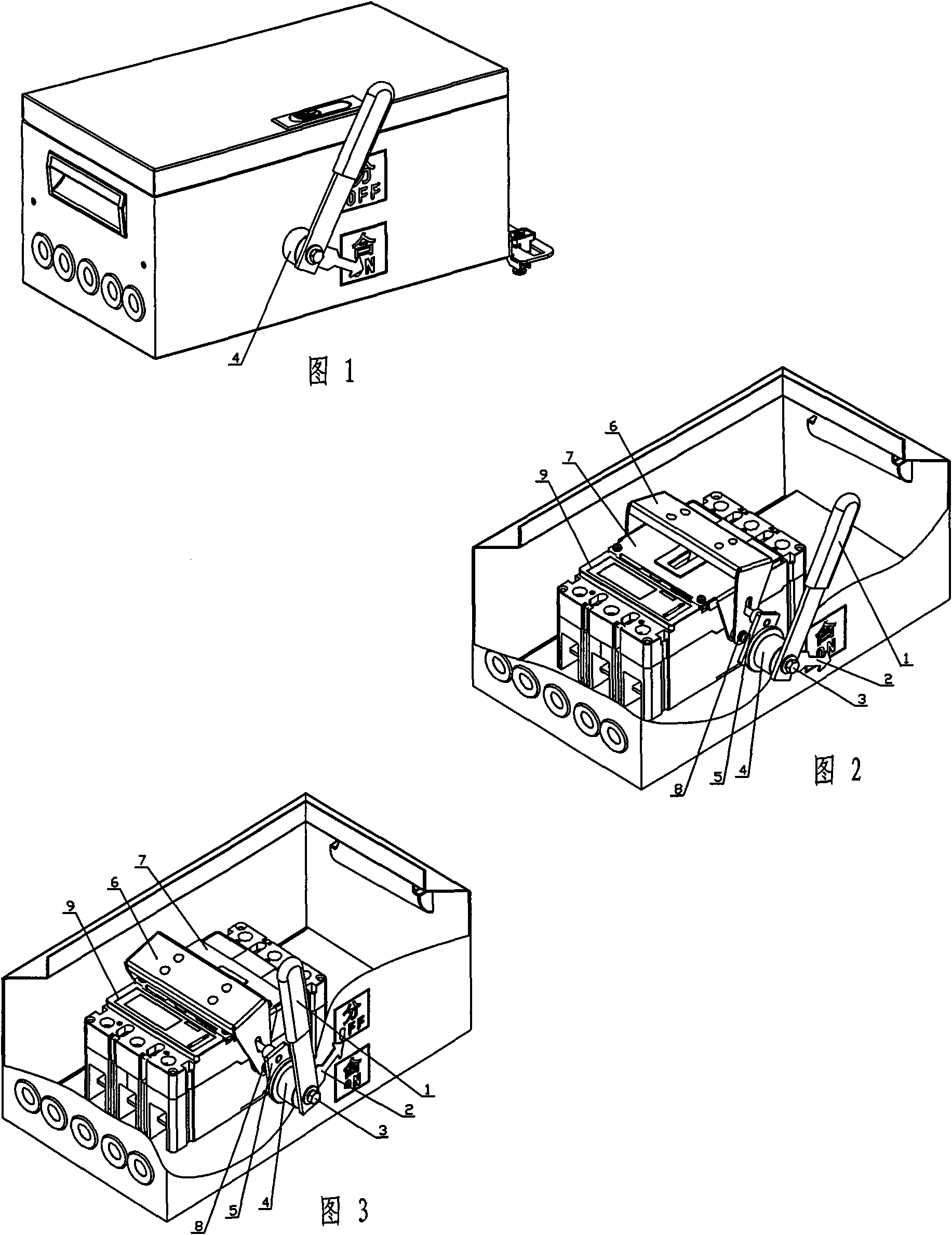

Manual operating mechanism of jack box

A technology of manual operation and plug-in box, which is applied in the direction of contact drive mechanism, contact operation parts, air switch components, etc., which can solve potential safety hazards, laborious operation of the rotary handle, and easy access to the electrical circuits in the box by the operator. problems, to achieve the effect of simplifying operating procedures, protecting personal safety and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

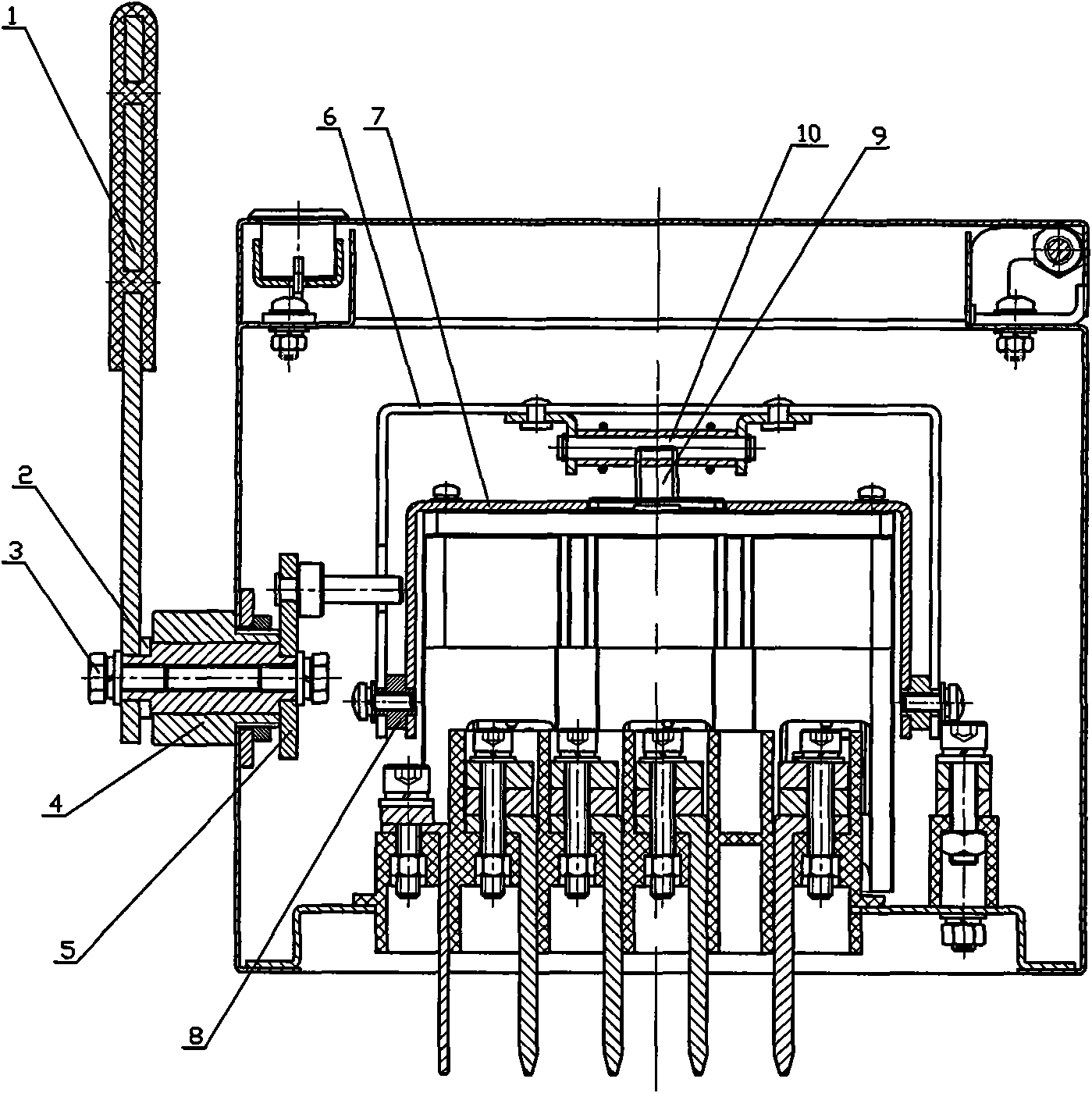

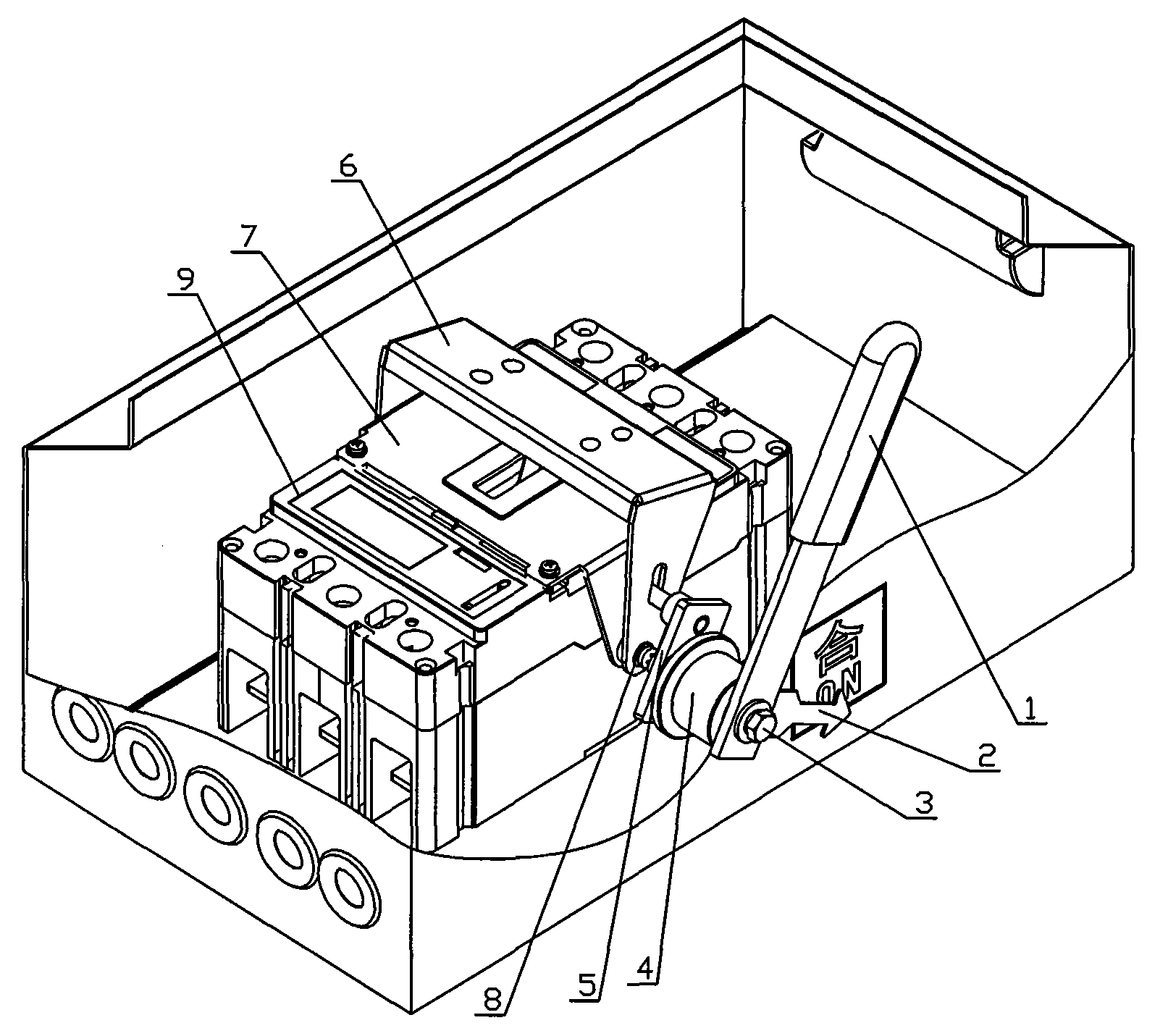

[0014] As shown in the figure, the manual operation mechanism of the plug-in box of the present invention consists of an operating handle 1, an indicator plate 2, a rotating shaft 3, a fixed sleeve 4, a toggle lever assembly 5, a rocker arm bracket 6, a rocker plate base 7, and a shaft sleeve 8 , Molded case switch 9; the fixed sleeve 4 is fixed on the outer shell of the plug-in box, the rotating shaft 3 passes through the small hole at the end of the operating handle 1, the opening and closing indicator 2, and is placed inside the fixed sleeve 4, and can be placed inside the fixed sleeve 4 Internal rotation; a toggle lever assembly 5 is fixed at the inner end of the rotating shaft 3, and a cylindrical protrusion is inserted into the waist-shaped hole of the rocker bracket 6 legs on the upper part of the toggle lever assembly 5. There are connecting holes, and the shaft sleeve 8 fixes the rocker bracket 6 through the connecting holes on the legs of the rocker bracket 6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com