Spraying technology and special device for outer wall of wind power tower

A technology for wind power towers and special equipment, which is applied in the direction of coating, spraying devices, and devices for coating liquid on the surface, etc., which can solve the problems of large equipment occupation, large energy consumption, and environmental pollution, so as to reduce equipment energy consumption , high spraying quality, improve the effect of indoor environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

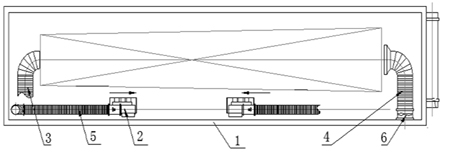

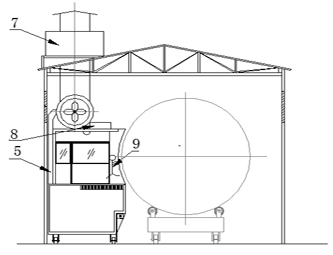

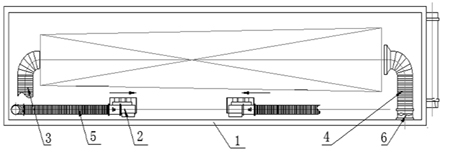

[0022] In an embodiment, a spraying process for the outer wall of a wind power tower includes the following steps: placing the tower in a closed environment, using two small painting operation trolleys to spray paint in this environment, the small painting operation trolley and the tower The outer surface of the cylinder is profiled to form a small spray booth. The small spray booths are connected to independent exhaust pipes. During the spraying process, the operator is located in the small spray booth to move and spray at variable speeds, forming efficient spraying in a small operating environment. Specific operation steps: the tower is transported by the transport roller bracket into the large paint spraying room, and rotates in situ; when the outer wall is sprayed, the spraying operation platform, that is, the small spray booth, moves along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com