Fiber-reinforced composite casing pipe

A composite material, fiber-reinforced technology, applied in construction, drinking water installations, water supply installations, etc., can solve the problems of breakage, short service life, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

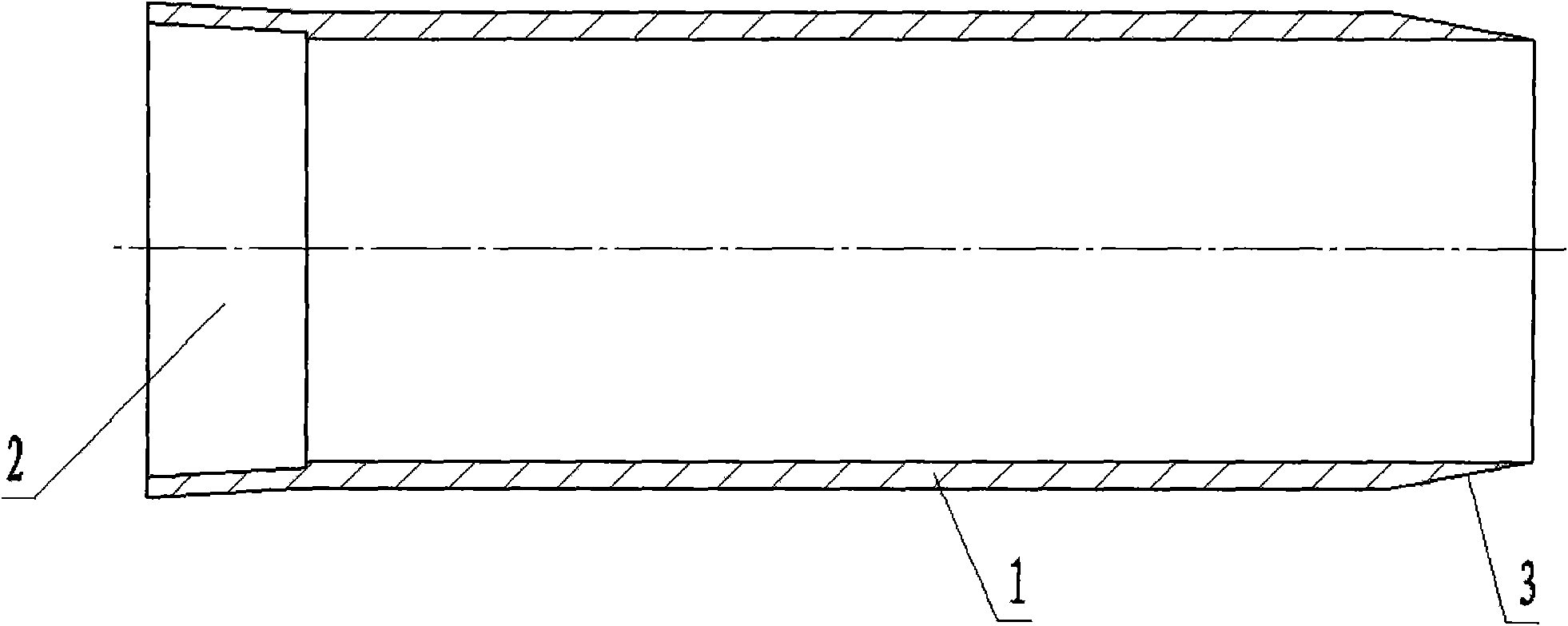

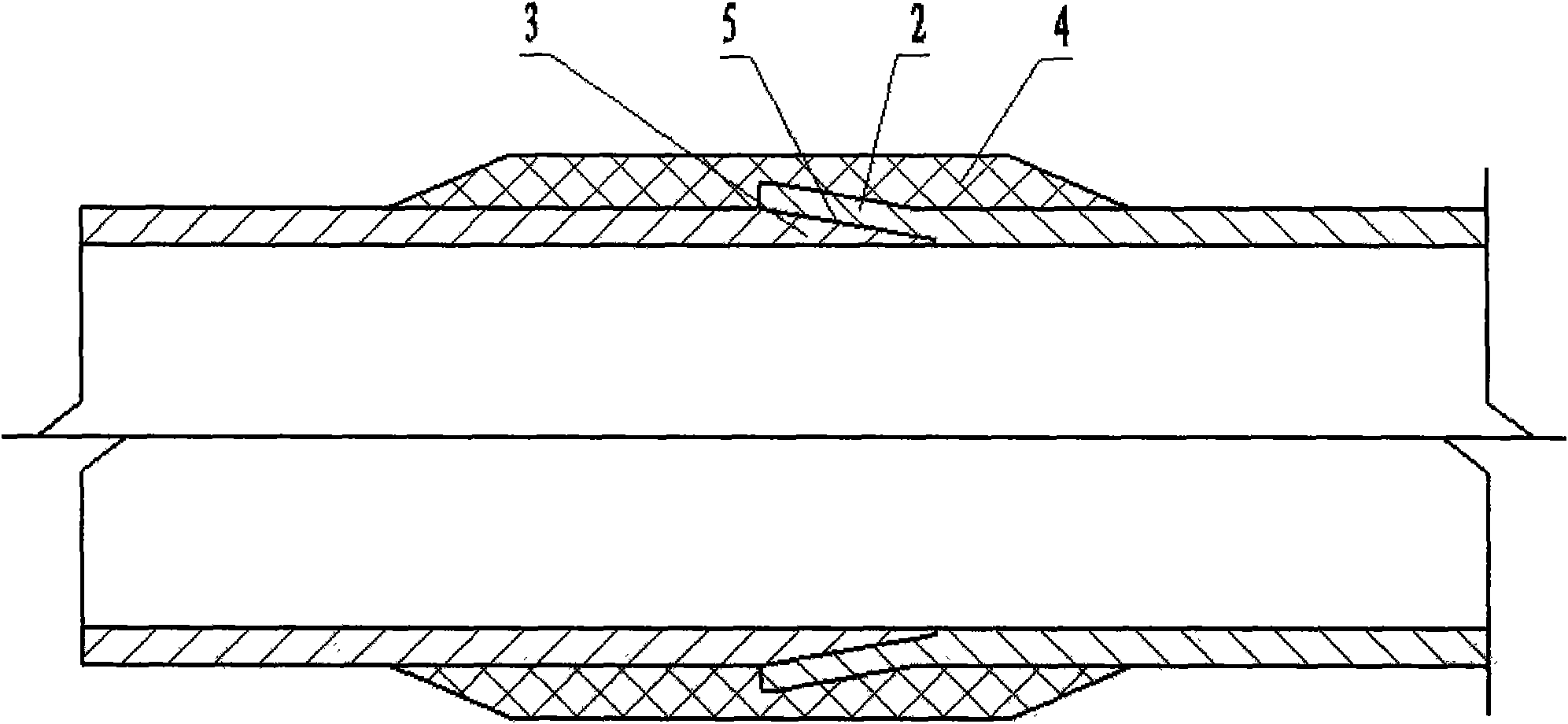

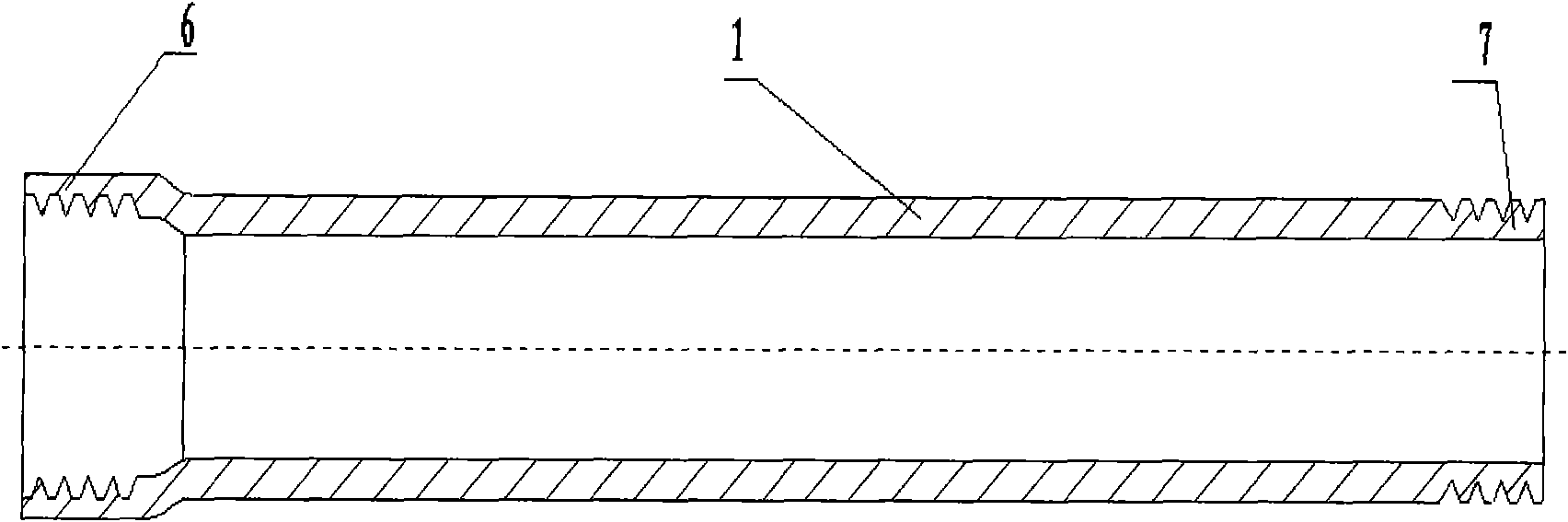

[0009] see Figure 1 to Figure 2 , the pipe body 1 of the present invention is based on jelly, various fibers are reinforcing materials, and a kind of pipe resin composed of inorganic particles as fillers. The pipe wall structure from inside to outside is respectively: inner lining layer, Inner reinforcement layer, stiffness layer, outer reinforcement layer, outer protection layer. The pipe is connected by socket glue or thread, that is, the two ends of the pipe body 1 are respectively provided with a socket 2 or an internal thread 6 and a socket 3 or an external thread 7 that match each other, and the two are glued together or reversed to each other when connecting. Rotate, and use fiber material 4 on the outside of the connection 5 to carry out manual paste connection, and the joint connection is fastened and reliable. These connection methods ensure the concentricity of the entire well pipe during the running process, and have high mechanical strength, simple operation, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com