Centrifugal preparation method of electrolyte thin film of solid oxide fuel cell

A technology of electrolyte film and solid oxide, which is applied in the field of preparation of solid oxide fuel cell electrolyte film, can solve problems such as easy cracking, influence of operating environment, complex process, etc., and achieve convenient operation, good consistency and good uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

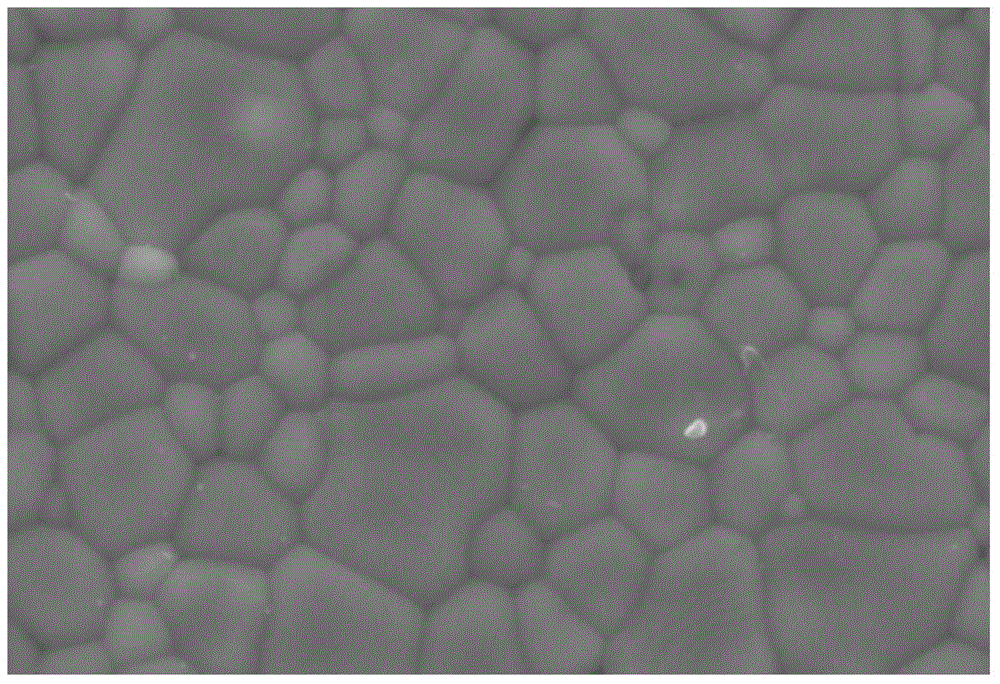

[0030] ①Measure 100mL of absolute ethanol as solvent, add 2gSm 0.2 Ce 0.8 o 1.9 (SDC) electrolyte powder, put into the planetary ball mill with 200r / min ball mill for 24h, then add 0.5% polyethylene glycol (PEG) auxiliary agent and continue to mix and mill for 10h to obtain uniform and stable SDC slurry, ready for use;

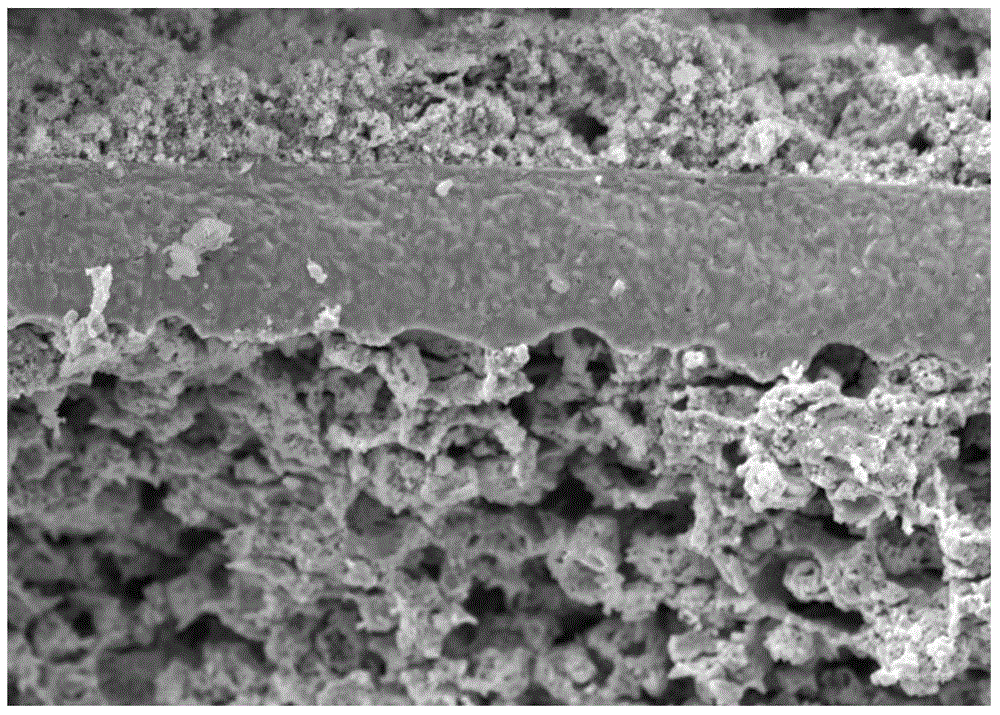

[0031] ②The anode support body of NiO-SDC was prepared by dry pressing method, and it was calcined at high temperature to be ready for use;

[0032] ③ Bond one side of the NiO-SDC anode support in the above step ② with scotch tape and fix it on an anode support platform, then put the platform into a centrifuge tube and place it in a clean centrifuge tube. The good SDC slurry is slowly injected into the centrifuge tube until the NiO-SDC anode support is completely submerged;

[0033] ④Then put the centrifuge tube prepared in the above ③ into the centrifuge, turn on the centrifuge, make it run at a speed of 3999r / min for 10min, and form a layer of SDC electro...

Embodiment 2

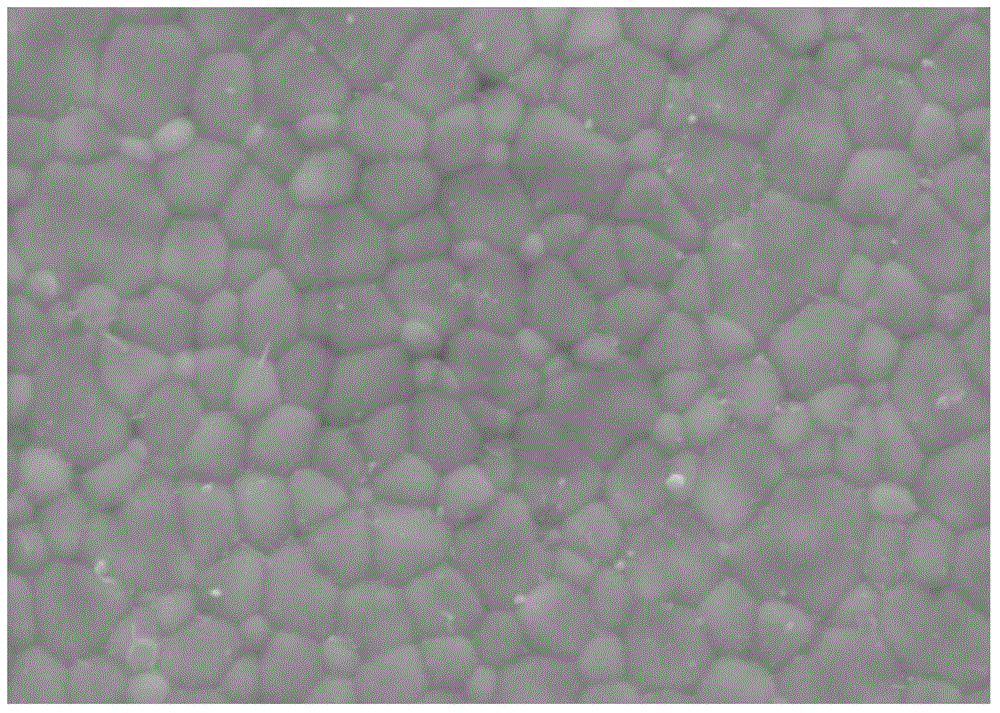

[0038] ①Measure 100mL of absolute ethanol as solvent, add 2gSm 0.2 Ce 0.8 o 1.9 (SDC) electrolyte powder, put into the planetary ball mill with 200r / min ball mill for 24h, then add 0.5% polyethylene glycol (PEG) auxiliary agent and continue to mix and mill for 10h to obtain uniform and stable SDC slurry, ready for use;

[0039] ②The anode support body of NiO-SDC was prepared by dry pressing method, and it was calcined at high temperature to be ready for use;

[0040] ③ Bond one side of the NiO-SDC anode support in the above step ② with scotch tape and fix it on an anode support platform, then put the platform into a centrifuge tube and place it in a clean centrifuge tube. The good SDC slurry is slowly injected into the centrifuge tube until the NiO-SDC anode support is completely submerged;

[0041] ④Then put the centrifuge tube prepared in the above ③ into the centrifuge, turn on the centrifuge, make it run at a speed of 3999r / min for 10min, and form a layer of SDC electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com