Gravity center measurement instrument of propeller blade with variable screw pitch

A propeller and variable pitch technology, which is applied in the field of measuring instruments for the center of gravity of propeller blades of adjustable pitch propellers, can solve the problems of increasing instrument cost, affecting measurement accuracy, and complex structure, so as to reduce the number of guide rails and position detection equipment and prevent sideslip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

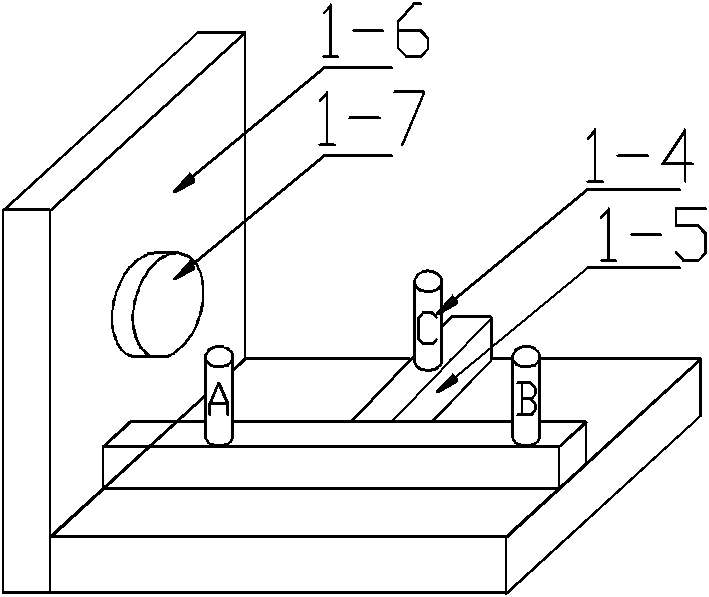

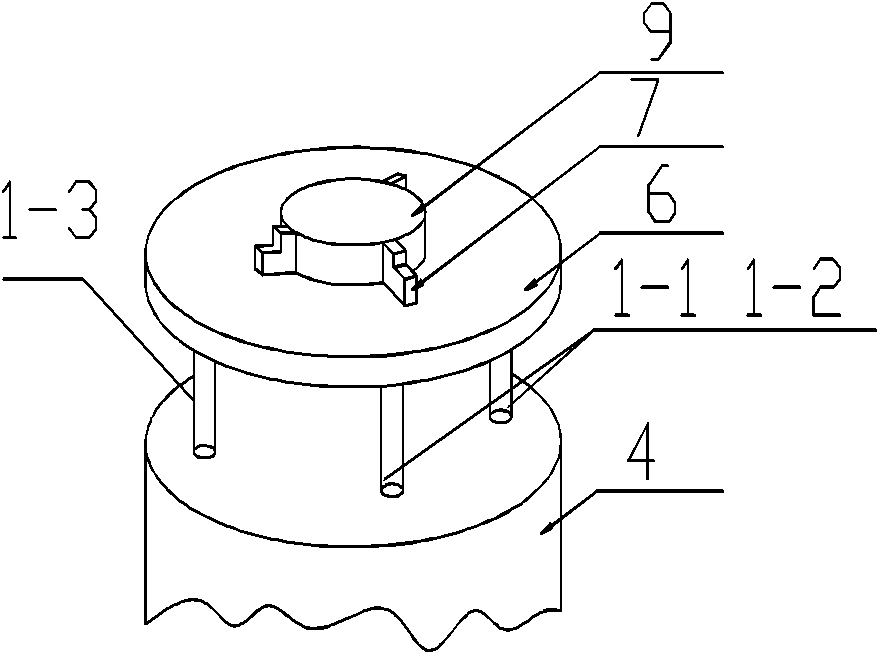

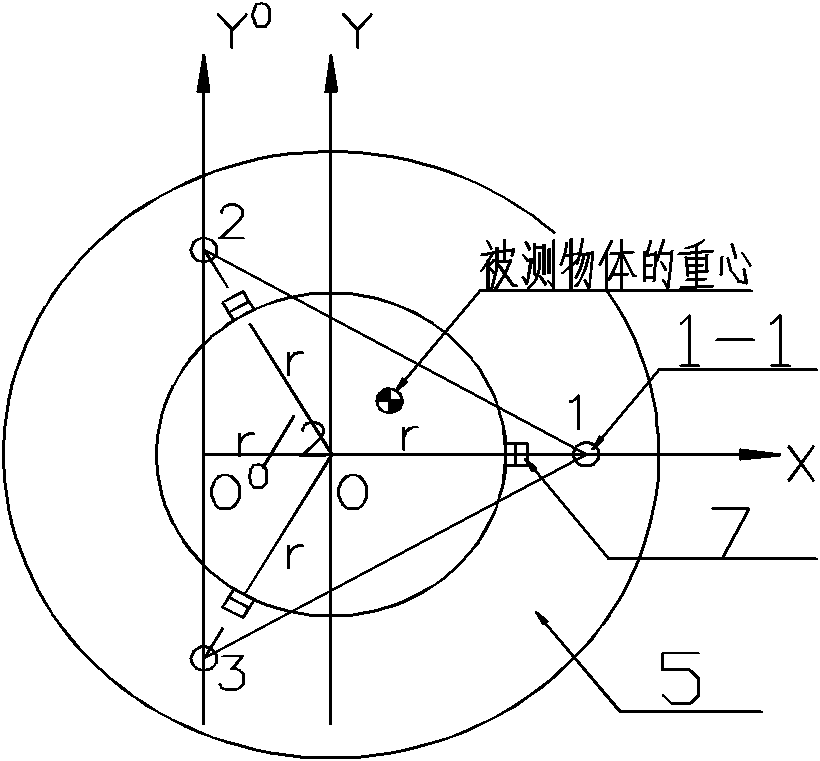

[0022] The variable pitch propeller blade center of gravity measuring instrument of the present invention as shown in the accompanying drawing, it comprises base 4, three pressure transducers 1-1,1-2,1-3 and chuck 5, described three pressure transducers They are symmetrically installed between the bottom surface of the chuck and the top surface of the base along the same circumferential direction, and the center of the circle formed by the three sensors is located on the central axis of the chuck, and one connected to the controller The sensor can move up and down through the lifting system. Said controller is connected to one of the three sensors for displaying the reading of the connected sensor.

[0023] The lifting system can adopt a variety of existing structures, such as: the lifting system can include a screw nut structure, the nut in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com