Miniature black body radiation source and preparation method thereof

A black body radiation source, miniature technology, applied in the field of infrared radiation source, can solve problems such as unintuitive, complicated temperature control methods, poor versatility, etc., and achieve the effect of easy acquisition, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

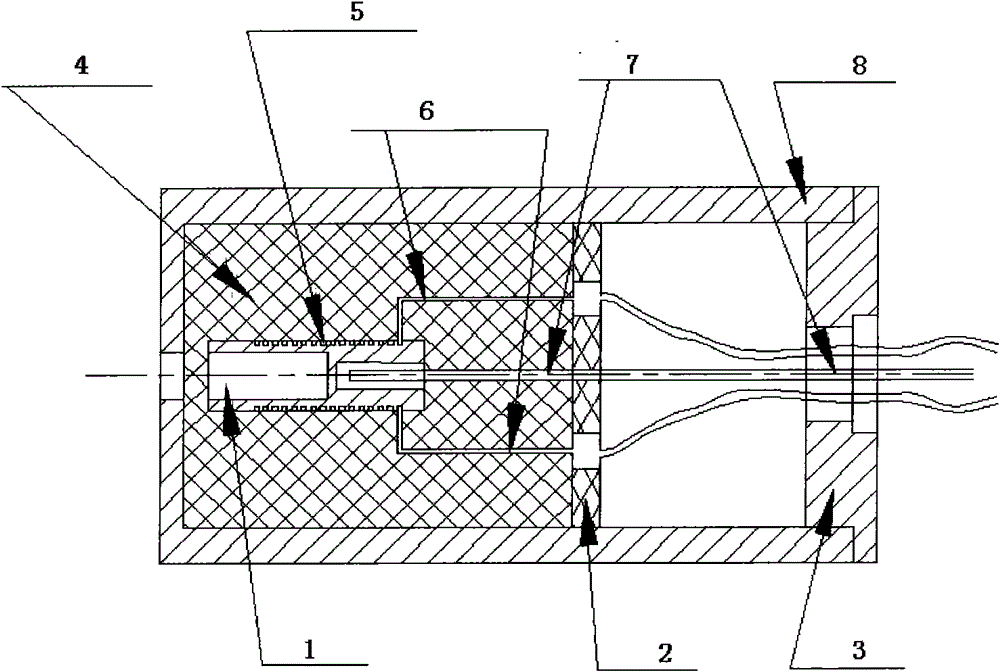

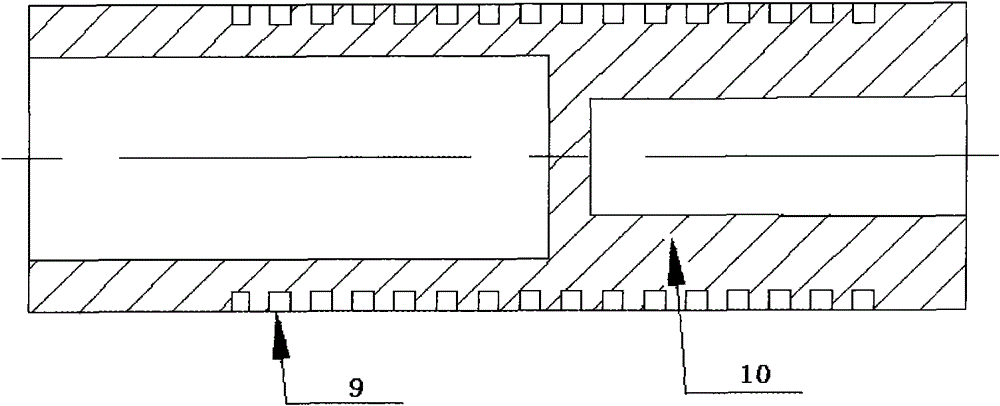

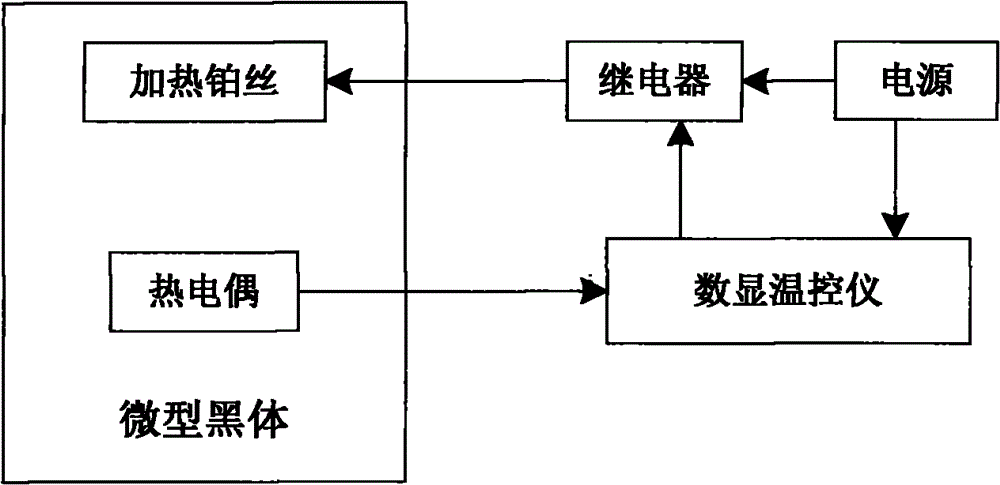

[0021] The miniature blackbody radiation source of the present invention is composed of a radiator, a thermocouple, and a digital display temperature controller. Such as figure 1 Shown is a miniature blackbody radiation source, including a radiation chamber 1, a lining ring 2, an end cap 3, a high-alumina fiber cloth 4, a heating platinum wire 5, a lead wire 6 and an outer casing 8. The radiation chamber 1 is a cylindrical cavity structure to ensure Blackbody radiators have high emissivity and temperature uniformity. figure 2 Shown is a mandrel, and one end of the mandrel 10 is a cylindrical radiation chamber 1 , and the other end is a thermocouple hole. It is made of stainless steel, and the surface is oxidized at 800±20°C. The outer surface of the mandrel 10 is coated with a high-temperature resistant insulating layer. The outer diameter of the mandrel is 3mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com