Method for controlling a field device in automation engineering

A technology for controlling automation and field equipment, which is applied in general control systems, sequence/logic controllers, program control, program control, etc., can solve problems such as the inability to guarantee 100% off-line control, and achieve the effect of reducing test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

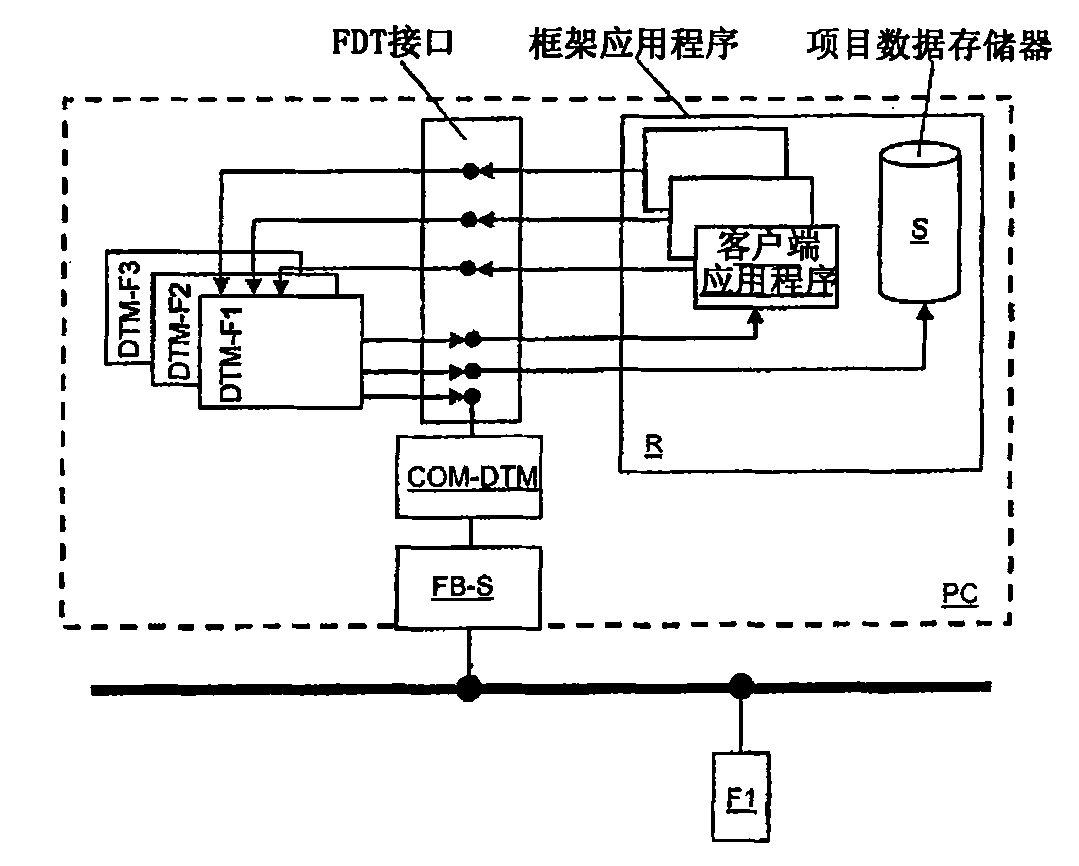

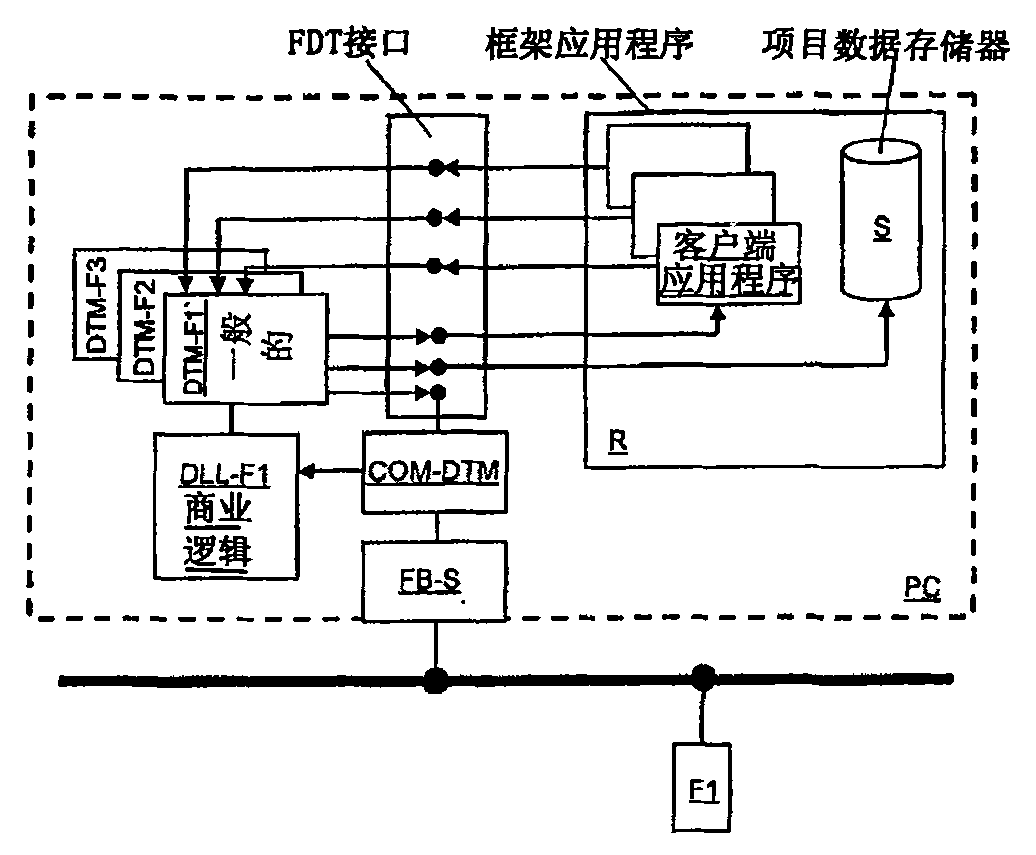

[0036] figure 1 Schematically shows the components required to control the field device F1. Usually the control takes place by means of the computer unit RE. The computer unit RE can be, for example, a personal computer PC with a Windows operating system. The computer unit RE is connected via a fieldbus interface FB-S to a fieldbus FB, to which the field device F1 is connected. Running on the computer unit RE is a framework application R (eg FieldCare from the company Endress+Hauser), which communicates via a defined interface (FDT interface) with a device DTM DTM-F1 assigned to the field device F1. There are also other device DTMs, namely DTM-F2 and DTM-F3 for field devices F2 and F3 not shown in detail.

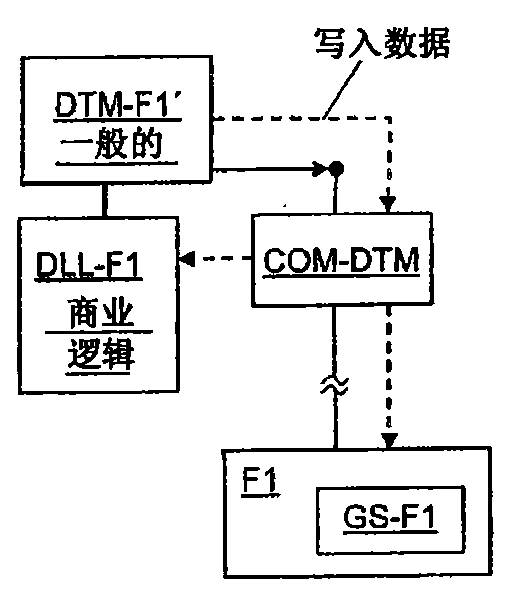

[0037] The device DTM DTM-F1 is connected to the fieldbus interface FB-S via the communication DTM COM-DTM. In order to control the field device F1, the device DTM of the field device involved (here the device DTM DTM-F1) must be instantiated. The framework application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com