Eccentric worm pump with split stator

An eccentric screw pump and stator technology, applied to pumps, mechanical equipment, rotary piston pumps, etc., can solve the troublesome problems of plug-in stators, and achieve the effect of simple manufacture, simple installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

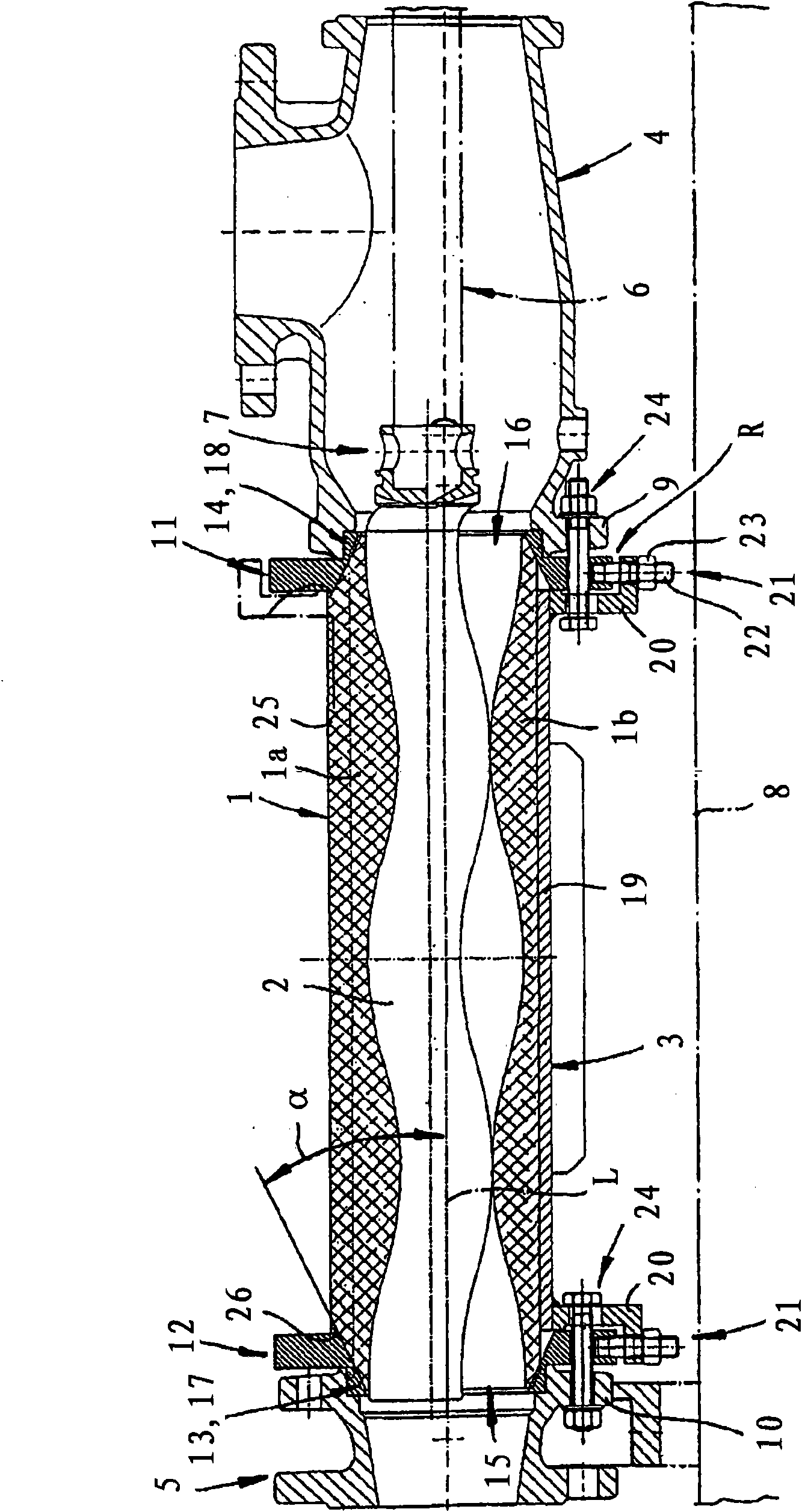

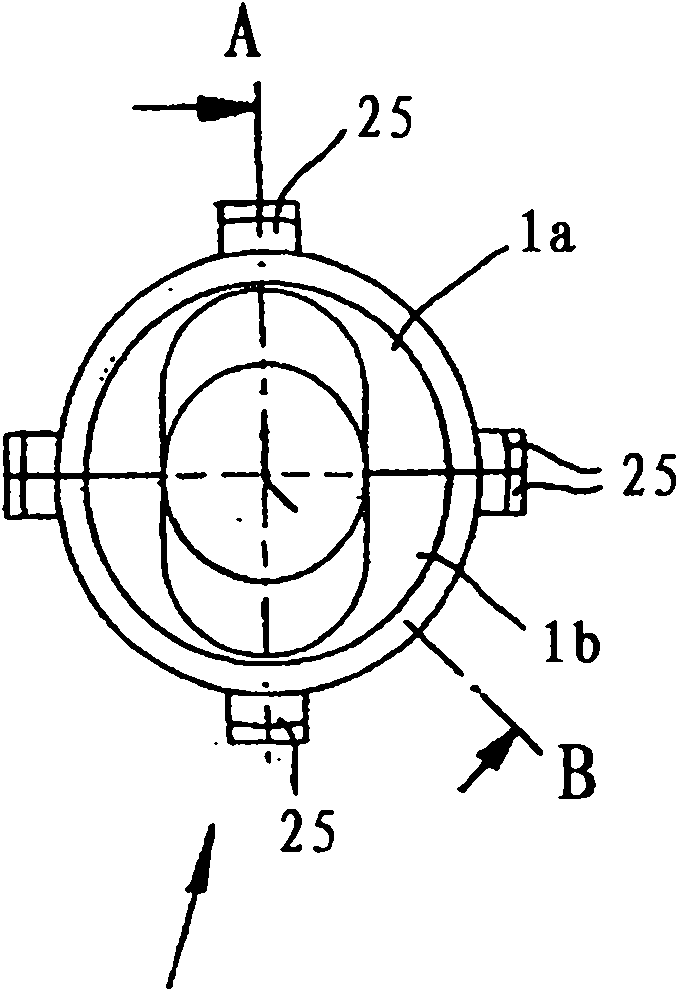

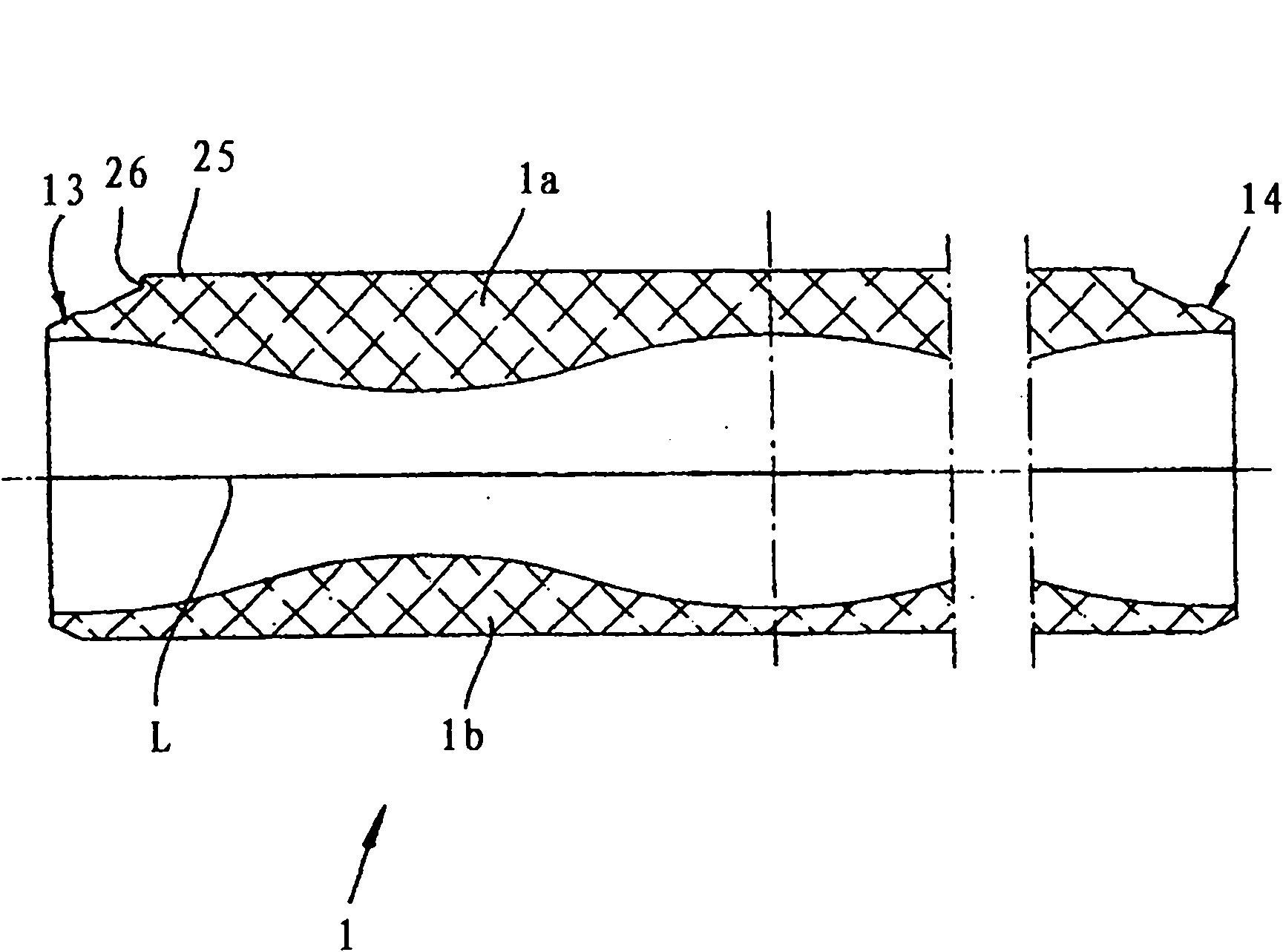

[0026] The drawing shows an eccentric screw pump, which in its basic construction has a stator 1 made of elastic material and a rotor 2 mounted in the stator 1, wherein the stator 1 is at least partially Surrounded by a stator sleeve 3 . In addition, the above-mentioned pump has a suction housing 4 and a connecting line 5, which is also called a pressure line. Not shown is a similarly arranged drive, wherein the drive is via a connecting rod, which is only briefly shown. 6 works on rotor 2. The connecting rod is connected via a joint shaft on the one hand to the rotor 2 and on the other hand to a drive shaft (not shown), wherein only the rotor-side hinge 7 is shown on the joint shaft. The above-mentioned pumps are usually mounted on a base 8 which is only schematically shown, wherein in this context it can be a base 8 supplied with the pump or also a base present on the application side. The stator 1 is connected via its one end to the connecting flange 9 of the suction hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com