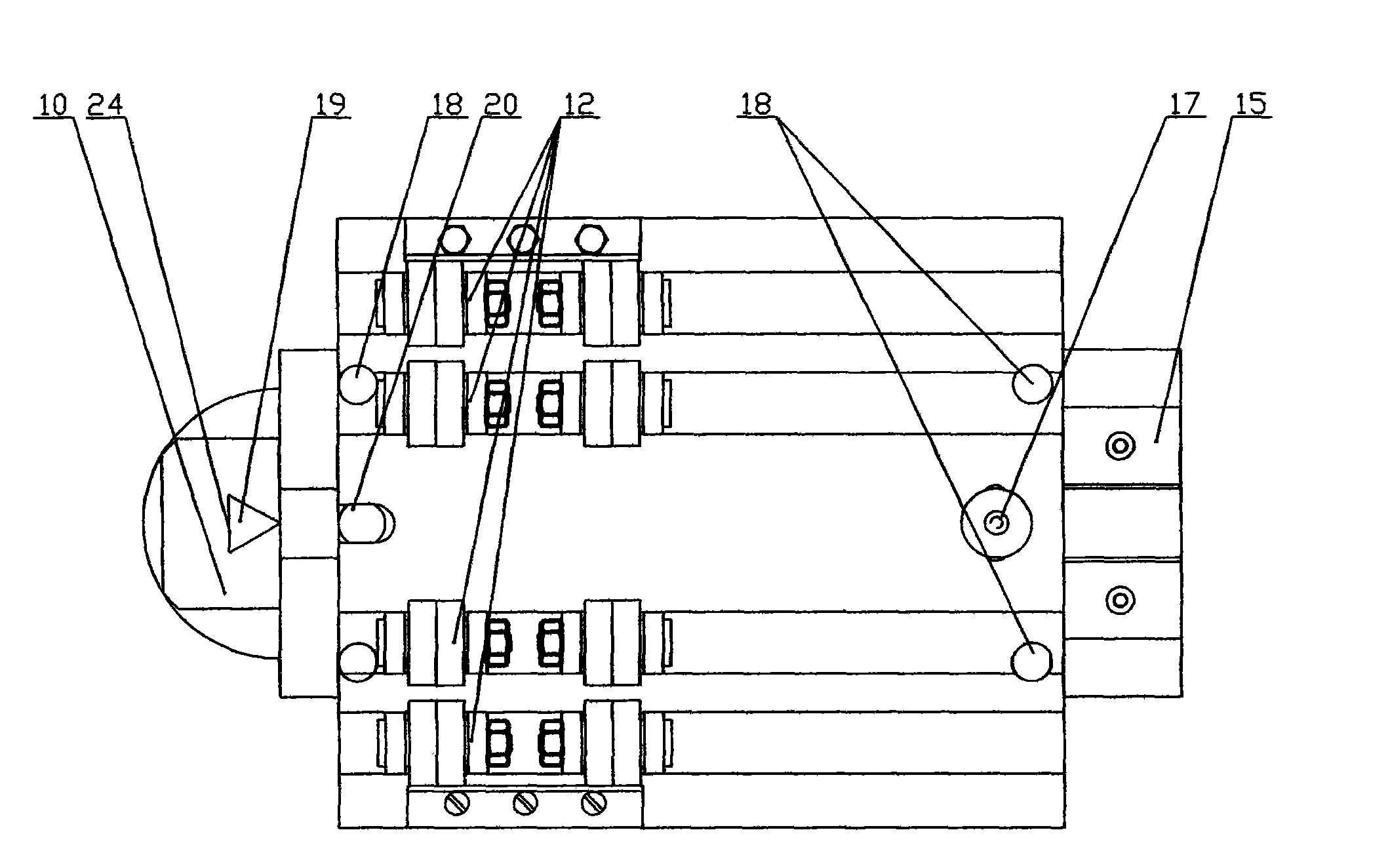

[0017] An X-ray crystal orientation instrument, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, it includes a table body 1 and an X-ray tube cover 5 arranged on the table body 1, two light barriers 4, a goniometer 2 and a goniometer 7, and the goniometer 2 and the goniometer 7 are arranged on the The hand wheel 9 and the left sample stage 3 and the right sample stage 6 and the counter tube 8 installed coaxially with the goniometer, the goniometer adopts a worm gear structure, rotating the handwheel 9 can make the left sample stage 3 and the right sample stage 6 on the goniometer The right sample stage 6 rotates, and the counter tube 8 can be manually rotated coaxially with the goniometer. The X-rays are emitted from the tube sleeve 5, pass through the aperture 4, and hit the inspected crystal in the center of the sample stage. Different c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com