Method for preparing epitaxial composite substrate of gallium nitride based semiconducting material

A composite substrate, gallium nitride-based technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost and high lattice mismatch, and achieve low cost, close thermal expansion coefficient, and favorable The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

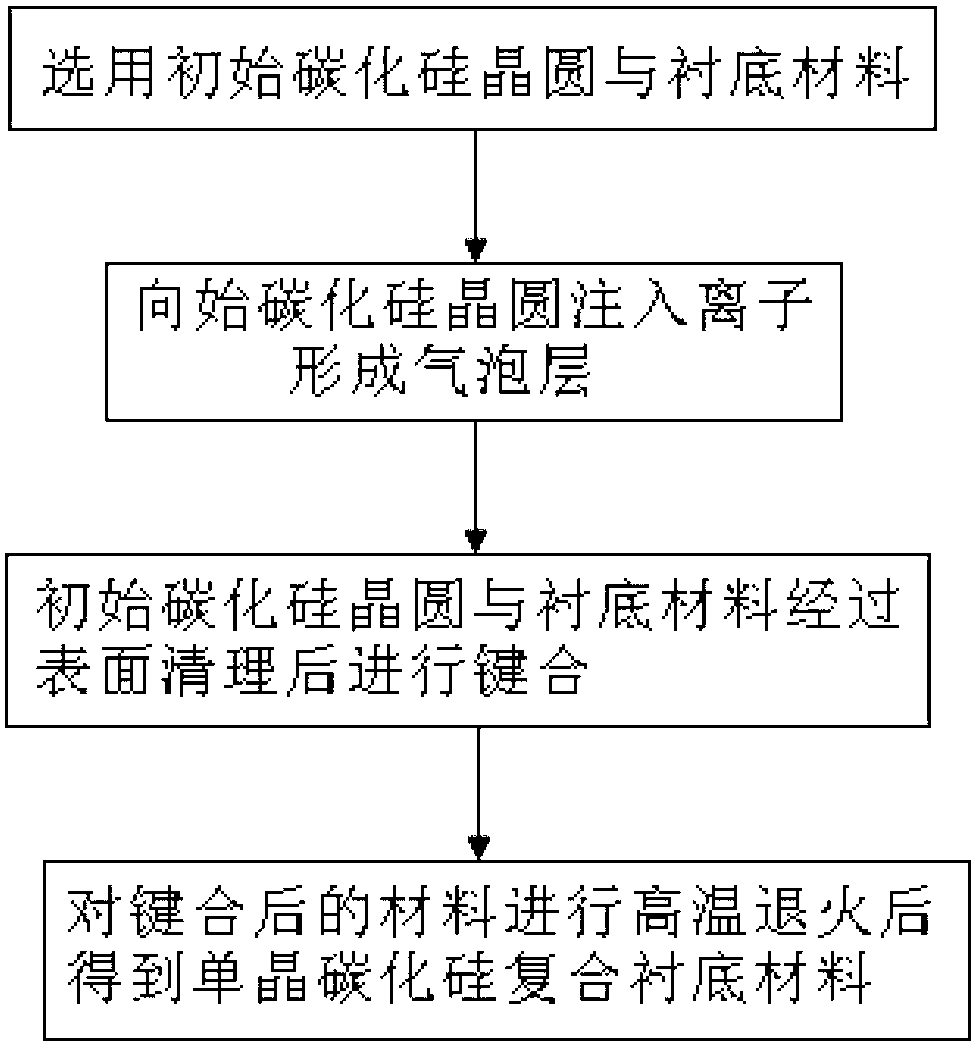

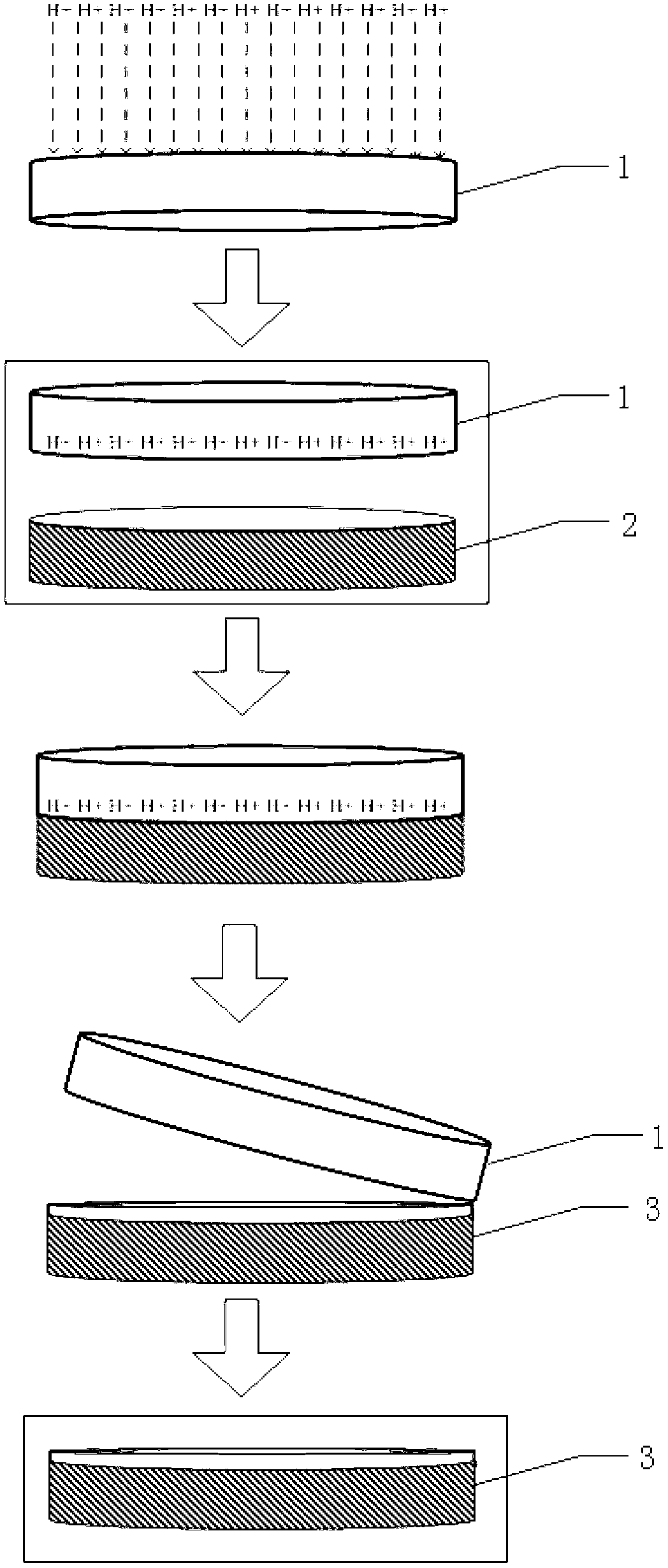

[0026] The preparation method of the GaN-based semiconductor material epitaxial composite substrate of the present invention, such as figure 2 shown, including:

[0027] Step 1: Select an initial single crystal silicon carbide (SiC) wafer 1 and a substrate material 2; the initial single crystal silicon carbide wafer 1 is a 4H or 6H phase single crystal silicon carbide with a diameter of 1 to 6 inches and a thickness of 0.1 to 0.8 mm. The substrate material 2 is a single crystal silicon or polycrystalline silicon wafer with a diameter of 1 to 6 inches, or a disk made of sintered nitride / oxide ceramic powder, with a thickness of 0.2 mm to 1 mm. Nitride ceramic powders include boron nitride and aluminum nitride; oxide ceramic powders include aluminum oxide.

[0028] Step 2: Ion implantation of the hydrogen injection intelligent peeling method, the implantation is hydrogen ions, helium ions or co-implantation of both, or co-implantation of boron ions and hydrogen ions; the impl...

Embodiment

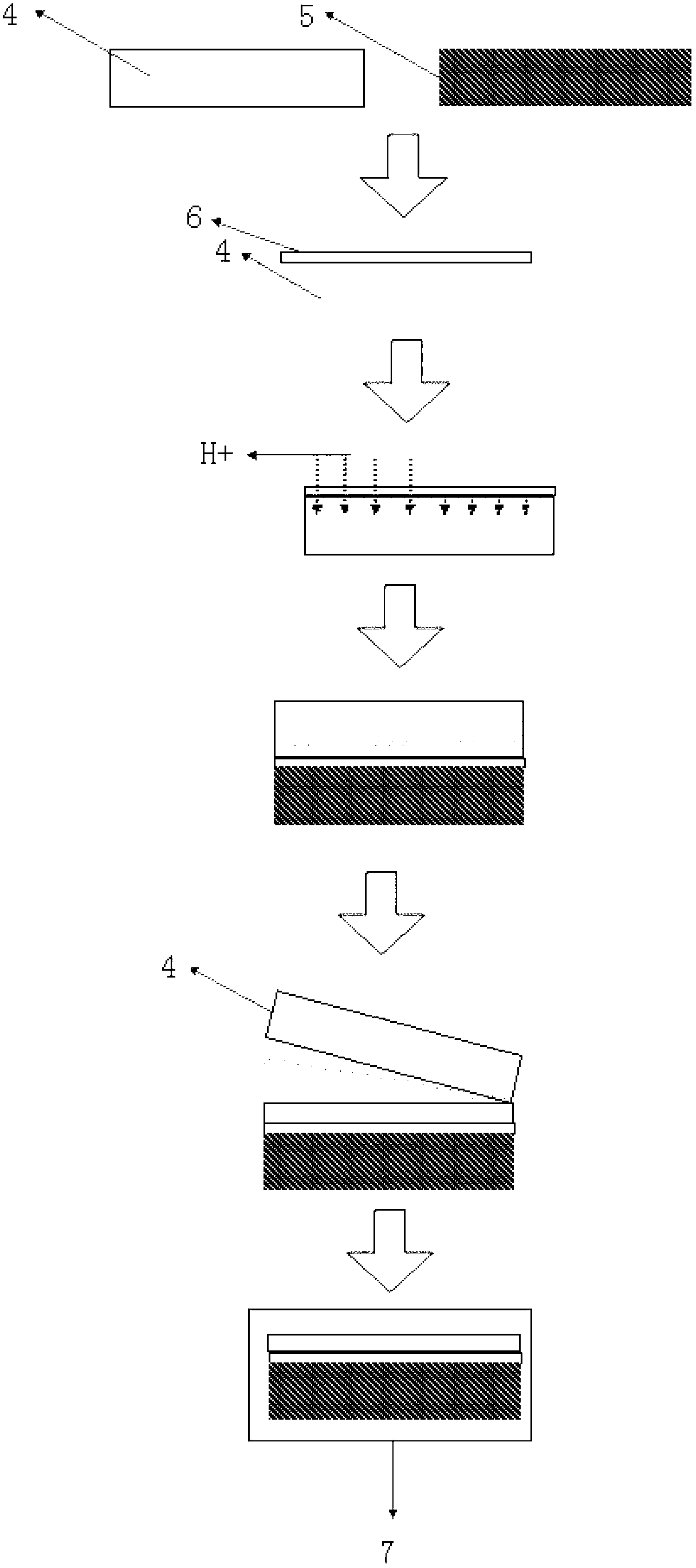

[0035] In this embodiment, the process of preparing a gallium nitride-based semiconductor material epitaxial composite substrate includes the following steps, such as image 3 Shown:

[0036] Step 1: Select an initial SiC wafer 1 and a substrate material 2 . The initial SiC wafer 1 is single crystal SiC with a diameter of 1-6 inches in 4H or 6H phase and a thickness of 0.1-0.8 mm. The substrate material 2 is a single crystal Si or polycrystalline Si wafer with a diameter of 1-6 inches, or a disk made of nitride / oxide ceramic powder sintered, with a thickness of 0.2mm-1mm.

[0037] Step 2: Ion implantation of hydrogen injection intelligent stripping method, the implantation is hydrogen ion, helium ion or co-implantation of both, or B ion and hydrogen ion co-implantation; the implantation energy is 5keV-1000keV, and the implantation dose is 1E15-1E18cm -2 , the implantation temperature is room temperature, and the implanted ions form a bubble layer in the initial SiC wafer 1 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com