Bamboo bicycle frame assembly product and assembling method thereof

An assembly method and bicycle technology, which is applied to bicycle frames, bicycle accessories, transportation and packaging, etc., can solve the problems of manual assembly of bamboo bicycle frames, etc., and achieve the effect of simple and intuitive assembly method and satisfying individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

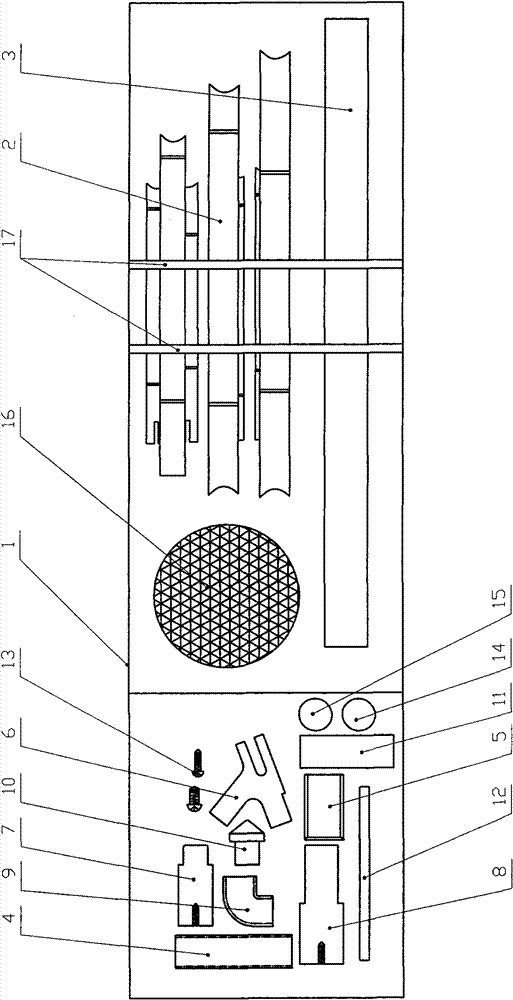

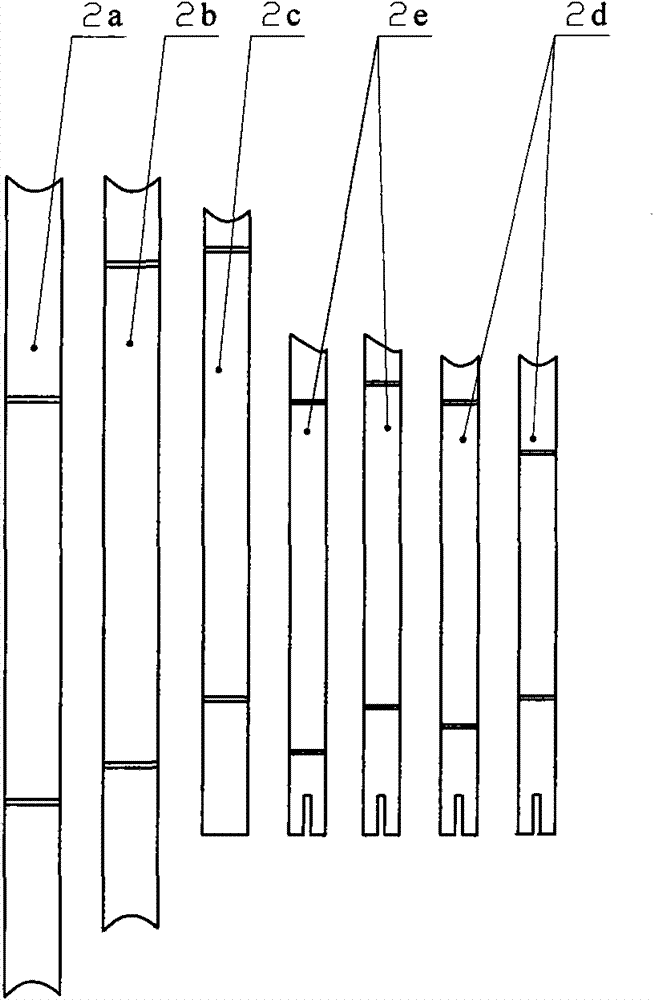

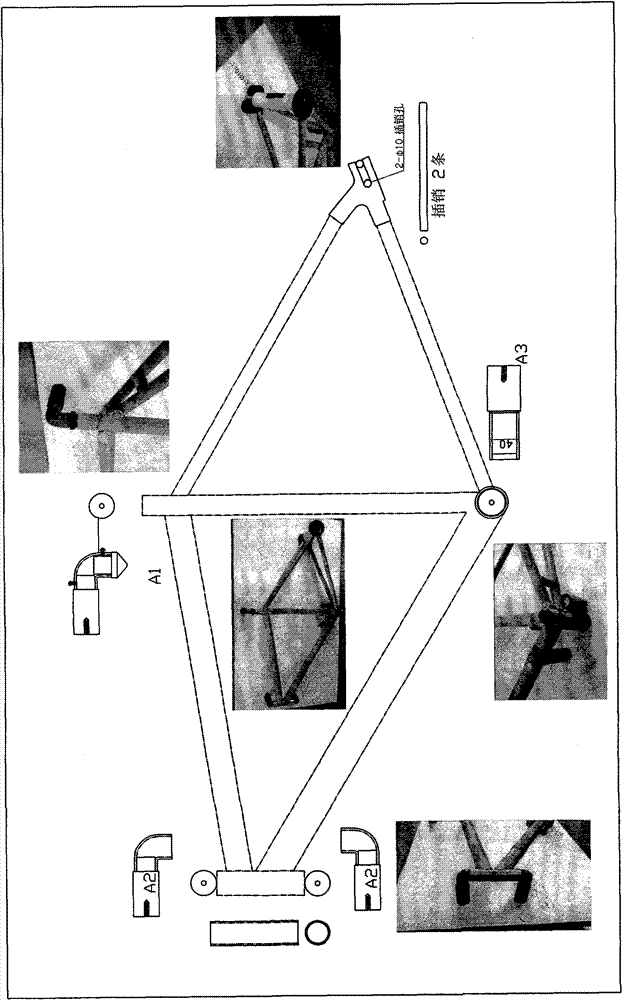

[0030] Figure 1 ~ Figure 4 Shown is an embodiment of the invention. Such as figure 1 As shown, the combined set product of the bamboo bicycle frame of the present embodiment includes a box body 1, a frame pipe fitting 2, an assembly drawing 3, a head tube 4, a rear down tube 5, two rear tail forks 6 and clamp fittings. Wherein, the box body 1 is in the shape of a cuboid. The frame pipe fittings 2 are bamboo upper tube 2a, lower tube 2b, standpipe 2c, two rear upper fork pipes 2d, two rear lower fork pipes 2e (see figure 2 ), placed side by side with the assembly drawing 3 at one end of the box body 1, and separated by cardboard 17 (the cardboard 17 is provided with a round hole, and the frame pipe fitting 2 and the assembly drawing 3 are inserted in the corresponding round hole). The head pipe 4, the rear down pipe 5, and the fixture accessories are placed at the other end in the box body 1. The fixture accessories include a short fixing seat 7 , a long fixing seat 8 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com