Electric machine and rotor arrangement

A technology for rotors and synchronous motors, applied in electromechanical devices, electrical components, electrical components, etc., to solve problems such as unknown offsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The same reference numerals in the following embodiments represent elements with the same or similar functions.

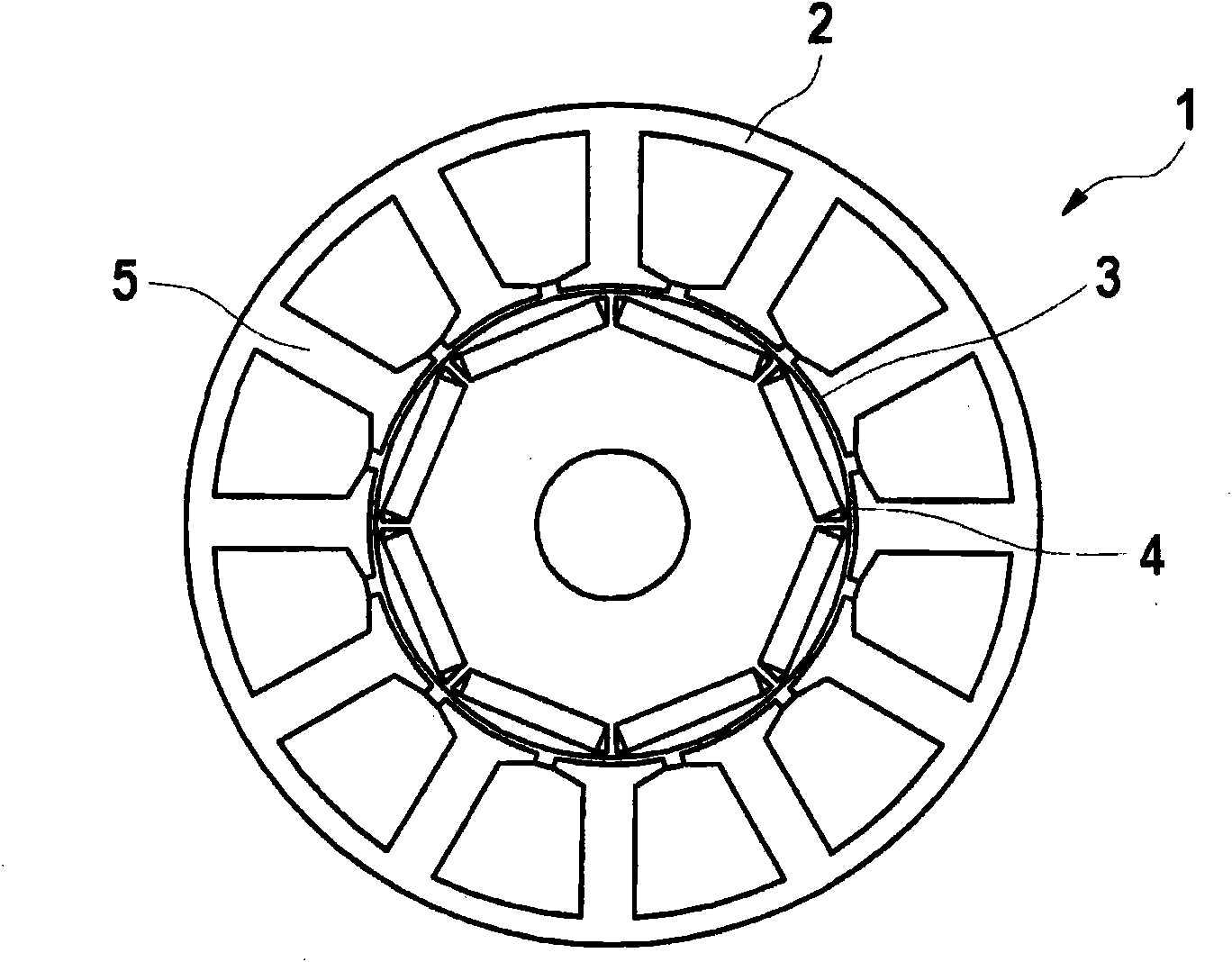

[0029] figure 1 Shown is a schematic cross-sectional view of an electric machine, in particular a permanently excited synchronous machine 1 , with a stator arrangement 2 with a stator interior 3 therein. A rotor device 4 rotatable about an axis is mounted in the stator inner chamber 3 . The stator arrangement 2 has stator teeth 5 pointing towards the rotor arrangement 4 (inwardly), all or part of which are wound by (not shown in the figure) stator coils. The stator teeth 5 widen towards the stator interior 3 and each have a contour in the shape of a circular arc segment, which defines the majority of the inner surface of the stator contour 3 . The stator arrangement 2 is preferably formed in the axial direction (the axial direction of the stator arrangement) from a preferably stamped sheet metal, so that the stator arrangement 2 in the form of a laminated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com