Rice washer

A rice grain and motor technology, which is applied in the field of kitchen utensils, can solve the problems of high manufacturing and use cost, huge volume, and more kitchen space, etc., and achieves the effects of high rice washing efficiency, simple operation and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

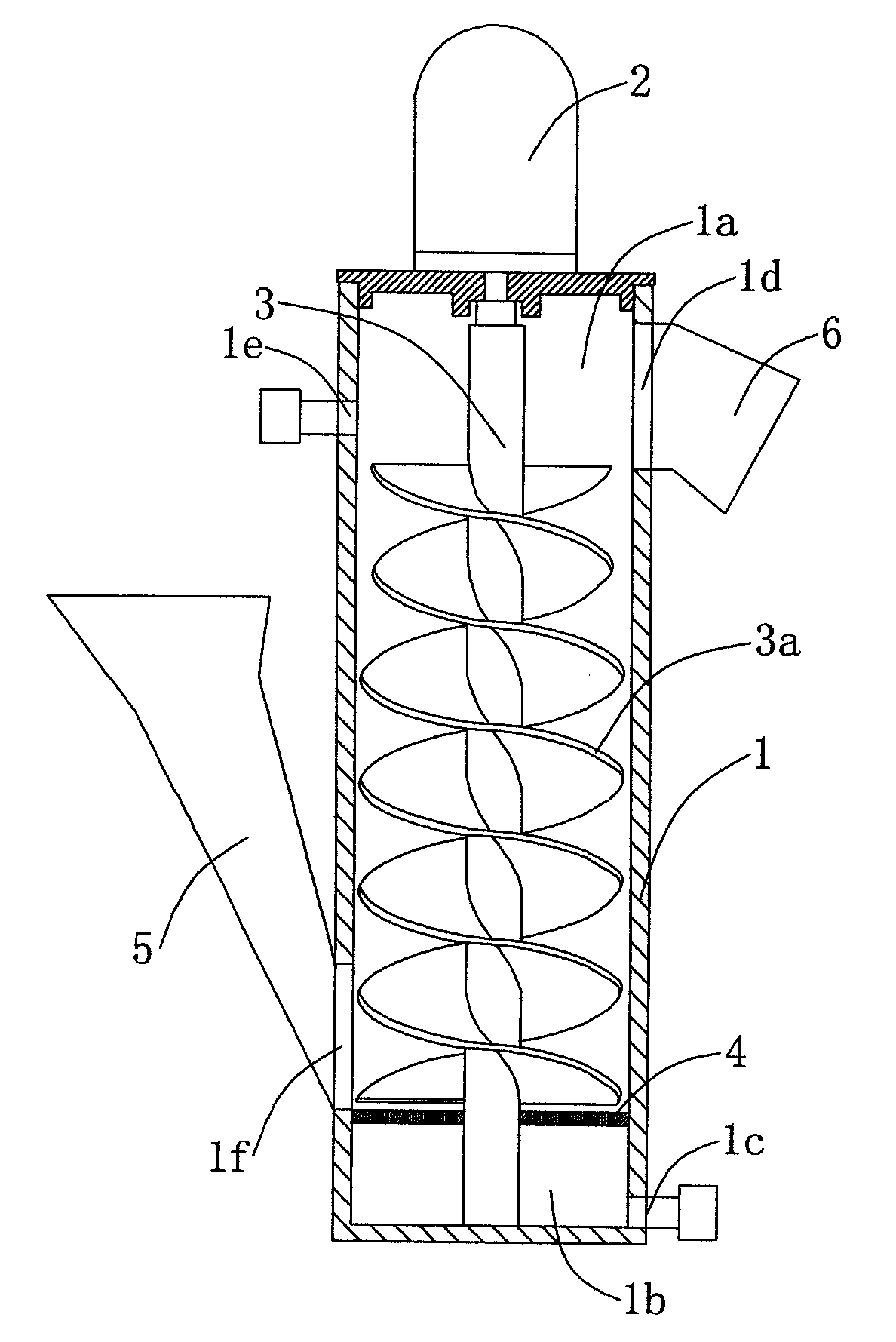

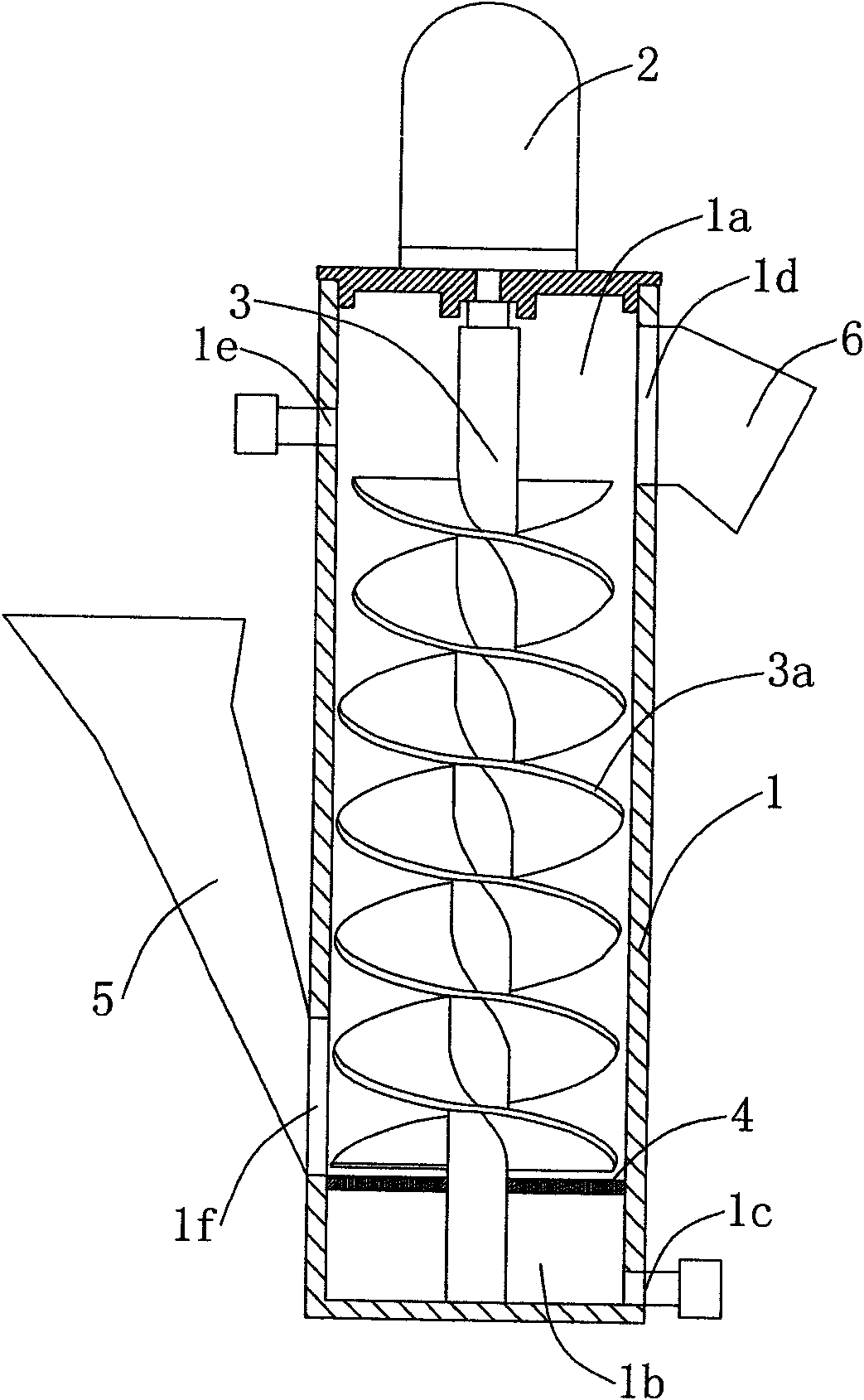

[0023] The rice washing machine of the present invention includes a casing 1, the casing 1 has a cylindrical inner cavity 1a for washing rice, a screw rod 3 driven by a motor 2 is arranged in the inner cavity 1a for washing rice, and a screw rod 3 is formed on the outer circumference of the screw rod 3 for conveying rice grains. Upward moving vanes 3a. A spacer 4 with sieve holes is fixed at the bottom of the inner cavity 1a for washing rice. The spacer 4 has a drainage cavity 1b under the spacer 4, and the drainage cavity 1b is provided with a drainage port 1c. The upper part of the inner cavity 1a is provided with a rice outlet 1d and a water inlet 1e, and the lower part is provided with a rice inlet 1f.

[0024] The separator 4 in the present invention can be a sieve plate or a screen, and the sieve diameter of the separator 4 is smaller than the diameter of rice grains. The spacer 4 separates the rice washing cavity 1a from the drainage cavity 1b, preventing the rice grai...

Embodiment 2

[0028] On the basis of Embodiment 1, the outer diameter of the casing 1 of the rice washing machine in this embodiment is preferably 40 cm, the height of the casing 1 is preferably 80 cm, and the height of the rice feeding bucket 5 is preferably 60 cm.

Embodiment 3

[0030] On the basis of Embodiment 1, the rice washing machine of this embodiment is further improved, and lines can be made on the upper surface of the rotating blade 3a to increase the conveying efficiency of rice grains in the rice washing cavity 1a. The rotary vane 3a spirals around the screw rod 3, and the thickness of the rotary vane 3a increases from bottom to top. The lower part of the rotary vane 3a is thicker, which can prevent rice grains from being crushed, and can increase the service life of the rotary vane 3a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com