Modified structure of battery integral installation jig

A fixture and battery technology, applied in the direction of lead-acid batteries, lead-acid battery construction, auxiliary devices, etc., can solve the problems of fast wear of fixtures, low service life, time-consuming, etc., to improve work efficiency, improve service life, overall structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

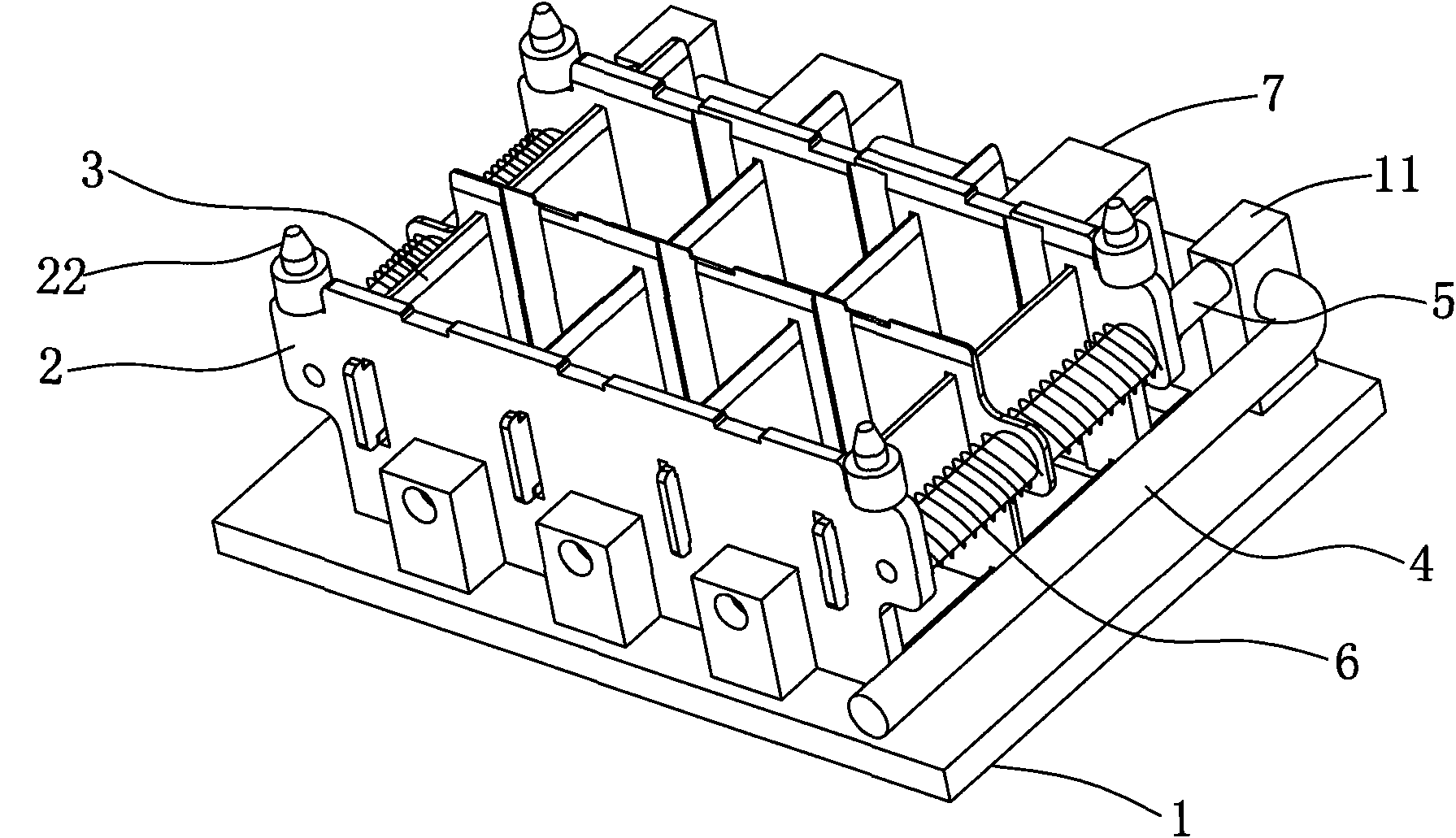

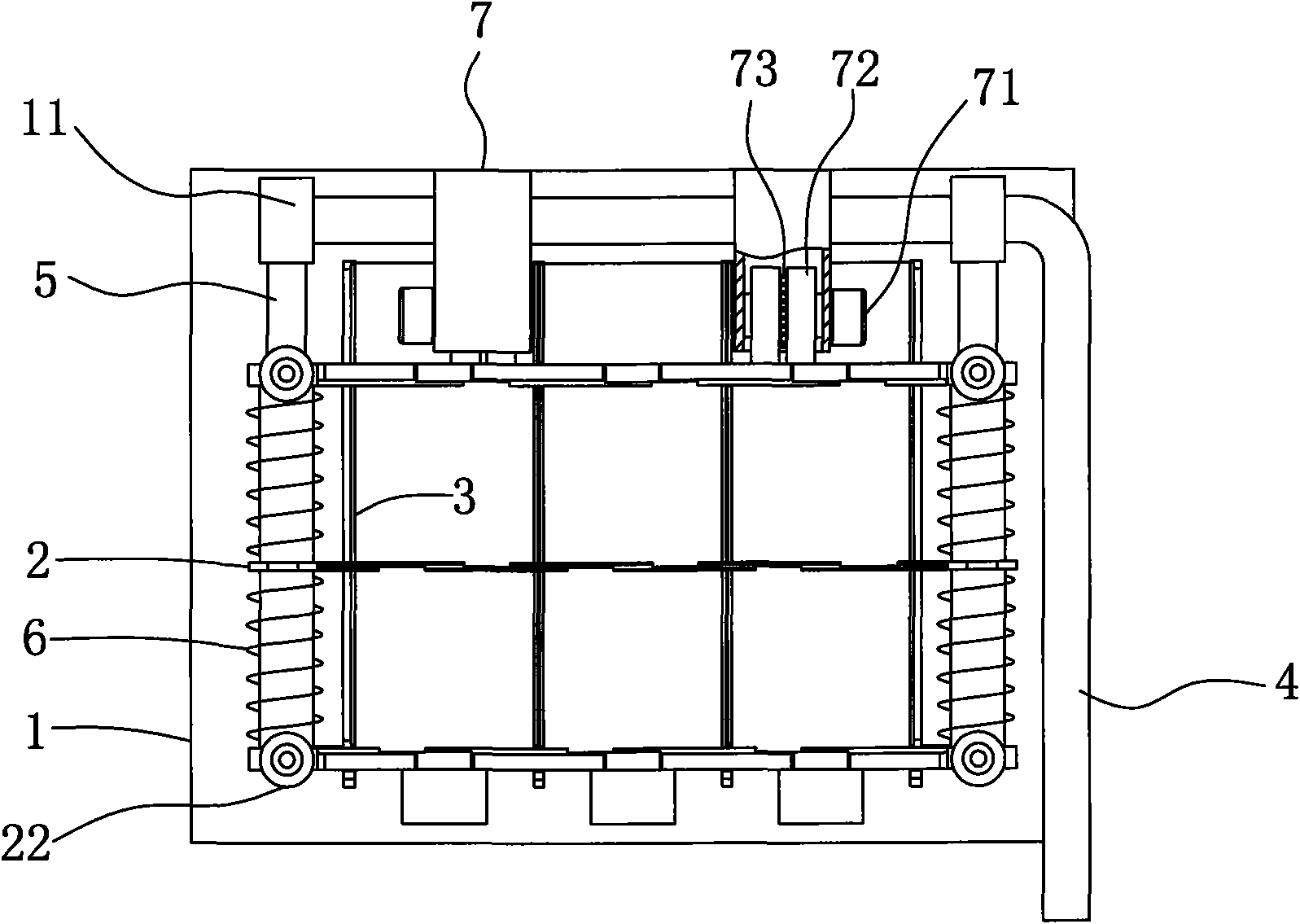

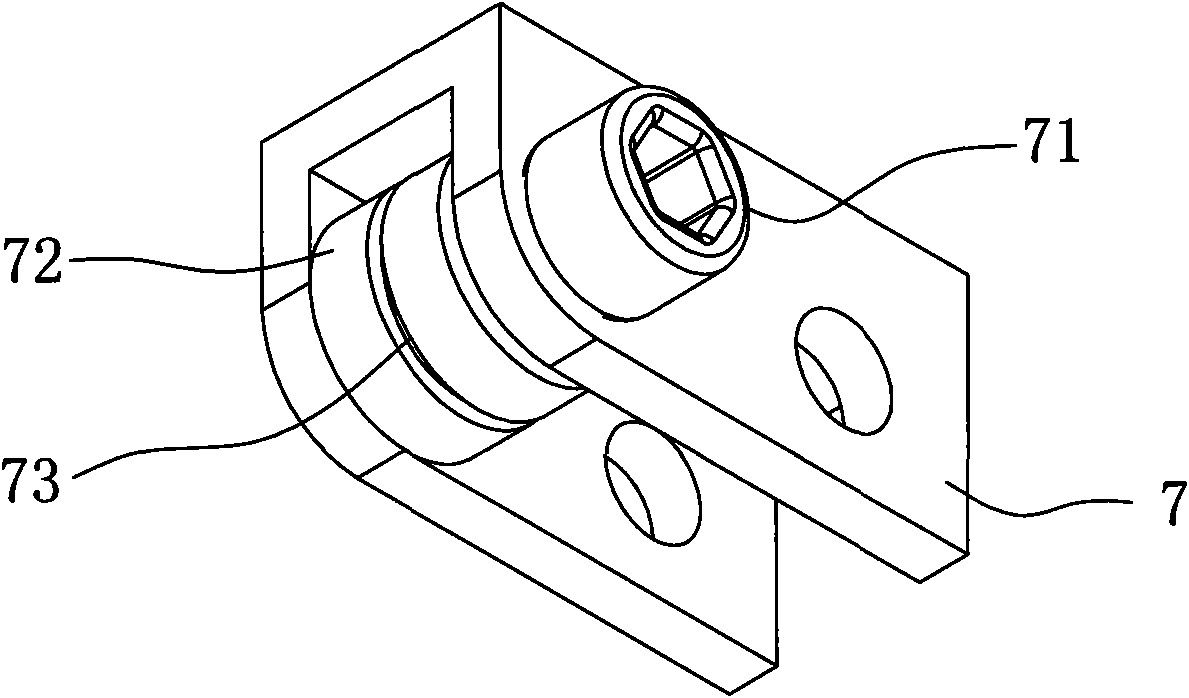

[0017] Such as figure 1 , figure 2 As shown, the present invention is an improved structure of a battery assembly fixture, including a bottom plate 1, on which a movable frame composed of several splints and a clamping mechanism for tightening the movable frame are installed. The tightening mechanism is provided with a rolling chuck acting on the splint. The rolling chuck greatly reduces the friction between the clamping mechanism and the splint, which improves the service life of the clamp.

[0018] The movable frame is composed of several parallel fixed splints 3 and movable splints 2 arranged in a staggered manner. The movable splint 2 is provided with a chute 23, the fixed splint 3 is installed in the chute 23, and the rolling chuck acts on the movable splint. 2 on. The clamping mechanism includes several pads 11 arranged side by side on one side of the base plate 1, the L-shaped handle 4 is flexibly connected to the pads 11, and the L-shaped handle 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com