Fuel cell system

一种燃料电池系统、燃料电池的技术,应用在燃料电池、燃料电池助剂、运输燃料电池技术等方向,能够解决蓄电池过度充电等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

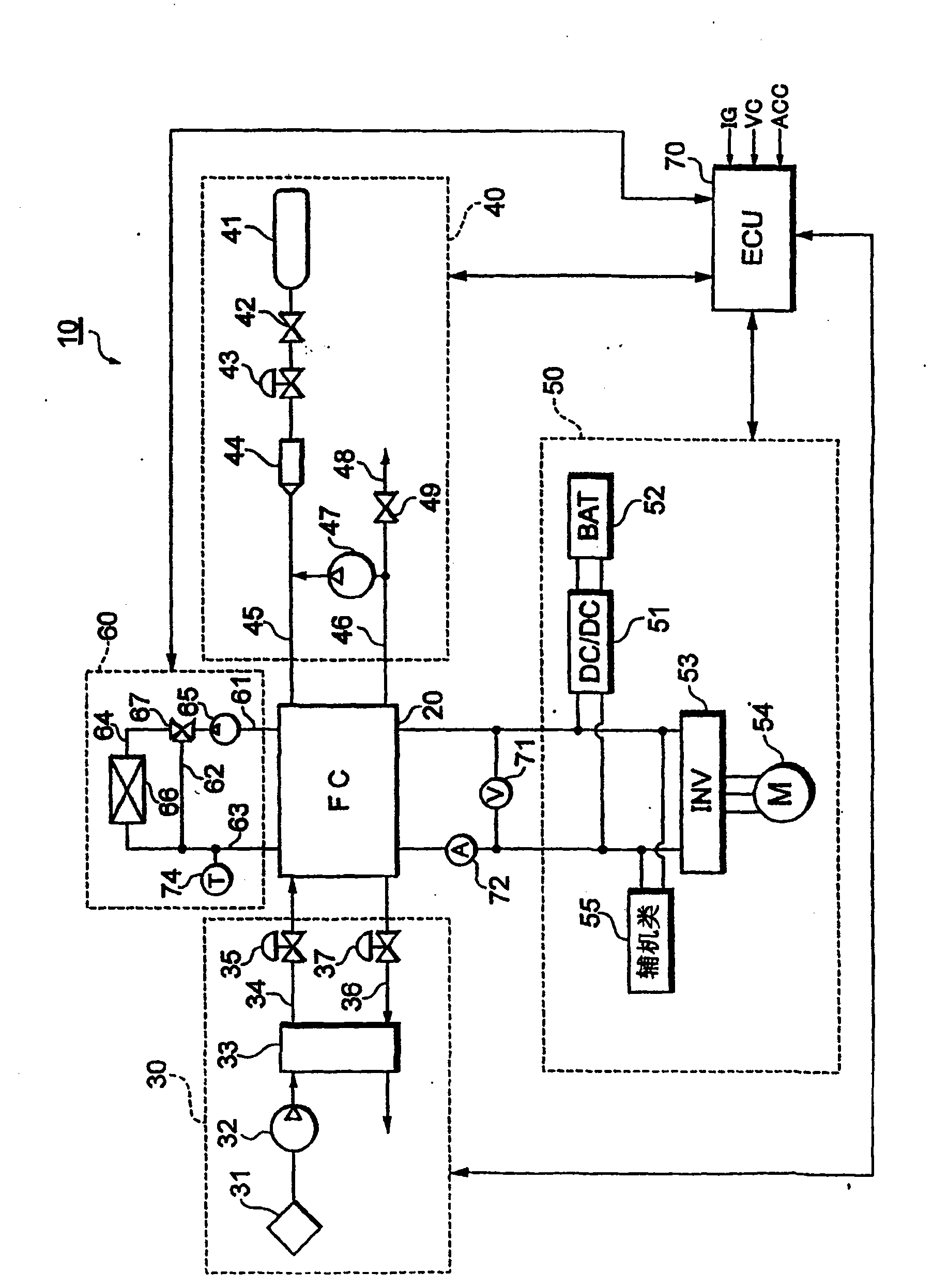

[0032] figure 1 The system configuration of the fuel cell system 10 of this embodiment is shown.

[0033] The fuel cell system 10 functions as an on-board power supply system mounted on a fuel cell vehicle, and includes a fuel cell stack 20 that receives supply of reactive gas (fuel gas, oxidizing gas) to generate power, and supplies the fuel cell stack 20 as an oxidizer. An oxidizing gas supply system 30 for gaseous air, a fuel gas supply system 40 for supplying hydrogen as a fuel gas to the fuel cell stack 20, a power system 50 for controlling the charge and discharge of power, and a power system for controlling the fuel cell stack 20 A cooling system 60 for cooling, and a control unit (ECU) 70 that controls the entire system.

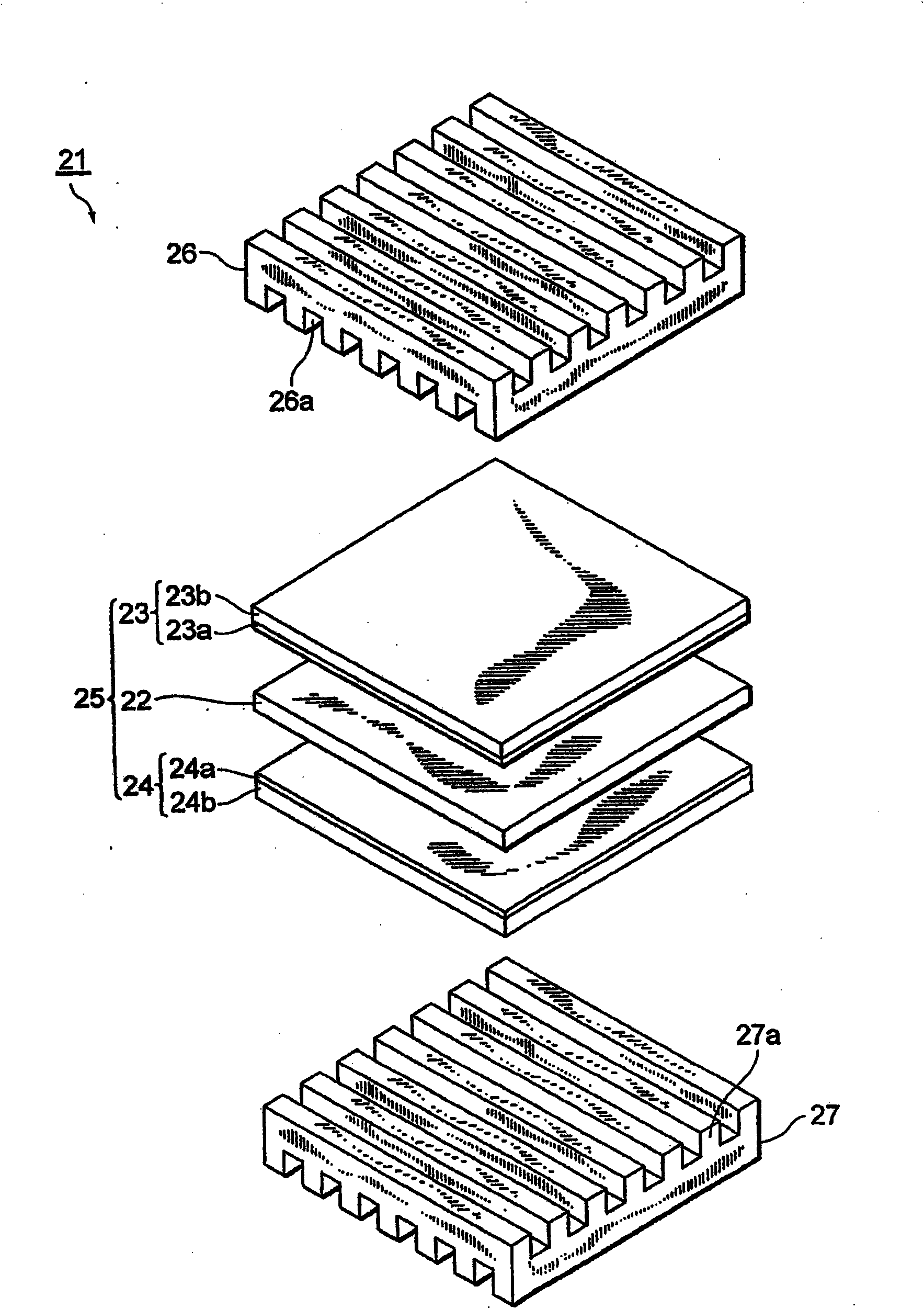

[0034] The fuel cell stack 20 is a solid polymer electrolyte battery stack in which a plurality of unit cells are stacked in series. In the fuel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com