Method for generating air cushion by heavy-duty ship and heavy-duty hovercraft thereof

A technology of air cushions and ships, which is applied in the direction of hull, hull design, ship construction, etc., to achieve the effect of fast speed and reduced frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

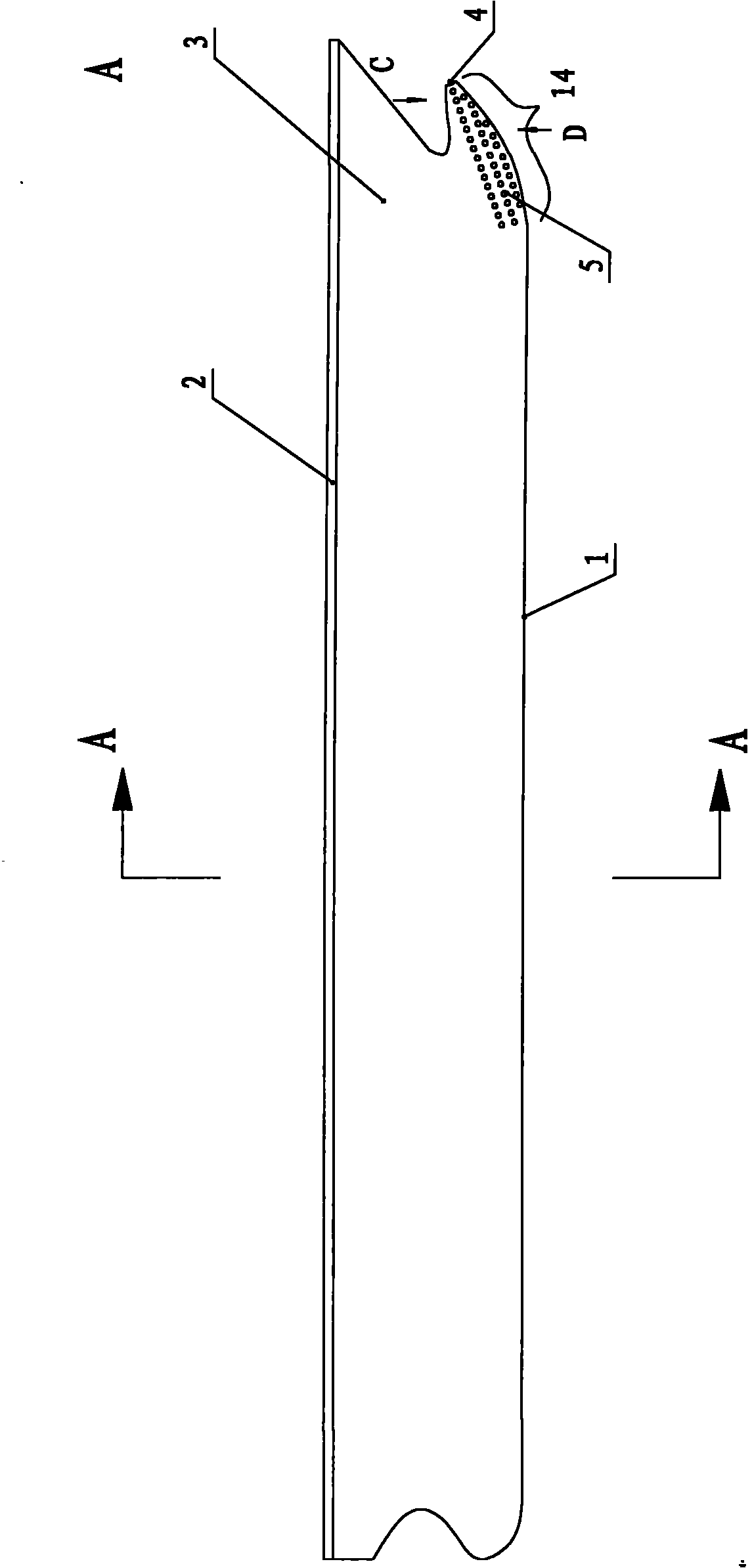

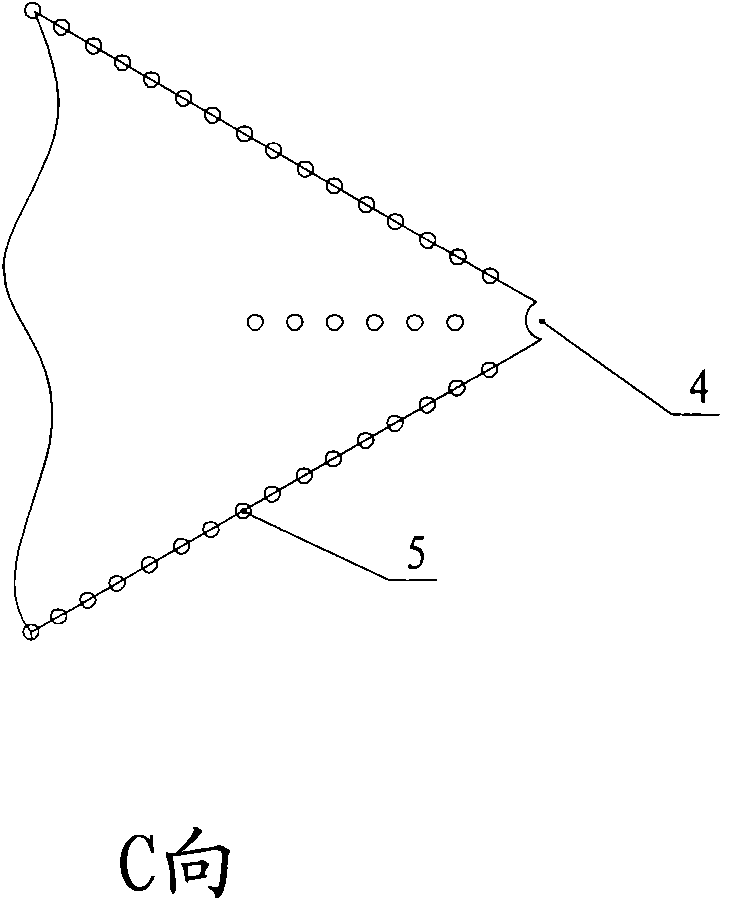

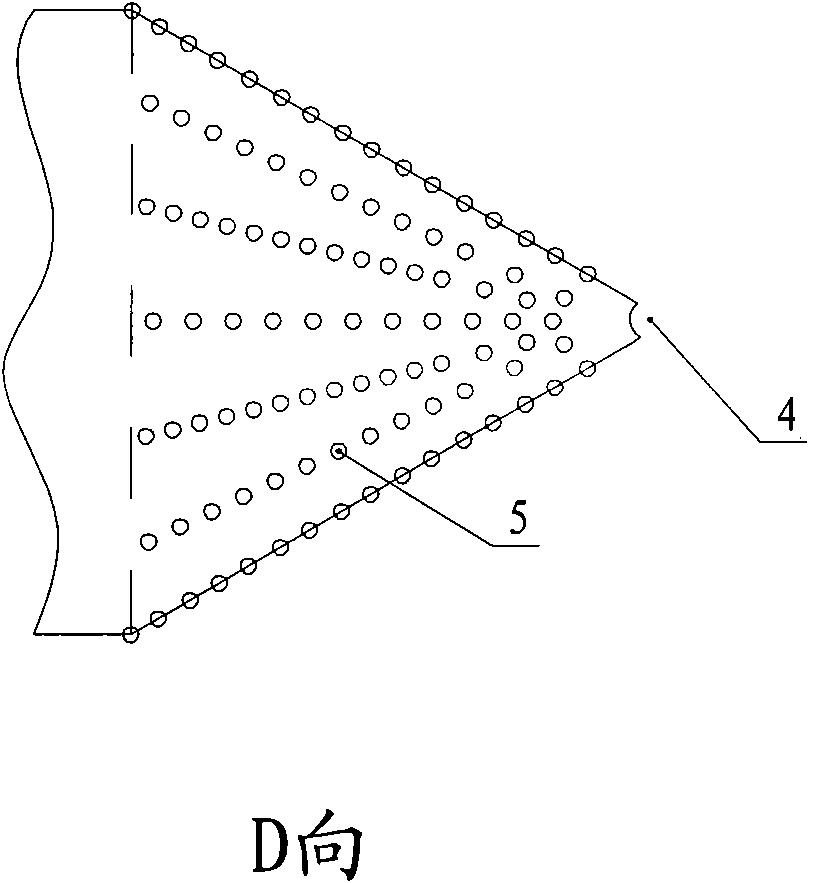

[0024] Embodiment one: see Figure 1-Figure 4 , Image 6 , a heavy-duty air-cushion ship in the figure, including a hull. The hull is equipped with an air compressor unit, a high-pressure gas storage tank, and an air supply pipeline, and is also equipped with a power propulsion unit, a transmission mechanism, a propeller unit, and a generator unit. The jet holes evenly distributed on the flat part of the bottom of the ship, each jet hole is connected with the air supply pipeline; Each jet hole is connected respectively, and a check valve is installed on the jet pipeline, and a pressure reducer is installed on the jet pipeline; the jet hole is set at the water diversion part of the bow as the center jet hole, and the diameter of the center jet hole is maximum.

[0025] The upper surface of the bow is provided with a row of jet holes backward from the center jet hole; the two sides of the bow and the bottom surface of the bow are provided with a central jet hole extending from...

Embodiment 2

[0027] Embodiment two: see Figure 1-Figure 3 , Figure 5 , Image 6 , a heavy-duty air-cushion ship in the figure, including a hull. The hull is equipped with an air compressor unit, a high-pressure gas storage tank, and an air supply pipeline, and is also equipped with a power propulsion unit, a transmission mechanism, a propeller unit, and a generator unit. The jet holes evenly distributed on the flat part of the bottom of the ship, each jet hole is connected with the air supply pipeline; Each jet hole is connected respectively, and a check valve is installed on the jet pipeline, and a pressure reducer is installed on the jet pipeline; the jet hole is set at the water diversion part of the bow as the center jet hole, and the diameter of the center jet hole is maximum.

[0028] The upper surface of the bow is provided with a row of jet holes backward from the center jet hole; the two sides of the bow and the bottom surface of the bow are provided with a central jet hole e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com