Flexible end effector for cone picking robot

A picking robot and end effector technology, applied in picking machines, manipulators, harvesters, etc., can solve problems such as poor shape adaptability of fruits, and achieve the effect of good shape adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] With reference to accompanying drawing, further illustrate the present invention:

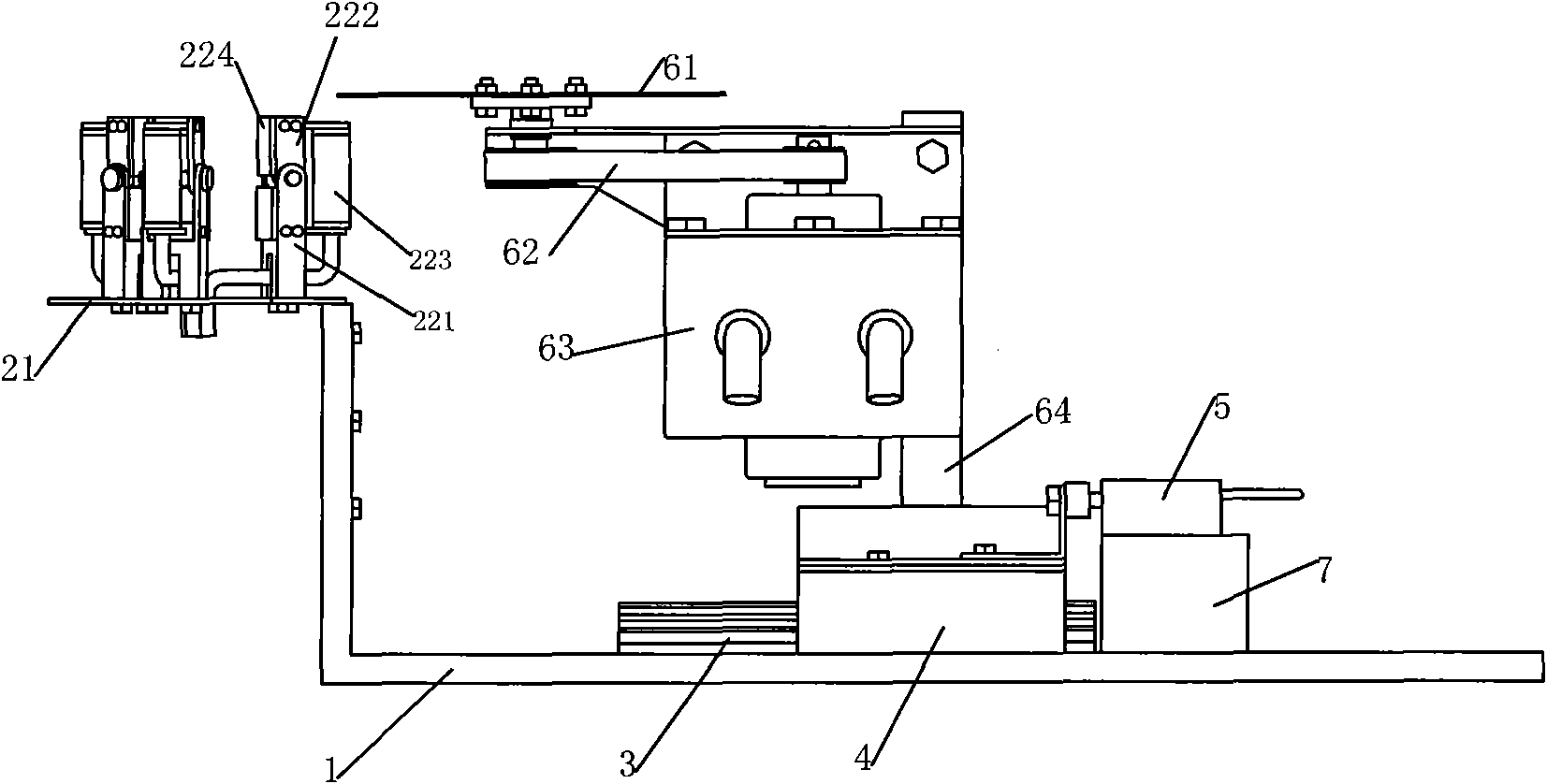

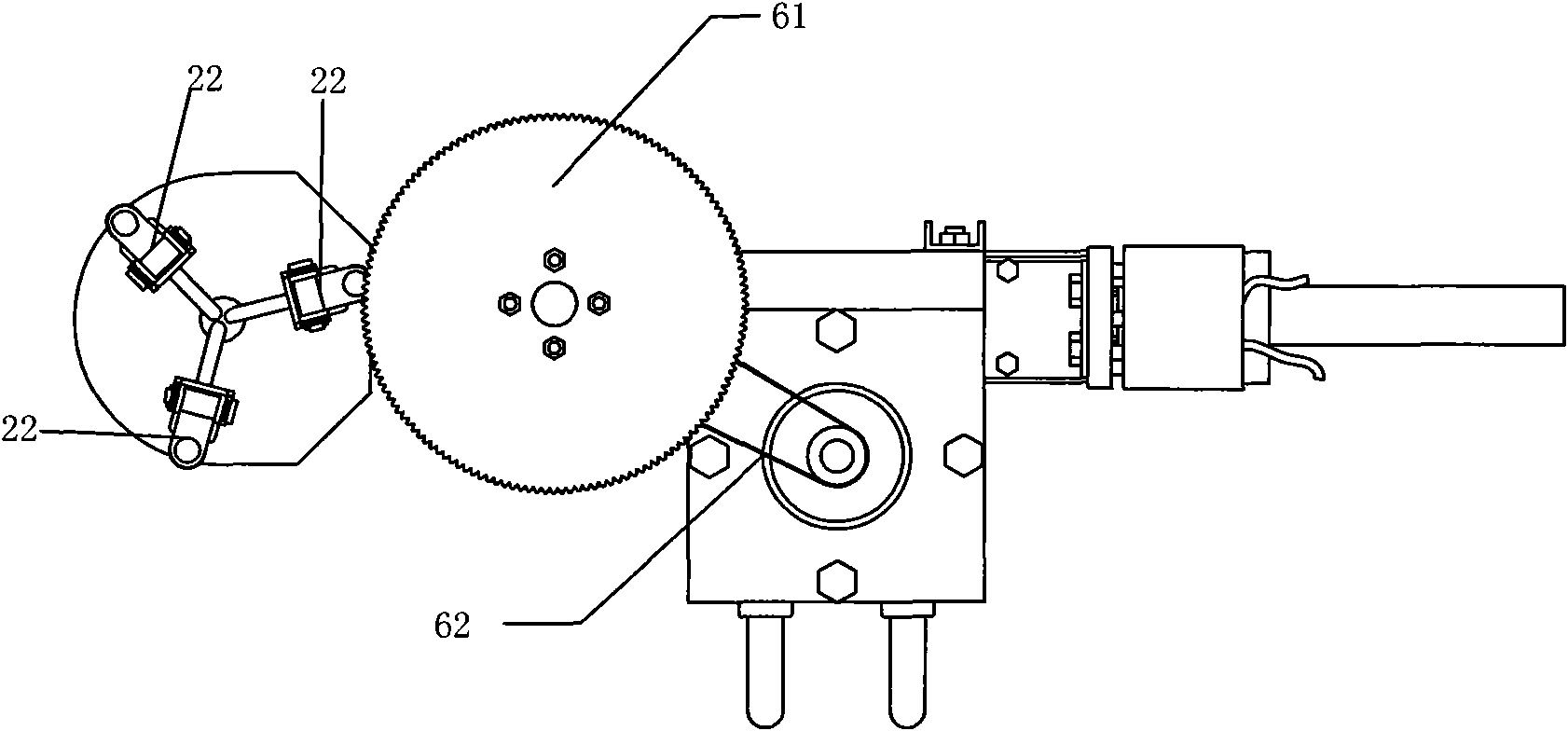

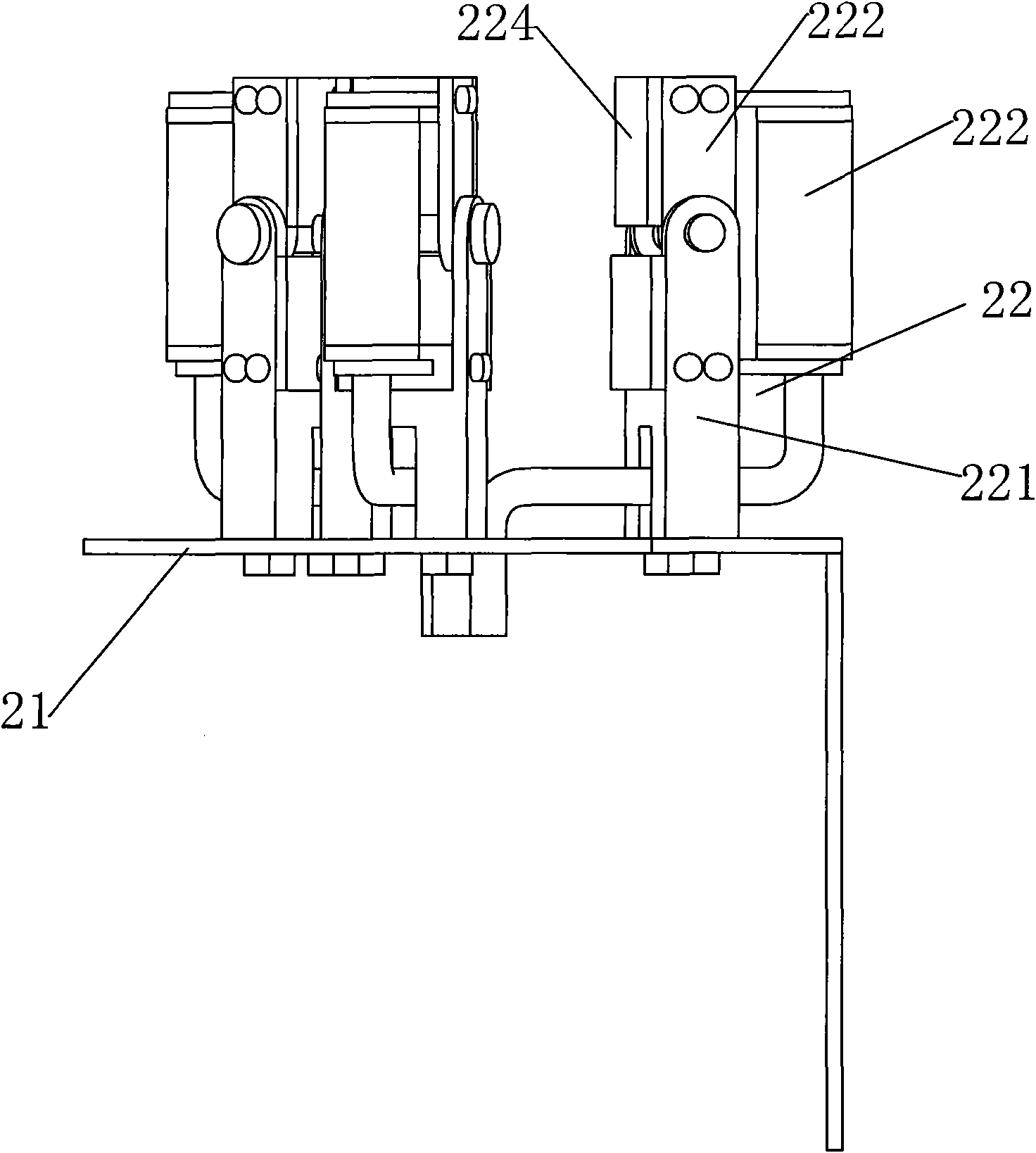

[0019] The flexible end effector of the cone picking robot includes a frame 1, and the frame 1 is provided with a gripper mechanism for grabbing fruits and vegetables, and the gripper mechanism includes a base 21 and fingers 22, and the fingers 22 It includes a fixed rod 221 fixed on the base 21 and a connecting rod 222 hinged to the fixed rod 221. The connecting rod 222 is connected with a rubber tube 223 that pushes it to swing relative to the fixed rod 221. The rubber The top end of the tube 223 is sealed, and the bottom end is connected to an inflation mechanism. The base 21 is provided with at least three fingers 22 .

[0020] The frame 1 is fixed with a guide rail 3, a slider 4 slidably installed on the guide rail 3, a cylinder 5 that pushes the slider 4 to move back and forth along the guide rail 3, and a cutting device that separates the grasped fruits and vegetables from their b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com