Structure of mounting cowl top cover

A technology of cowl upper cover and installation structure, which is applied in the direction of upper structure, upper structure sub-assembly, transportation and packaging, etc., which can solve the deformation of the clamping part or fitting groove, reduce the quality of the vehicle, and the front wall upper cover To avoid excessive load, prevent falling, and restrain one-time shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

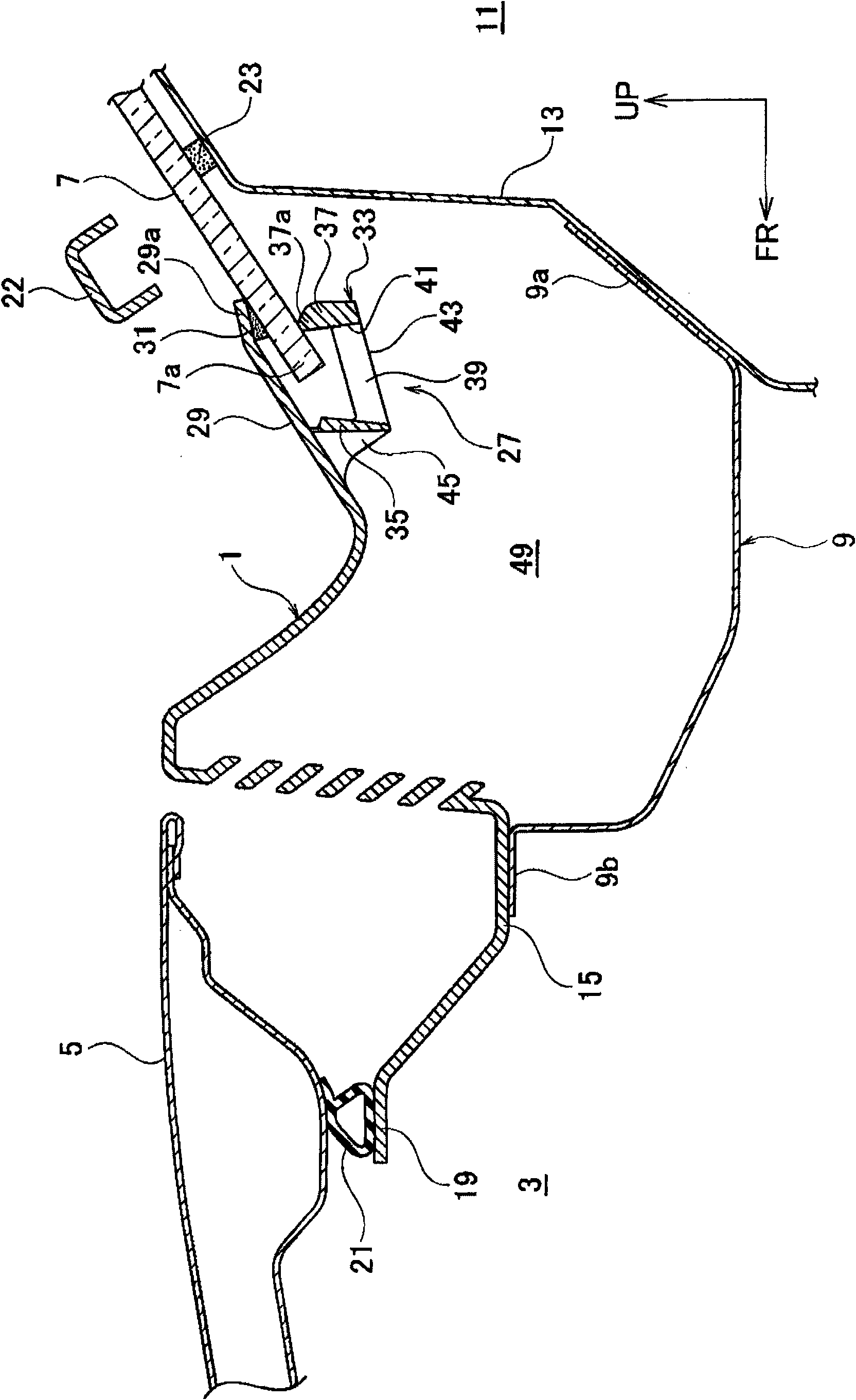

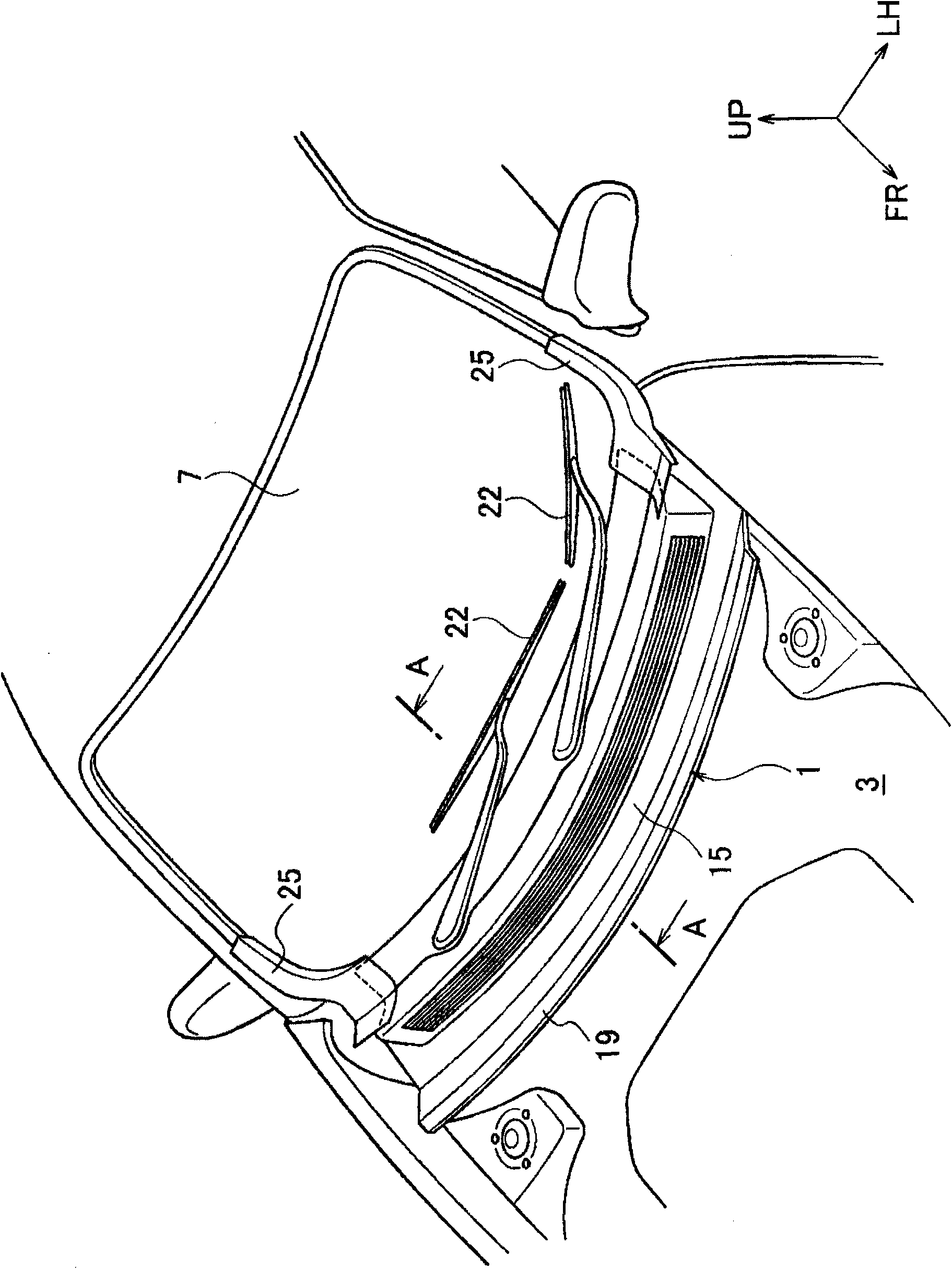

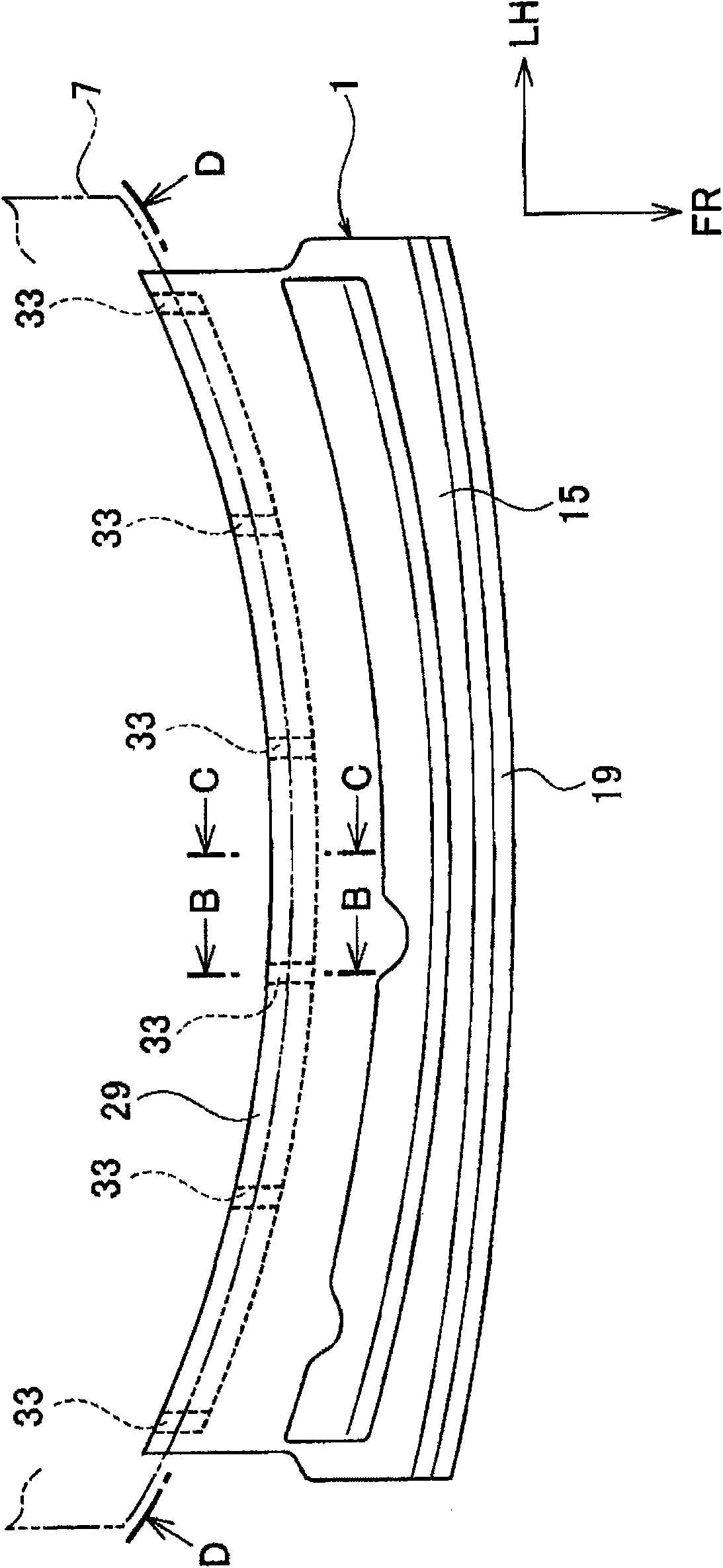

[0076] Embodiments of the present invention will be described below based on the drawings.

[0077] figure 1 yes figure 2 The A-A sectional view of FIG. 1 shows the installation structure of the cowl top according to the first embodiment of the present invention. In each drawing described below, the direction indicated by the arrow FR is the front of the vehicle, the direction indicated by the arrow UP is the upper side of the vehicle, and the direction indicated by the arrow LH is the left side of the vehicle.

[0078] The cowl top 1 is integrally formed of synthetic resin, is located between the cover 5 covering the upper opening of the engine room 3 and the front windshield panel 7, extends along the vehicle width direction, and covers the front windshield functioning as an air box. Surround the upper opening of upper panel 9. In the cowl top panel 9, the vehicle rear end portion 9a is attached to the partition plate 13 for separating the engine room 3 from the vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com